Introduction

The EDI and supply chain revolution transform how lumber and building materials companies do business today. EDI (Electronic Data Interchange) can reduce order processing time by an impressive 50% to 60%, creating significant efficiency gains throughout the supply chain. This digital communication framework remains vital in modern business, with approximately 70% of B2B transactions still handled through EDI systems.

Electronic data interchange in supply chain management offers unique advantages for the lumber and building supplies industry. Supply chain costs typically eat into manufacturing profits by about 13%, making streamlined EDI processes essential for maintaining competitive margins. Additionally, the continued 11% annual growth of the EDI market demonstrates its expanding importance for managing the complex requirements of timber suppliers and building materials companies.

What is EDI, and How Does it Apply to the Lumber Industry?

Electronic Data Interchange (EDI) is the backbone of modern supply chain communication.

It is a digital language that allows computers to exchange information seamlessly.

Unlike traditional communication methods such as fax, mail, or email, EDI creates a standardized framework for businesses to share critical documents electronically without human intervention.

Understanding EDI in Supply Chain Management

At its core, EDI converts business documents into standardized digital formats that different computer systems can interpret automatically.5

These standards include

That ensures consistency across all trading partners. This standardization allows lumber companies and their suppliers to communicate regardless of what internal systems they might be using.

The fundamental difference between EDI and simple electronic mail lies in its structured format and direct system integration. Consequently, when a lumber distributor sends a purchase order via EDI, the document travels directly from their ordering system into their supplier’s sales system without anyone needing to manually enter the data.

This automated exchange encompasses crucial supply chain information including:

- Shipping details and delivery schedules

- Real-time inventory levels and product specifications

- Order updates and acknowledgments

- Payment processing and invoicing

Furthermore, electronic data interchange in supply chain management removes the risks associated with manual processing. Studies show that EDI order processing can reduce traditional order-to-shipment cycles by 50 to 60 percent, making it particularly valuable in an industry where the timely delivery of building materials is essential.

The magic behind EDI lies in its ability to convert documents like purchase orders or invoices into a standardized digital format that allows different systems to communicate effortlessly, ensuring consistency across the global lumber trade.

Why EDI Matters for Building Materials and Timber Suppliers

For the lumber and building materials industry, EDI processes represent a critical competitive advantage. The construction industry has a specific need to electronically transmit standard documents between designers, owners, contractors, and material suppliers. Through EDI, companies can efficiently exchange purchase orders, requests for quotations, invoices, shipping notifications, material lists, and payment transfers.

Consider the practical workflow: when a building supplier prepares an order in their system and sends it via EDI, the provider converts it into an ORDERS message and forwards it to the lumber supplier.

The order loads immediately into the supplier’s system, requiring just one click to process. This eliminates manual printing, sending, and data entry while providing confirmation that the supplier has received and accepted the order.

Once the lumber supplier ships the order, they send a delivery advice (DESADV message) through their EDI process flow, allowing the customer to prepare for receipt. When complete, an electronic invoice (INVOIC) automatically loads into the customer’s system, where it can be matched with corresponding documents and posted if everything aligns correctly.

Major players in the lumber industry have already embraced this EDI technology. Companies like 84 Lumber, Georgia-Pacific, Tolko, EACOM Timber, and many others use EDI to automatically exchange transaction and inventory documents with trading partners. These implementations have proven especially valuable for businesses handling thousands of suppliers and processing millions of orders and invoices annually.

Beyond efficiency, EDI in supply chain management provides enhanced security. EDI solutions are designed with strict access controls for authorized users only and typically include archive tracking and audit capabilities. This makes them ideal for confidential transactions involving large lumber shipments or custom building material orders.

For the construction market specifically, electronic data interchange supply chain solutions are penetrating rapidly as companies seek to reduce unnecessary administrative costs and prepare for potential market fluctuations. By eliminating printed purchase orders, manual entry of receipts, and paper-based invoices, lumber companies can significantly reduce operational expenses while improving accuracy across their entire supply chain.

