Introduction Digital Transformation might sound like just another business buzzword, but the undeniable success of companies embracing it over the past decade proves it’s a powerful strategy. However, when digital experiences fall short, insufficient data management practices are often what’s holding organizations back. In today’s complex business environment, managing product information across multiple channels while maintaining […]

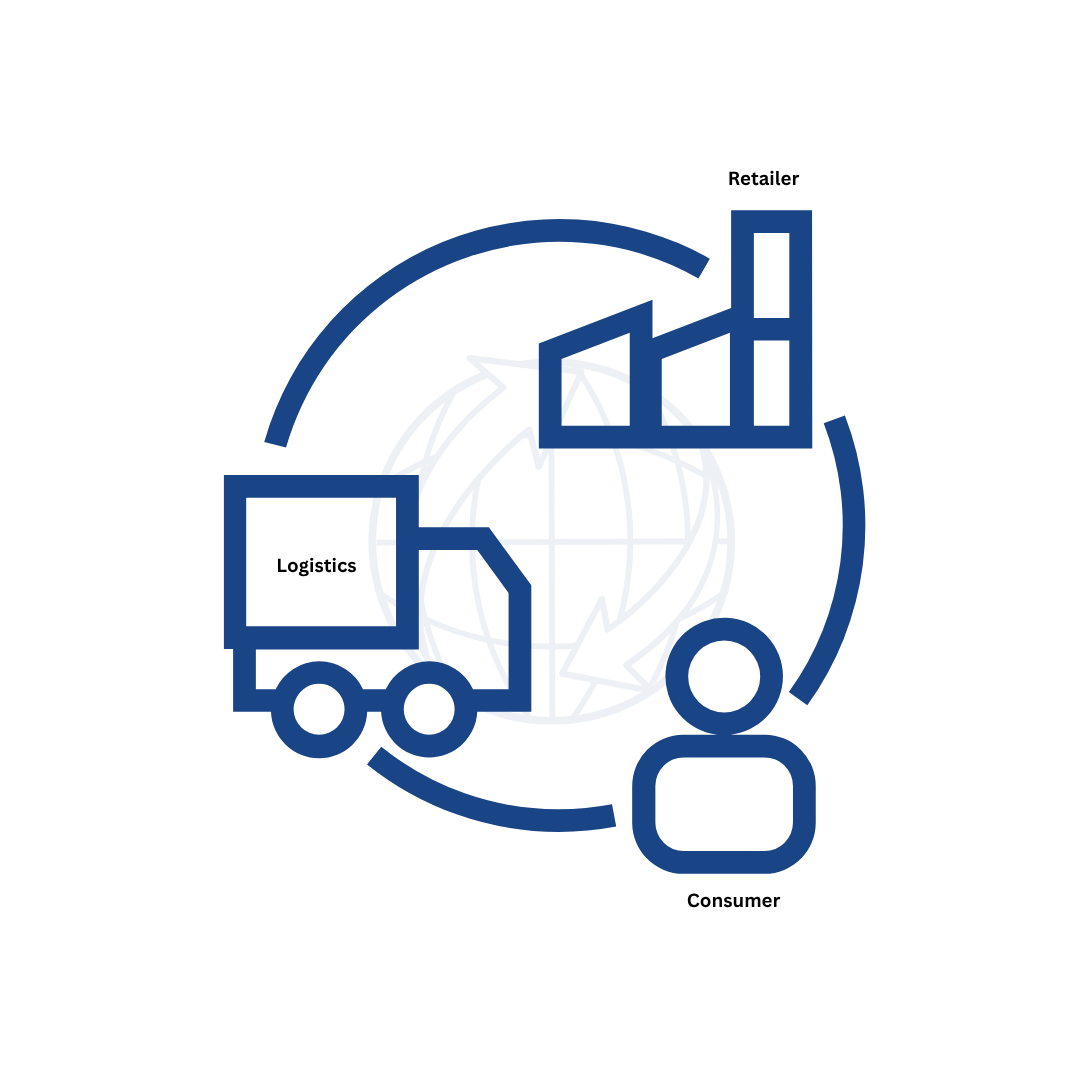

Introduction Supply chain visibility has become a critical factor for businesses seeking to prevent costly disruptions in today’s complex global marketplace. More than 80% of the typical consumer company’s greenhouse gas emissions are embedded in their supply chains, highlighting just one area where improved transparency delivers significant value. When we discuss supply chain visibility, we […]

Introduction With more than four trillion consumer products made, shipped, and sold globally every year, connected supply chain systems have become essential for businesses to manage this overwhelming complexity. We face a stark reality: according to MIT research, 81% of companies lack full visibility of their supply chains, while 54% admit having none at all. This visibility […]

