Introduction

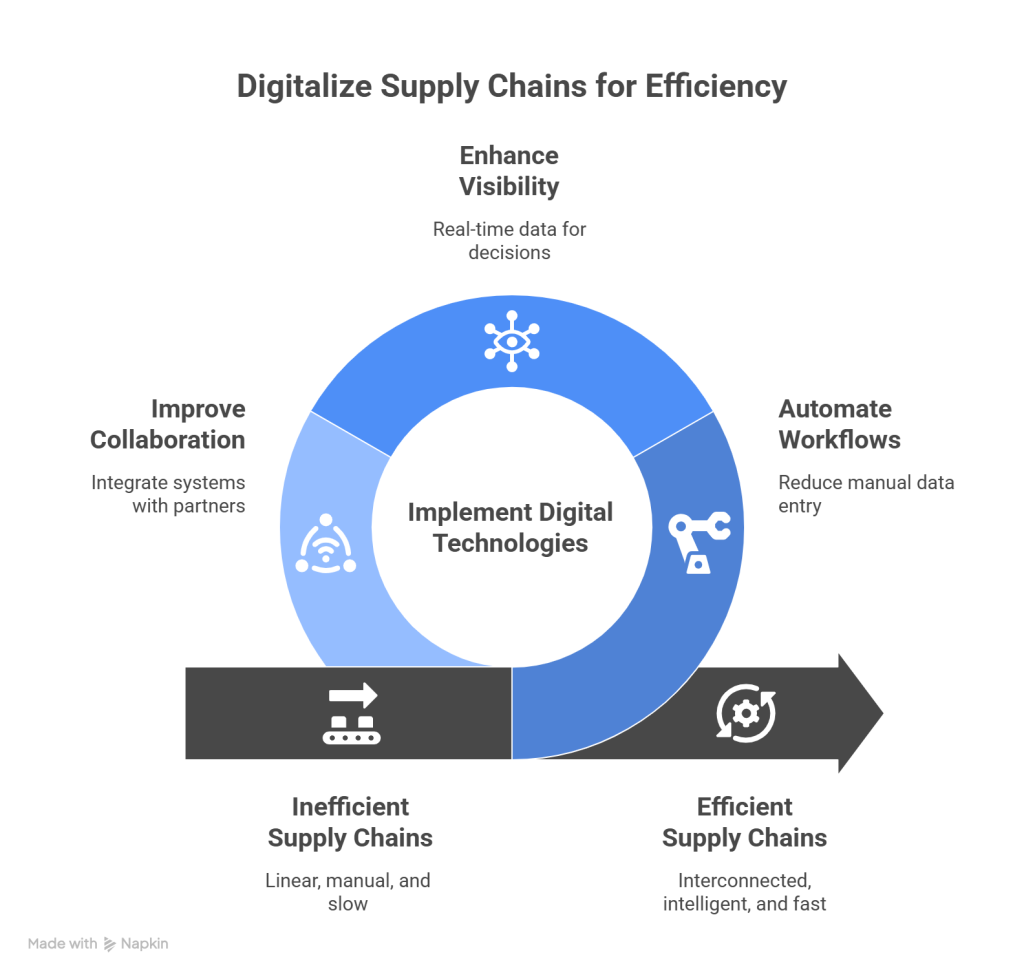

Supply chain digitalization represents a fundamental shift in how organizations operate, moving beyond simply digitizing paper-based processes. While many business leaders use the terms interchangeably, supply chain digitization refers to converting analog information into digital formats. In contrast, supply chain digitalization involves transforming operations using digital technologies to make them smarter, faster, and more integrated.

In this comprehensive blog, we’ll explore essential tools for mastering supply chain digitalization, including EDI, Value-Added Networks (VAN), Global Data Synchronization Network (GDSN), Product Information Management (PIM) systems, and supply chain analytics solutions. By the end, you’ll understand how these technologies work together to create end-to-end visibility and transform your supply chain operations.