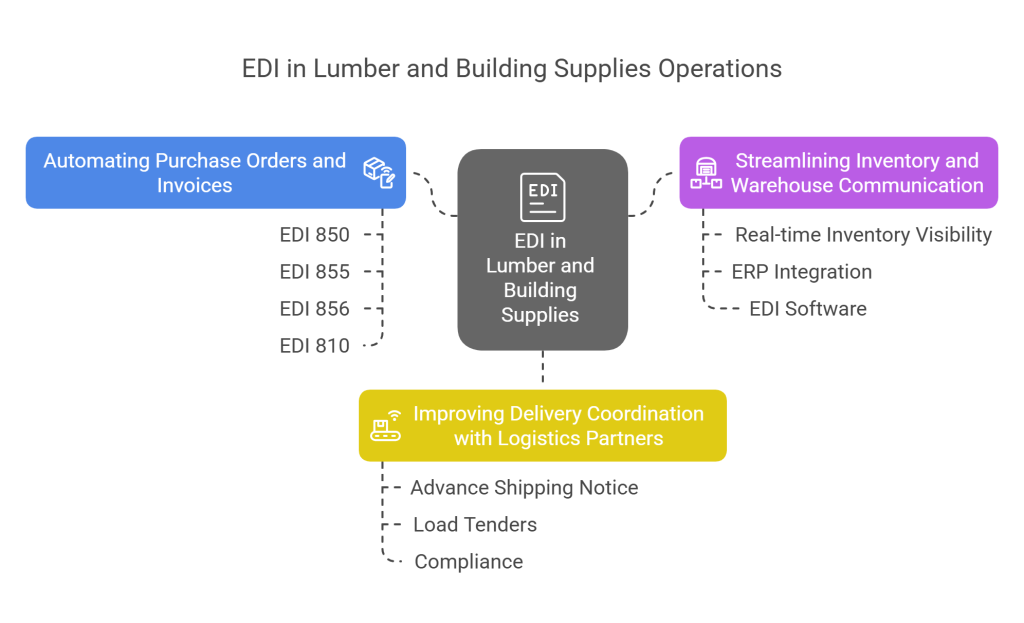

How EDI is used in Lumber and Building Supplies Operations

For lumber and building materials companies, implementing EDI creates powerful operational efficiencies across three critical business functions. The standardized electronic documents replace time-consuming manual processes, allowing businesses to focus on growth rather than paperwork. Let’s examine how these implementations work in practice.

1. Automating purchase orders and invoices

In the lumber industry, EDI dramatically streamlines the order-to-cash cycle, reducing processing times by up to 50% through automated document exchange. This automation begins when a buyer creates an electronic purchase order (EDI 850) in their system, which travels directly to the supplier’s order management system without manual intervention.