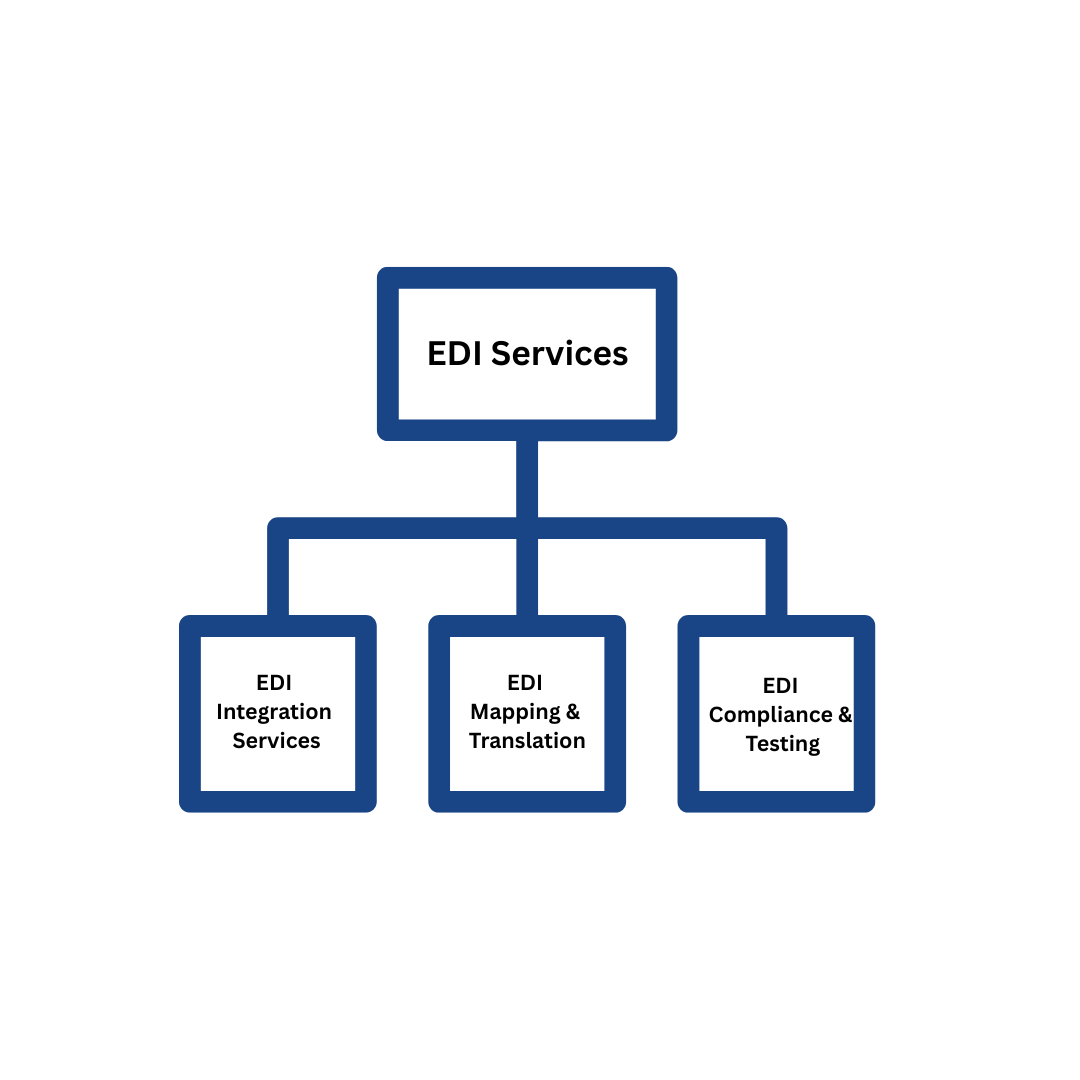

Introduction EDI services have transformed supply chains. These systems cut transaction processing times from weeks to just minutes or hours. We’ve witnessed how Electronic Data Interchange (EDI) improves efficiency in supply chain operations through instant data transmission between systems. Today’s market shows that 90% of retailers need their vendors to be EDI-compliant before doing business […]

Introduction: GDSN Explained: A Simple Guide for Retail Success GDSN has become a critical backbone for retail success, with over 40 million Global Trade Identification Numbers registered in the system by 2025. If you’re wondering what GDSN means and why it matters, you’re not alone – many retailers are still discovering its importance. 84% of consumers […]