Key Takeaways

- EDI drives massive cost savings: Companies report up to 35% operational expense reduction and 50-60% faster business cycles by automating document exchange through standardized formats like purchase orders (850) and invoices (810).

- VANs simplify partner connectivity: Value-Added Networks eliminate complex point-to-point connections, enabling businesses to reach multiple trading partners through one secure connection while reducing annual costs by 40-80%.

- GDSN ensures data accuracy: The Global Data Synchronization Network creates a single source of truth for product information, reducing data errors by 25% and increasing operational efficiency by 30% through real-time synchronization.

- PIM centralizes product management: Product Information Management systems improve data quality and consistency across all channels, directly influencing 87% of shoppers’ purchasing decisions through accurate product content.

- Integration creates end-to-end visibility: When EDI, VAN, GDSN, and PIM work together, they eliminate data silos and enable intelligent supply chain ecosystems that respond rapidly to disruptions and market changes.

Defining Supply Chain Digitalization

Supply chain digitalization encompasses the strategic implementation of technologies that turn traditional, linear supply chains into interconnected, intelligent networks. It involves harnessing digital tools to automate workflows, enhance visibility, and improve process efficiency.

Essentially, it’s the process of creating a data-driven ecosystem where information flows seamlessly within an organization and between external partners, allowing for real-time decision-making.

A digital supply chain is distinctly “on-demand” by nature, enabling companies to move rapidly from design to manufacturing through simple, quick steps.

According to research, organizations without solid digital supply chain infrastructure can expect up to 44% supply chain complexity and inefficiencies, creating significant barriers to growth.

Key Drivers: Speed, Accuracy, and Automation

Three primary forces drive supply chain digitalization:

- The need for speed,

- accuracy, and

- automation.

In today’s volatile business environment, companies require supply chains that can respond rapidly to changing conditions.

Consequently, over 85% of C-level executives anticipate that digitization efforts will enhance cash flow and reduce the Days Sales Outstanding (DSO) metric.

The financial implications are significant; organizations typically spend over USD 1 million annually on manual data entry into ERP systems, as well as more than USD 600,000 on manually entering supplier invoices.

Hence, automation stands as a primary driver, eliminating repetitive tasks and reducing human error while improving overall efficiency.

Digital supply chains enable multi-enterprise collaboration by dismantling data silos, allowing secure integration between systems of the organization and its external partners.

Moreover, when we examine highly digitalized companies (those reporting six to eight different digital activities), they took significantly more actions to mitigate supply chain disruptions than less digitalized ones.

How Digitalization Supports Global Trade Ecosystems

Digitalization plays a pivotal role in strengthening global trade ecosystems.

In the evolving landscape of international commerce, trade digitalization leverages information and communication technologies to revolutionize traditional trade processes.

This transformation enhances border controls and trade administration procedures, thus reducing trade costs and fortifying the resilience of global supply chains.

The World Trade Report notes that digital technologies significantly reduce trade costs while increasing the services component in trade and fostering the exchange of time-sensitive products.

Most importantly, research indicates that digital transformation has a substantial positive effect on supply chain resilience, both directly and indirectly, by strengthening supply chain power and transparency.

Looking at broader economic impacts, simulation studies show future technological changes are expected to increase trade growth, especially in services, with developing countries likely gaining an increasing share of global trade.

Nevertheless, realizing these benefits requires international cooperation to ensure digital trade continues driving inclusive economic development.

For supply chain professionals aiming to thrive in this digital era, understanding the foundational technologies—EDI, VAN, GDSN, and PIM—becomes essential for building resilient, efficient supply networks capable of meeting tomorrow’s challenges.