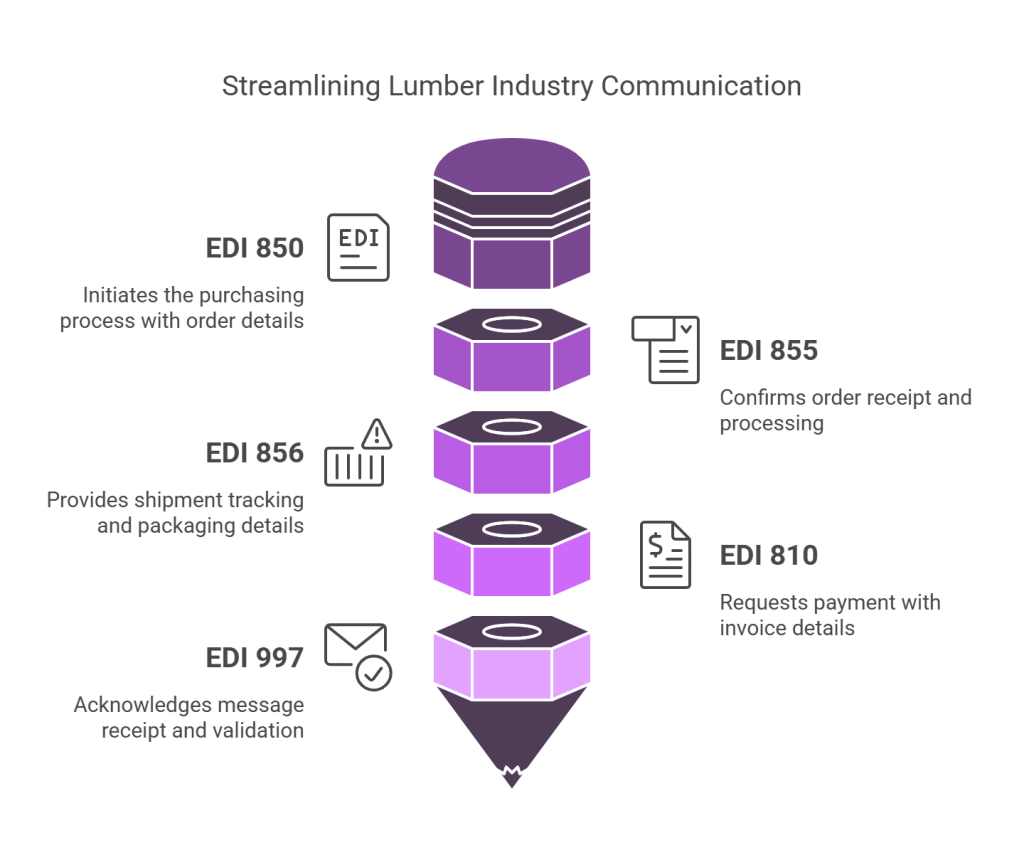

Upon receiving the order, the supplier’s system automatically generates an acknowledgment (EDI 855) confirming receipt. When the lumber shipment is ready, the system creates an advanced shipping notice (EDI 856) and ultimately an invoice (EDI 810) – all without requiring manual data entry.

This automation offers exceptional benefits for lumber companies:

- Elimination of costly data entry errors that plague manual systems

- Reduction in administrative costs to less than $10.00 per invoice

- Faster payment cycles, improving cash flow management

- Enhanced relationships with suppliers through timely, accurate transactions

For many lumber distributors working with major retailers like Lowe’s or Home Depot, EDI automation isn’t just beneficial—it’s essential. These trading relationships typically require EDI compliance, making it a prerequisite for accessing valuable sales channels.

2. Streamlining inventory and warehouse communication

Beyond order processing, EDI creates remarkable efficiencies in inventory management throughout the lumber supply chain. When properly implemented, EDI enables real-time visibility into inventory levels, allowing for better planning and reducing the risk of stockouts or overstock situations.

For warehouses specifically, EDI frameworks enable quick turnaround times by rapidly processing product information and tracking real-time movement of goods across the supply chain network. Personnel managing lumber inventory can automatically update their records through EDI systems connected to internal computers, alerting external vendors and suppliers about the current inventory status.

Moreover, EDI integration with enterprise resource planning (ERP) systems allows lumber companies to maintain accurate inventory counts across multiple locations. This integration is particularly valuable given the physical nature of lumber products, which require careful tracking of dimensions, grades, and treatments. Commport’s Electronic Data Interchange Solutions, for instance, help lumber companies securely place orders with major industry wholesalers and co-ops while also receiving remittance advice, invoices, price updates, catalog updates, and item images.

3. Improving delivery coordination with logistics partners

EDI helps coordinate deliveries between lumber suppliers and their logistics partners. EDI technology fulfills dual functions, enabling suppliers to notify companies about incoming warehouse shipments and helping businesses inform transportation agencies about orders requiring distribution.

The cornerstone of this coordination is the advance shipping notice (the ANSI X12 EDI 856 message) – an electronic document containing detailed information on shipment contents. This real-time data exchange allows logistics managers to know precisely which items they’ll receive from suppliers, enabling effective planning of warehouse operations.

Indeed, the benefits extend to all logistics activities:

- Transforming load tenders for enhanced operations, even during capacity reductions or shipment holds

- Allowing near real-time tracking of shipment status, including pickup, in-transit, and delivery information

- Evaluating carrier performance through real-time analysis of transit times and schedules

Additionally, EDI helps lumber companies maintain compliance with emerging industry regulations and standards. Major retailers often impose specific EDI requirements, and companies like Commport Communications provide solutions that ensure ongoing EDI compliance through automatic EDI mapping updates.

As lumber businesses expand their trading partner networks, EDI provides the foundation for scalable growth. The technology’s standardization allows new partners to be onboard quickly while maintaining consistent communication across the entire supply chain ecosystem.

