Before we get started on how to optimize and improve supply chain efficiency, it is important to define and know what is supply chain management and its importance in the end-to-end delivery of final products to customers.

What is supply chain management?

Supply chain management is the process of managing and perfecting procurement, the flow of materials, and the delivery of products and services from source to destination (i.e., from suppliers to customers). It involves integrating all the supply chain components such as planning, controlling, coordinating, and integrating suppliers, inventory control, manufacturing process, material handling, transportation management, and information technology. The main goal of supply chain management is to deliver value to customers while maximizing efficiency in cost and throughput time

What is supply chain efficiency?

In simple terms, supply chain efficiency means maximizing your supply chain output by reducing costs. It is how the resources are optimized to deliver goods and services to customers faster and on time with minimal cost. Other factors also affect your supply chain efficiencies such as operations capabilities, inventory demand from customers, and technology challenges.

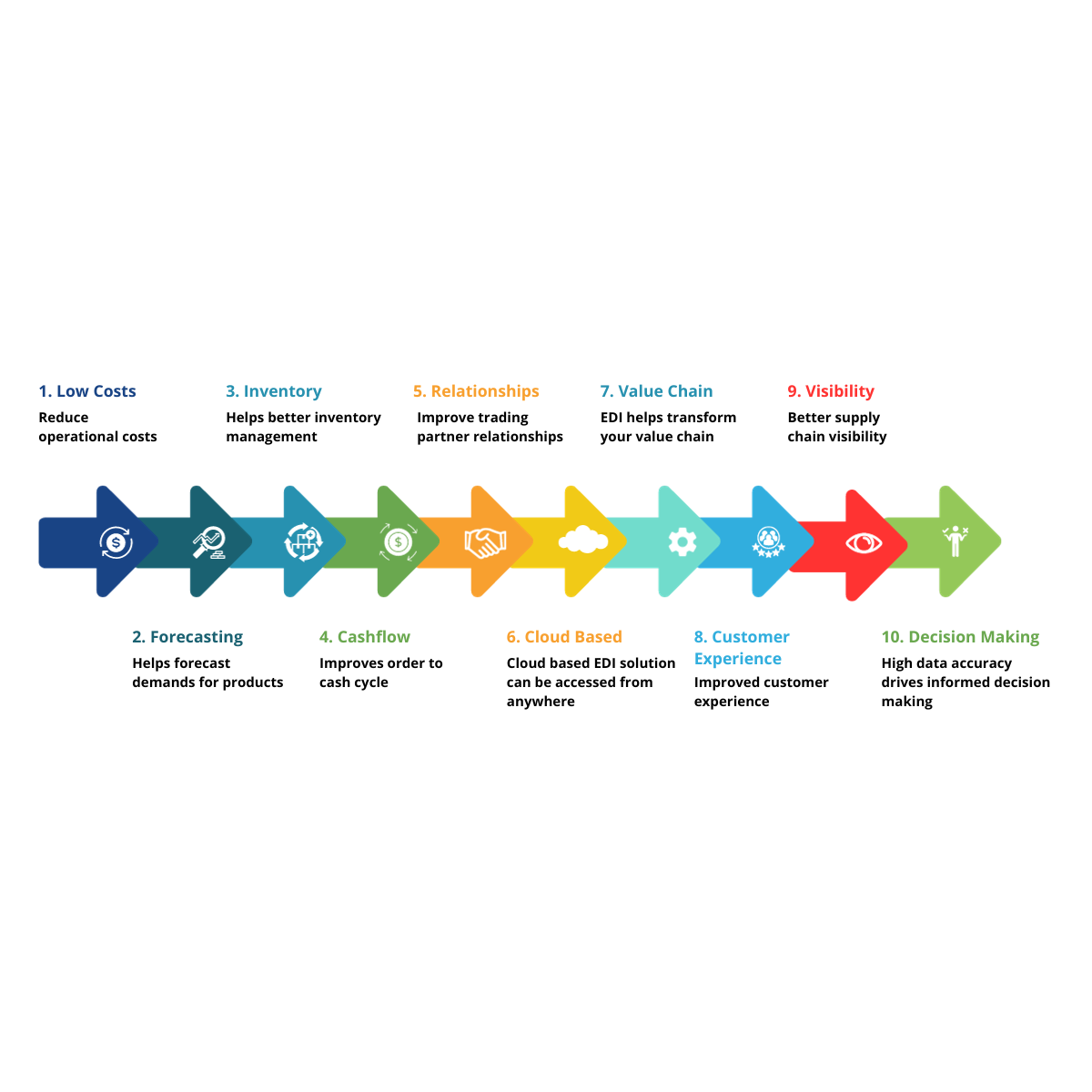

1. EDI helps brings down your supply chain operational costs significantly

To reduce your operational costs, the first thing you need to estimate is which customers drive the highest level of revenue to your business. Conduct an effective cost-to-serve analysis and this can be done with accurate and real-time invoicing using EDI.

Once you have a detailed cost-to-serve analysis you can accurately estimate the profit margins for each customer and identify the ones that are not profitable and then you can optimize your supply chain to do things differently and more efficiently to reduce your operational costs by automating your order processing, inventory management and having greater control over your distribution networks.

Usually, mistakes in your purchase orders and invoicing can also lead to costly chargebacks for thousands of dollars from your business partners and these mistakes happen if you still process your data manually. This can be avoided by using EDI which can automate your entire B2B document exchange process in a standardized format that is widely accepted by all major retailers and make your business EDI-compliant.