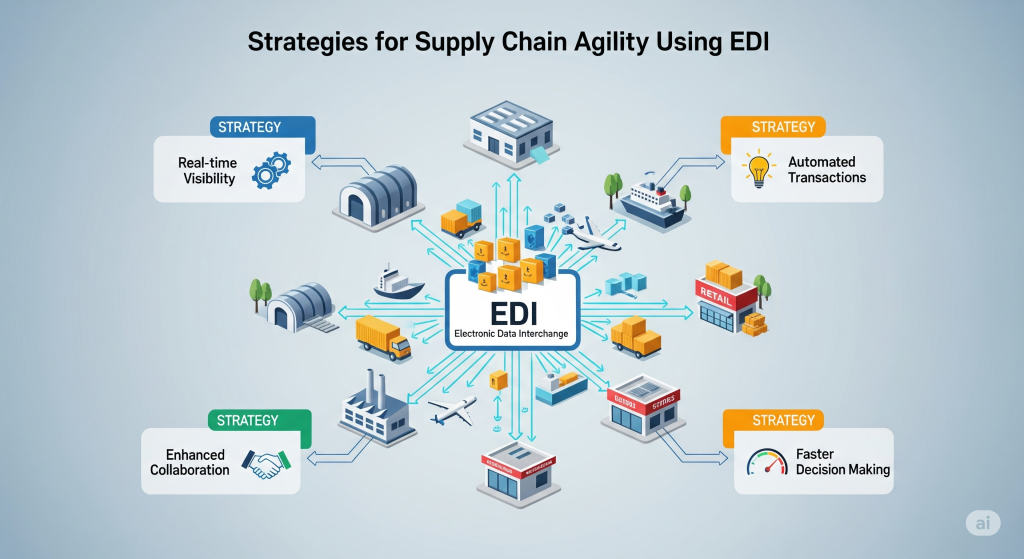

EDI in Supply Chain: Foundation of Digital Communication

Electronic Data Interchange (EDI) serves as the cornerstone of modern supply chain communication. This standardized format enables computer-to-computer exchange of business documents between different partners, eliminating manual processes that traditionally slowed down supply chains.

Common EDI Documents

The backbone of supply chain EDI transactions consists of four primary document types that facilitate seamless business operations:

- EDI 850 (Purchase Order): Initiates the buying process when a retailer or buyer sends a request for products, including quantities, billing details, and shipping instructions.

- EDI 810 (Invoice): Sent by suppliers after delivery, detailing products delivered and payment due, expediting payment processing by reducing paperwork.

- EDI 856 (Advance Shipping Notice/ASN): Provides detailed information about shipment contents and configuration before delivery, preparing recipients for incoming goods.

- EDI 846 (Inventory Inquiry/Advice): Enables suppliers to send inventory updates to partners, detailing current stock levels and product availability.

EDI Benefits

Implementing EDI in supply chain operations delivers substantial advantages. Primarily, EDI allows enterprises to cut processing time remarkably, speeding up business cycles by 50-60% compared to traditional order-to-shipment cycles.

Accuracy improvements are equally impressive. Automation significantly reduces human errors in data entry that often lead to miscommunications, incorrect shipments, and financial losses. In the UK alone, the grocery sector saves £650 million annually through EDI implementation.

Beyond these benefits, EDI creates a paperless environment, reducing costs associated with printing, filing, administration, and mailing—expenses that otherwise would be repeated for each transaction.

EDI integration

EDI-ERP integration enables data to flow between front-end EDI applications and back-end ERP systems automatically. This integration process involves:

- Receiving EDI documents (like an 850 purchase order)

- Converting transactions to internal formats (Idoc, XML, FF)

- Pushing information into the ERP using API connections

Similarly, WMS integration with EDI eliminates manual data entry, streamlining warehouse operations. As organizations send and receive hundreds of EDI documents monthly, automation becomes essential for growth.