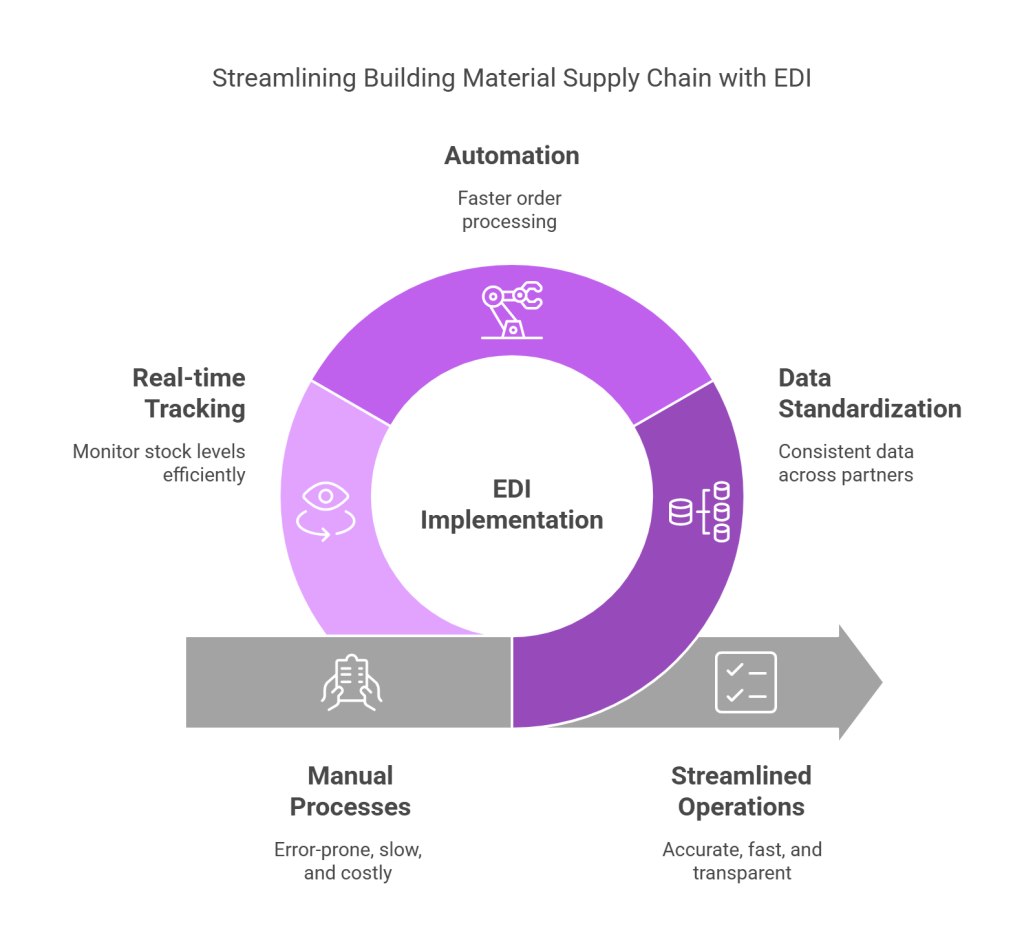

Key Benefits of EDI in the Building Materials Supply Chain

Implementing EDI across the building materials supply chain delivers measurable advantages that directly impact the bottom line. As lumber yards and building material suppliers navigate complex logistical challenges, electronic data interchange offers substantial benefits through improved accuracy, faster processing times, and enhanced transparency throughout operations.

1. Reducing Manual Errors and Paperwork

Traditional paper-based processes create significant vulnerabilities within building materials supply chains. Studies reveal that up to 20% of all manually entered invoice data contains typing errors, a statistic that represents potentially thousands of costly mistakes annually for busy lumber yards.

EDI effectively eliminates these concerns by removing manual data entry from the equation. When transaction data moves electronically between systems, the information remains consistent and accurate throughout its journey. This standardization creates several advantages:

- Elimination of errors associated with manual processing

- Consistency in data interpretation across all trading partners

- Removal of costs related to physical document storage and handling

- Significant reduction in time spent on error correction

Beyond accuracy improvements, EDI technology is generally credited with reducing paperwork and data transmission costs. For timber suppliers handling thousands of transactions monthly, this translates into substantial operational savings through the elimination of printed purchase orders, manual receipt entry, and paper-based invoices.

2. Faster Order Processing and Fulfillment

Within the lumber and building materials sector, transaction speed creates a competitive advantage. EDI dramatically accelerates order processing by automating document exchange between trading partners. This automation allows companies to process orders, invoices, and shipping notices considerably faster than traditional methods.