2. EDI helps you forecast product demands to better plan your supply and demand needs

Effective EDI solutions update all your data such as orders, invoicing, shipping, returns, etc. in real-time. Access to such real-time data can help you forecast demand for certain products. Identifying which products are selling fast and which are not. This way a retailer can plan effective inventory management by stocking up for the products with high demand in advance and not keeping too much inventory for slow-moving products. All these forecasting metrics can help you better optimize your supply chain efficiency to get your products delivered on time to your customers.

3. EDI helps you with better inventory management with real-time data

Inventory management is crucial for all businesses. It’s not just about holding up stocks, but also how fast these stocks are moving out from the warehouse to customers. The longer the time the stock is held up in the warehouse the more costs are added to inventory management. A business using EDI for inventory management can check their stocks daily or hourly giving them real-time updates on stock movement, speeding up the order processing, and delivering products faster to customers by better-optimizing delivery routes. Also, the chance of errors in order processing is reduced significantly using EDI as it’s all processed automatically without manual intervention which in turn reduces any delays in order processing and reaching customers faster.

4. Improved order-to-cash-cycle

The order-to-cash cycle decides how fast the business receives the payment in full for the products purchased by the customers. The longer it takes, it affects the overall business cash flow, which in turn affects the net operating income for the business. In the manual process scenario, this could assume to 2 weeks because the business must fax the invoice to the customer and then the customer enters the invoiced data into the system manually and then tally the products purchased with goods received, and then makes the payment. This entire process delays the overall order-to-cash cycle process.

By using EDI this entire process can be automated and processed in minutes rather than days. Automated EDI systems can also integrate with other areas of your business inventory tracking, ERP software, or customer relationship management (CRM) programs for a more comprehensive view of all processes. Additionally, using dashboards or reporting tools can be crucial for analyzing key metrics like days sales outstanding (DSO) which shows how quickly customers are paying you.

5. EDI Improves trading partner relationships

Today almost 90% of all retailers require their vendors/suppliers to be EDI-compliant to do business with them. EDI makes it easy to exchange data electronically such as invoices, purchase orders, advance ship notices, and hundreds of other EDI document types. There are many EDI standards accepted by trading partners/retailers. But the 2 most popular EDI standards are EDI X12 and UN/EDIFACT standard.

Being EDI compliant means it’s an opportunity as a supplier to stand out from others who are not compliant and easily scale your business by exchanging EDI with all major retailers and gaining access to a global network of customers and retailers all over the world.

6. Using cloud-based EDI you can do business from anywhere

Cloud-based EDI solutions are the game changer for the EDI industry. It’s the most economical EDI solution and easy to use. The best part is you don’t need to install any complicated software. You can access it from anywhere in the world with just a computer and internet connection and you can begin exchanging EDI with your trading partner today. You don’t need to be an expert or require any complex training to use cloud-based EDI solutions, they have user-friendly interfaces. Also, it’s easy to keep track of all your EDI transactions in one single dashboard.

7. EDI helps transform your value chain

A value chain is a system of activities that starts with the task of supplying raw materials and ends with the delivery of a finished product or service. It looks at all the activities that are necessary to add value to a good or service as it flows through the supply chain, from suppliers to customers. Each step in the process adds value which can then be passed on to the end customer, resulting in profit for the company. By understanding the multiple stages of a value chain, companies can better manage costs and improve product or service quality.

EDI can play a key role in each stage of the value chain to improve your overall supply chain operational efficiency and reduce costs. This involves improving relationships with suppliers who can supply quality, cost-effective products that meet customer expectations. Additionally, suppliers should be able to support current and future demand for the products and keep open communication by providing continuous updates. With much valuable data, you can spot trends in real-time in understanding customer buying habits which allows you to optimize your value chain performance to better meet customer demands.

8. Improved customer experience

EDI helps streamline all your communications. Your customers can get an automatic update on orders, shipments, on-time delivery dates on time, returns and so much more. It enhances transparency by providing accurate information on their transactions. Makes the customer experience better and turns them into loyal customers.

9. Better supply chain visibility

EDI helps you with supply chain visibility by monitoring your supply chain performance in real-time, providing valuable insights on various resources with up-to-date information on the movement of goods and materials. All the data gathered can be used to optimize resource management, identify potential problems or delays in the supply chain and make improvements and reduce overall operational costs.

10. Improved data accuracy helps you make informed decisions.

As we already know, EDI makes data exchange easy by replacing the old paper-based system with electronic data exchange. It is not just the speed at which the data is exchanged is improved but also its accuracy. EDI makes sure you receive 100% accurate information without any errors that let you make informed decisions on various aspects of your supply chain to better scale its efficiency.

Want to learn more about how to improve supply chain efficiency?

Download this free guide.

Need Help? Download: EDI Buyers Guide

Unlock the full potential of your supply chain with our comprehensive EDI Buyer's Guide — your first step towards seamless, efficient, and error-free transactions

Frequently Asked Questions

Supply chain management is the process of managing and perfecting procurement, the flow of materials, and the delivery of products and services from source to destination

Supply chain efficiency means maximizing your supply chain output by reducing costs. It is the way in which the resources are optimized to deliver goods and services to customers faster and on time with minimal cost

Inventory management involves the process of overseeing and controlling the quantities of goods and materials that a business has on hand at any given time to ensure that the company can meet customer demand while minimizing the costs of holding excess inventory.

The Order-to-Cash (O2C) cycle refers to the set of processes that a company goes through to fulfill a customer order, from the initial receipt of the order through the receipt of payment for the goods or services delivered

Value chain refers to the sequence of activities that a company undertakes to create and deliver a product or service to its customers