EDI vs email/manual processes in logistics

The contrast between EDI and manual processes reveals why digitalization has become imperative:

| Process Area | Manual Processing | EDI Processing |

| Ordering | Orders emailed manually with typos/errors | Orders are sent automatically with improved accuracy |

| Confirmation | Email/phone updates requiring manual input | Status updates flow directly into systems |

| Shipping | Limited coordination and visibility | Advanced notices enable warehouse preparation |

| Invoicing | PDFs/hard copies requiring manual entry | Invoices are transmitted and validated automatically |

This automation reduces per-transaction time from days to minutes, dramatically increasing transaction volume without additional resources.

Understanding VAN: Secure Data Exchange Infrastructure

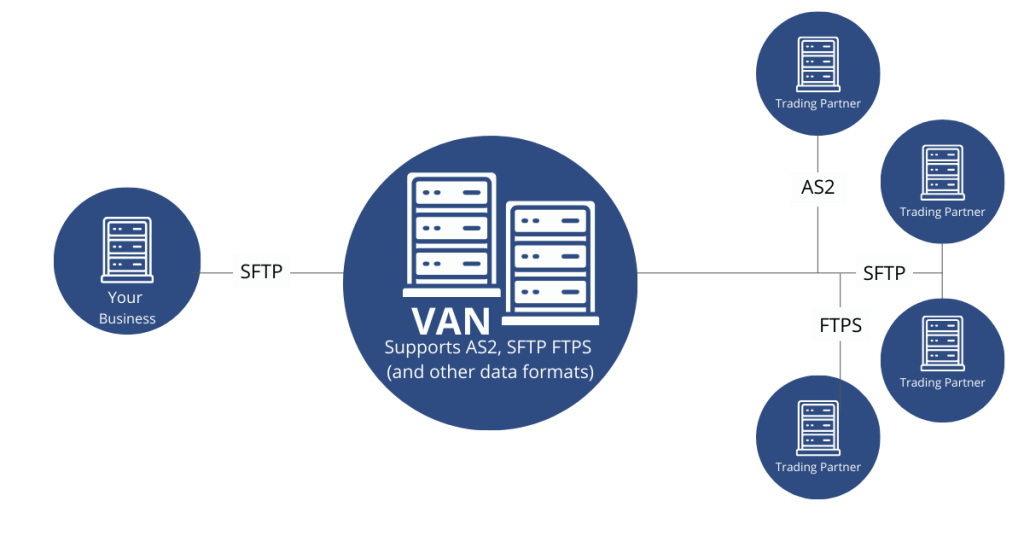

Value-Added Networks (VANs) function as secure digital highways in modern supply chain digitalization, enabling the reliable transmission of EDI documents between trading partners. As businesses seek improved efficiency in their supply chain operations, understanding the infrastructure that supports these communications becomes increasingly important.

What is a Value-Added Network (VAN)?

At its core, a VAN is a secure, private network that facilitates the exchange of electronic business documents like purchase orders and invoices in standardized formats. It operates as an intermediary between trading partners, processing and routing EDI messages through a virtual mailbox system. Companies connect to the VAN rather than directly to each other, allowing the network to receive, validate, store, and forward EDI transactions to appropriate recipients.

The mailbox model operates much like a digital post office. When you send an EDI document, it’s transmitted to the VAN, which subsequently stores it in your partner’s mailbox until retrieval. This mechanism ensures delivery even if the recipient’s system is temporarily offline or experiencing technical difficulties.

VAN vs point-to-point EDI architecture

Unlike point-to-point connections that require managing individual links with each trading partner, VANs offer a streamlined alternative:

Point-to-Point Architecture | VAN Architecture |

Requires separate connections to each partner | Single connection reaches multiple partners |

Complex to manage at scale | Simplified partner onboarding |

Limited protocol flexibility | Supports various protocols and formats |

Higher internal IT burden | Reduced technical complexity |

This centralized approach decreases the total number of stakeholders involved, primarily reducing business-to-business complexities.

Scalability and security benefits of VANs

VANs employ robust security measures that protect sensitive business data during transmission. These typically include encryption, password protection, cryptography, and data integrity checks. Generally, these networks provide comprehensive audit trails, tracking each document throughout its journey.