Upon implementing EDI solutions, businesses typically experience:

First, transaction processing speeds increase dramatically as information transmits instantly between trading partners. This real-time exchange reduces lead times for orders and payments, allowing lumber companies to respond more rapidly to market demands.

Second, automated order processing through EDI results in quicker order fulfillment and shorter cash cycles. The elimination of manual steps means that orders flow through systems in minutes rather than days, subsequently improving cash flow management throughout the supply chain.

Third, EDI technology significantly contributes to improved project schedules, an essential factor for construction industry partners who rely on the timely delivery of building materials. By securing faster, more accurate order fulfillment, EDI naturally leads to higher customer satisfaction and retention rates.

3. Improved visibility across the supply chain

Perhaps the most transformative benefit of EDI implementation is the unprecedented visibility it provides throughout the supply chain. For timber yards managing diverse inventories, EDI enables real-time tracking and monitoring of stock levels, thus removing guesswork from purchasing decisions.

This enhanced transparency delivers multiple operational advantages:

- Real-time visibility into transaction statuses, allowing for proactive issue resolution before problems escalate

- Improved coordination between suppliers, manufacturers, logistics providers, and retailers through efficient data exchange

- Enhanced ability to track shipments and monitor supplier performance with automated alerts for potential delays

- Better inventory management through accurate, timely shipping notifications

With EDI systems providing full transparency and end-to-end visibility into critical business processes, lumber companies gain access to accurate, real-time data for optimizing inventory planning and enhancing demand forecasting. This visibility enables better monitoring and control of business processes, therefore improving decision-making and responsiveness to market changes.

Altogether, EDI offers timber yards and building materials suppliers a powerful tool for maintaining optimal stock levels while simultaneously reducing carrying costs and preventing stock-outs. Through improved data accuracy, faster processing, and comprehensive visibility, EDI transforms supply chain operations from a potential liability into a genuine competitive advantage.

Common EDI Documents Used in the Lumber Industry

The lumber industry relies on several standardized EDI documents to facilitate seamless communication across the EDI supply chain. These electronic formats replace traditional paperwork, creating a consistent framework for exchanging critical business information between trading partners.

1. EDI 850: Purchase Order

The EDI 850 serves as the digital equivalent of a paper purchase order in electronic data interchange supply chain systems. This document initiates the purchasing process when a buyer places an order for lumber or building materials with a supplier. The transaction set contains essential elements, including:

- Item descriptions, quantities, and pricing

- Shipping instructions and delivery dates

- Payment terms and potential discounts

For lumber yards, the EDI 850 streamlines orders through direct system-to-system communication. Upon receiving this document, suppliers typically respond with acknowledgments and eventually invoices, creating a complete digital trail of the transaction.

2. EDI 855: Purchase Order Acknowledgment

After receiving an EDI 850, lumber suppliers send an EDI 855 Purchase Order Acknowledgment to confirm receipt and processing of the order. This document serves multiple purposes in the EDI process:

- Confirming the entire order or specific line items

- Indicating item status (accepted, rejected, or backordered)

- Communicating expected ship and delivery dates

The EDI 855 effectively eliminates the need for lumber suppliers to confirm orders via phone, email, or fax. For buyers, it quickly alerts them to any potential supply issues, preventing later problems with invoicing and payments.

3. EDI 856: Advanced Shipping Notice

The EDI 856 (ASN) functions as a detailed electronic packing list sent before shipment arrival. This critical document in EDI supply chain management provides comprehensive information about incoming deliveries:

- Shipment tracking details and carrier information

- Item-level details, including quantities

- Packaging specifications (which items are in specific cartons/pallets)

For lumber distribution centers, ASNs are essential for planning labor and equipment needs based on upcoming deliveries. Many major retailers require timely ASN transmission, making it a compliance necessity for lumber suppliers serving these channels.

4. EDI 810: Invoice

The EDI 810 Invoice represents the electronic version of a traditional paper invoice, sent by lumber sellers to request payment. Like paper invoices, this document includes:

- Invoice number and date

- Order details with product quantities and prices

- Additional charges, discounts, or allowances

- Total amount due and payment terms

After receiving an EDI 810, buyers typically confirm receipt with an EDI 997 Functional Acknowledgment. Once verified as correct, the invoice moves to accounting for payment processing. For lumber suppliers, using EDI 810 accelerates payment cycles and improves cash flow management.

5. EDI 997: Functional Acknowledgment

The EDI 997 functions like a digital receipt confirmation within electronic data interchange in supply chain management. Unlike other transaction-specific documents, 997 simply confirms that a message was received and processed correctly by the recipient’s EDI system.

This acknowledgment provides:

- Confirmation of message receipt

- Syntax validation results

- Error reporting when applicable

In the lumber industry’s EDI processes, 997 ensures that critical documents like orders and invoices have successfully reached their destination. This creates accountability and transparency between trading partners, allowing for early identification of potential communication problems.

Ultimately, these five EDI document types form the backbone of electronic communication in the lumber and building materials supply chain, creating a standardized framework for efficient business operations.

Challenges in Implementing EDI with Diverse Trading Partners

Despite its many advantages, implementing EDI to optimize supply chain systems remains challenging, particularly when working with diverse trading partners across the lumber and building supplies industry. These hurdles often determine whether implementation succeeds or struggles to deliver its promised benefits.

1. Dealing with Legacy Systems and Varying Technical Capabilities

Legacy systems, once the backbone of operations, frequently struggle to keep pace with modern electronic data interchange in supply chain management requirements. Many lumber industry partners operate decades-old technologies that present significant limitations when attempting to integrate with newer EDI frameworks. The first critical step in overcoming these obstacles involves thoroughly assessing current systems to understand gaps and create a clear migration roadmap.

Nevertheless, technical capabilities vary dramatically across the lumber supply chain. While large retailers may demand sophisticated EDI processes, smaller lumber yards and suppliers often lack the infrastructure to support complex implementations. This disparity creates integration challenges that can disrupt critical business operations.

For many organizations, implementing in-house EDI solutions proves prohibitively expensive, with significant costs related to infrastructure, external mapping consultancy, software licensing, and ongoing employee training. As trading partner networks expand, managing these diverse integrations becomes increasingly challenging, presenting serious scalability concerns.

2. Ensuring Data Standardization and Compliance

Although EDI supply chain management depends on the standardization, the reality is quite different. Trading partners frequently have unique EDI requirements that necessitate compliance to maintain business relationships. Major retailers like Walmart exemplify this complexity, requiring specific document formats, continuous secure connections, and rigorous testing before allowing suppliers to send live transactions.

Another significant hurdle involves the incompatible standards that leave computer systems unable to understand each other, ultimately complicating rather than simplifying supply chain processes. Even within standard EDI formats like EDIFACT, documents weren’t designed for human readability, making error detection both challenging and time-consuming.

One frustration stems from the misconception that EDI represents a single standard, whereas industries and companies often create their own specific rules and modifications. This proliferation of standards means lumber suppliers frequently encounter partner formats whose systems cannot natively understand.

3. Training and Onboarding for Smaller Suppliers

Change management becomes paramount when introducing new electronic data interchange supply chain systems. Proper training and communication can reduce friction and ensure smooth adoption of new workflows and processes. Without adequate preparation, team members may overlook key features, resulting in inefficiency, increased errors, and reduced employee satisfaction.

Smaller lumber suppliers face unique barriers, including the need to acquire new skills and implement unfamiliar infrastructure. Even with training, establishing clear processes for exception handling remains essential, as anomalies invariably occur despite careful planning.

To address these challenges, many lumber industry partners turn to web-based EDI solutions offering training and 24/7 support. Ultimately, successful implementation requires cross-disciplinary teams incorporating members from various departments to ensure a comprehensive understanding of operations, processes, and skill sets.

Best practices for successful EDI integration in lumber supply chains

Successful implementation of EDI supply chain solutions requires strategic planning and careful execution. For lumber companies seeking to maximize their return on investment, following these proven best practices can pave the way for seamless integration.

1. Start with high-volume transactions

The path to successful electronic data interchange supply chain adoption begins with identifying and implementing your highest-volume transactions first. Initially, focusing on routine documents like purchase orders and invoices from major trading partners yields immediate productivity gains. This approach allows lumber companies to:

- Eliminate re-keying of frequently exchanged documents

- Hasten order processing for major retailer relationships

- Build confidence in the system through early wins

Trading with big box retailers like Lowe’s or Home Depot becomes significantly less complicated once these high-volume transactions are automated, creating a foundation for broader implementation.