From a scalability perspective, VANs excel in accommodating growing businesses. As companies add trading partners, they avoid the complexity of establishing new direct connections—the VAN handles these logistics. Notably, this flexibility makes it easier for businesses to expand their trading network without significant infrastructure changes.

Cost considerations in VAN-based EDI

Despite their advantages, cost remains an important factor when evaluating VANs. Traditional providers often use complex pricing models, including:

- Monthly base fees tied to usage tiers

- Per-message or per-kilocharacter charges

- Mailbox and setup fees

- Onboarding or migration fees

In fact, companies working with modern VAN providers report saving 40-80% on annual costs by eliminating these unpredictable fees. Although VANs require ongoing subscription costs, many businesses find the investment worthwhile given the reduced need for internal infrastructure and technical expertise.

GDSN for Product Data Synchronization

The Global Data Synchronization Network (GDSN) stands as a critical pillar in the foundation of modern supply chain digitalization, ensuring product information remains accurate across all touchpoints in the value chain.

What is GDSN?

GDSN is an internet-based, interconnected network of interoperable data pools governed by GS1 standards that enables trading partners to share standardized product information. Functioning as a bridge between brands and merchants, GDSN facilitates the electronic transfer of standardized product data between trading partners and maintains continuous synchronization of that information over time. The network primarily handles product master data, including attributes such as weight, description, brand name, and Global Trade Item Number (GTIN), ensuring all partners have access to the same accurate information.

GDSN in Retail and CPG Supply Chains

In retail and consumer packaged goods (CPG) sectors, GDSN has profoundly altered the relationship between suppliers and retailers, bringing unprecedented efficiency and interconnectivity. The French retail giant Carrefour has leveraged GDSN across both B2B and B2C channels for 15 years, witnessing improvements across nearly every aspect of day-to-day business operations. Whenever a company changes product information, this data is automatically and immediately provided to downstream trading partners using the network.

Real-Time Product Updates and Compliance

Through GDSN, high-quality product content is uploaded, maintained, and shared automatically, ensuring trading partners have immediate access to current information needed for product exchange. The continuous flow of accurate and up-to-date information creates a single point of truth across the entire supply chain. Since the enactment of European Regulation 1169 in 2014, online food retailers must provide consumers with nutritional information before purchase, making GDSN compliance features increasingly valuable.

GDSN vs manual product data entry

Manual Data Entry | GDSN |

Time-consuming manual updates | Real-time synchronization |

Error-prone processes | 25% reduction in data errors |

Inconsistent data across channels | Single source of truth |

Limited scalability | Reaches multiple partners simultaneously |

Organizations implementing GDSN report a 30% increase in operational efficiency, remarkably improving their ability to bring new products to market quickly.

PIM Tools for Centralized Product Information Management

As supply chains become increasingly complex, Product Information Management (PIM) systems emerge as vital tools for centralizing and optimizing product data throughout digital commerce networks.

What is a PIM System?

PIM systems function as centralized repositories that collect, manage, and enrich product information from various sources, creating a single source of truth for all product-related data. Primarily designed to streamline product information flows, these platforms eliminate manual processes while enabling consistent data distribution across multiple sales channels.

PIM vs GDSN: Complementary Roles

Whereas GDSN focuses on standardized data exchange between trading partners, PIM concentrates on internal data management and enrichment. The two systems work together effectively. PIM manages the centralized product information that ultimately feeds into GDSN for broader distribution. This partnership allows companies to maintain detailed, customized product data internally while sharing standardized information with external partners.

Improving Product Data Quality and Consistency

Research indicates that 87% of shoppers claim accurate product content directly influences their purchasing decisions. Through effective implementation of PIM, companies create consistent, accurate product experiences across all touchpoints. These systems validate data quality, standardize formats, and maintain comprehensive audit trails.