2. Integrate EDI with ERP and Inventory Systems

Connecting EDI processes with enterprise resource planning systems creates a powerful pipeline between internal operations and external partner communications. Upon integration, lumber companies experience:

First, reduced costs through minimized errors and their associated business expenses. Second, process optimization that accelerates business cycles through automated pipelines. Third, improved visibility by creating a single source of truth for inventory and supply chain data.

This integration enables automated stock replenishment without human intervention, as purchase orders are triggered automatically when ERP data indicates low inventory levels, a critical advantage in managing diverse lumber products.

3. Monitor and optimize EDI processes regularly

Ongoing system monitoring forms an essential part of EDI process maintenance. Regular health checks help identify anomalies in system activities before they become problems. Once implemented, track performance metrics include data processing time and transaction completion rates.

Additionally, establish robust error reporting mechanisms to spot issues early. Lumber companies should conduct periodic integration efficiency assessments to ensure the system functions at peak performance. As organizations master basic EDI functions, they can expand to more complex transactions, gradually increasing automation across the entire supply chain.

Conclusion

Throughout this blog, we’ve examined how electronic data interchange transforms lumber and building materials supply chains. Above all, EDI offers substantial competitive advantages through standardized digital communication that significantly reduces manual errors while accelerating order processing. Consequently, businesses implementing EDI typically experience 50% to 60% faster order cycles, creating operational efficiencies that directly impact profitability.

The benefits extend well beyond speed alone. EDI effectively eliminates costly paperwork, streamlines inventory management, and provides unprecedented visibility across complex supply networks. Additionally, standardized documents like EDI 850 purchase orders and EDI 856 advance shipping notices create a universal language for trading partners regardless of their systems.

Despite clear advantages, implementation challenges remain, particularly when working with partners using legacy systems or lacking technical capabilities. Therefore, successful EDI adoption requires strategic planning—starting with high-volume transactions, ensuring proper integration with existing ERP systems, and establishing ongoing monitoring protocols. Companies that follow these best practices position themselves for streamlined operations and stronger trading partner relationships.

As lumber and building materials businesses face increasing pressure to optimize operations and reduce costs, Switch to Commport EDI Solutions for specialized expertise in connecting your business to major retailers, suppliers, and logistics partners. The continued growth of EDI adoption—expanding at 11% annually—underscores its essential role in modern supply chain management.

Undoubtedly, EDI represents more than just a technological upgrade; it fundamentally transforms how lumber companies conduct business. Organizations embracing these digital frameworks gain not only operational efficiencies but also enhanced customer satisfaction through faster fulfillment and improved accuracy. For lumber yards and building materials suppliers seeking a competitive advantage in today’s market, comprehensive EDI implementation has become not merely beneficial but essential.

Commport EDI Solutions

Need Help? Download: Commport's EDI Buyers Guide

Unlock the full potential of your supply chain with our comprehensive EDI Buyer's Guide — your first step towards seamless, efficient, and error-free transactions

Frequently Asked Questions

EDI significantly improves efficiency in the lumber industry by reducing order processing time by 50% to 60%, automating document exchange, and providing real-time visibility across the supply chain. It helps in reducing manual errors, streamlining inventory management, and improving coordination with logistics partners.

The most common EDI documents in the lumber industry include EDI 850 (Purchase Order), EDI 855 (Purchase Order Acknowledgment), EDI 856 (Advanced Shipping Notice), EDI 810 (Invoice), and EDI 997 (Functional Acknowledgment). These documents facilitate seamless communication between trading partners.

Major challenges include dealing with legacy systems, varying technical capabilities among trading partners, ensuring data standardization and compliance, and training staff, especially for smaller suppliers. Overcoming these hurdles requires careful planning and often specialized solutions.

Successful EDI integration involves starting with high-volume transactions, integrating EDI with existing ERP and inventory systems, and regularly monitoring and optimizing EDI processes. This approach helps in maximizing ROI and ensuring smooth adoption across the organization.

Yes, EDI adoption has become essential for lumber and building materials businesses. With the EDI market growing at 11% annually, it’s crucial to optimize operations, reduce costs, and maintain competitiveness. Many major retailers now require EDI compliance from their suppliers, making it a necessity for accessing valuable sales channels.