PIM Integration with e-commerce and ERP Platforms

PIM integration connects product information with adjacent systems like ERP, CRM, and e-commerce platforms. This unified architecture allows upstream systems to feed structured data into PIM while downstream channels utilize enriched content, creating an efficient flow from source to sale.

Integrating EDI, VAN, GDSN, and PIM for End-to-End Visibility

Integration of EDI, VAN, GDSN, and PIM forms the backbone of true end-to-end visibility in modern supply chains. Rather than functioning independently, these technologies create a cohesive framework that enhances operational efficiency throughout the entire supply network.

Unified Architecture for Digital Supply Chains

A unified architecture transforms fragmented operations into an intelligent ecosystem supporting digital transformation and business process management. Looking beyond siloed optimizations, companies now strive for visibility across the entire supply chain. This comprehensive approach enables businesses to be more responsive when disruptions occur, tracking how changes ripple throughout the network.

Data flow between EDI, VAN, GDSN, and PIM

The data flow between these systems follows a structured process:

- Data extraction and centralization in PIM

- Data cleansing and enrichment

- Registration and publication to GDSN

- Subscription and synchronization by trading partners

- Transaction automation through EDI

This integration eliminates data silos that typically plague supply chains. With proper tools, the entire process becomes seamless, reducing manual intervention.

Challenges in Multi-System Integration

Data silos remain a significant barrier, occurring when information is stored separately with limited sharing. Primarily, these isolation points stem from incompatible software or departmental boundaries. Furthermore, integration complexity presents another obstacle—many EDI formats weren’t designed for human readability, making error detection challenging.

Best practices for seamless interoperability

For effective interoperability, organizations should:

- Implement unified data platforms consolidating information from various sources

- Adopt cloud-based solutions offering real-time synchronization

- Invest in data integration tools with robust API connections

Conclusion

The true power of supply chain digitalization emerges when these four technologies (EDI, VAN, GDSN, and PIM) work together. This unified architecture eliminates data silos, enables end-to-end visibility, and creates an intelligent ecosystem responsive to disruptions. Companies embracing this integrated approach will undoubtedly gain competitive advantages through faster processes, reduced costs, and enhanced customer experiences.

As we look to the future, supply chain professionals must understand these foundational technologies not as separate tools but as complementary components of a comprehensive digitalization strategy. After all, mastering the integration of EDI, VAN, GDSN, and PIM doesn’t just transform operations it fundamentally reimagines how supply chains function in our increasingly digital world.

Commport Solutions for Supply Chain Industry

Frequently Asked Questions

Supply chain digitalization is the transformation of traditional supply chains into interconnected, intelligent networks using digital technologies. It’s crucial because it enhances speed, accuracy, and automation in supply chain operations, leading to cost savings, improved efficiency, and better responsiveness to market changes.

EDI (Electronic Data Interchange) automates document exchange between trading partners, reducing operational expenses by up to 35% and accelerating business cycles by 50-60%. It improves accuracy, speeds up transactions, and eliminates manual data entry errors, making supply chain communication more efficient and cost-effective.

VANs serve as secure digital highways for EDI document transmission. They simplify partner connectivity by allowing businesses to reach multiple trading partners through a single, secure connection. This reduces technical complexity, improves scalability, and can lead to 40-80% savings on annual costs compared to managing individual connections.

GDSN ensures that product information remains accurate and consistent across all touchpoints in the supply chain. It creates a single source of truth for product data, enabling real-time synchronization between trading partners. This reduces data errors by 25% and increases operational efficiency by 30%, particularly benefiting retail and CPG supply chains.

Integrating these technologies creates a unified architecture that enables end-to-end visibility in the supply chain. This integration eliminates data silos, streamlines information flow, and creates an intelligent ecosystem that can quickly respond to disruptions. It allows businesses to track changes across the entire network, leading to more efficient operations and better decision-making capabilities.