Introduction

EDI for suppliers has become the digital backbone of global supply chains, transforming how companies exchange critical business documents.

Thousands of suppliers find themselves in this exact situation every year – retailers issue millions of orders daily that humans simply can’t keep up with. What’s more concerning? Every EDI message must be perfectly structured without typos or missing fields, or you’ll face fines.

Essentially, Electronic Data Interchange (EDI) allows machines to communicate rapidly, automating the exchange of business documents like purchase orders, invoices, and shipping forms between organizations. This automation enables near real-time processing of transactions, drastically reducing the time from order to delivery.

We understand that implementing an EDI system can feel overwhelming at first. However, retailers don’t use EDI because it’s fancy – they use it because without it, their system breaks. In this comprehensive guide, we’ll walk you through everything you need to know as a supplier about how to become EDI compliant and retail-ready, from understanding the basics to choosing the right EDI solution.

Key Takeaways

- EDI compliance is mandatory, not optional– Major retailers require suppliers to exchange standardized electronic documents or face costly chargebacks up to 5% of revenue.

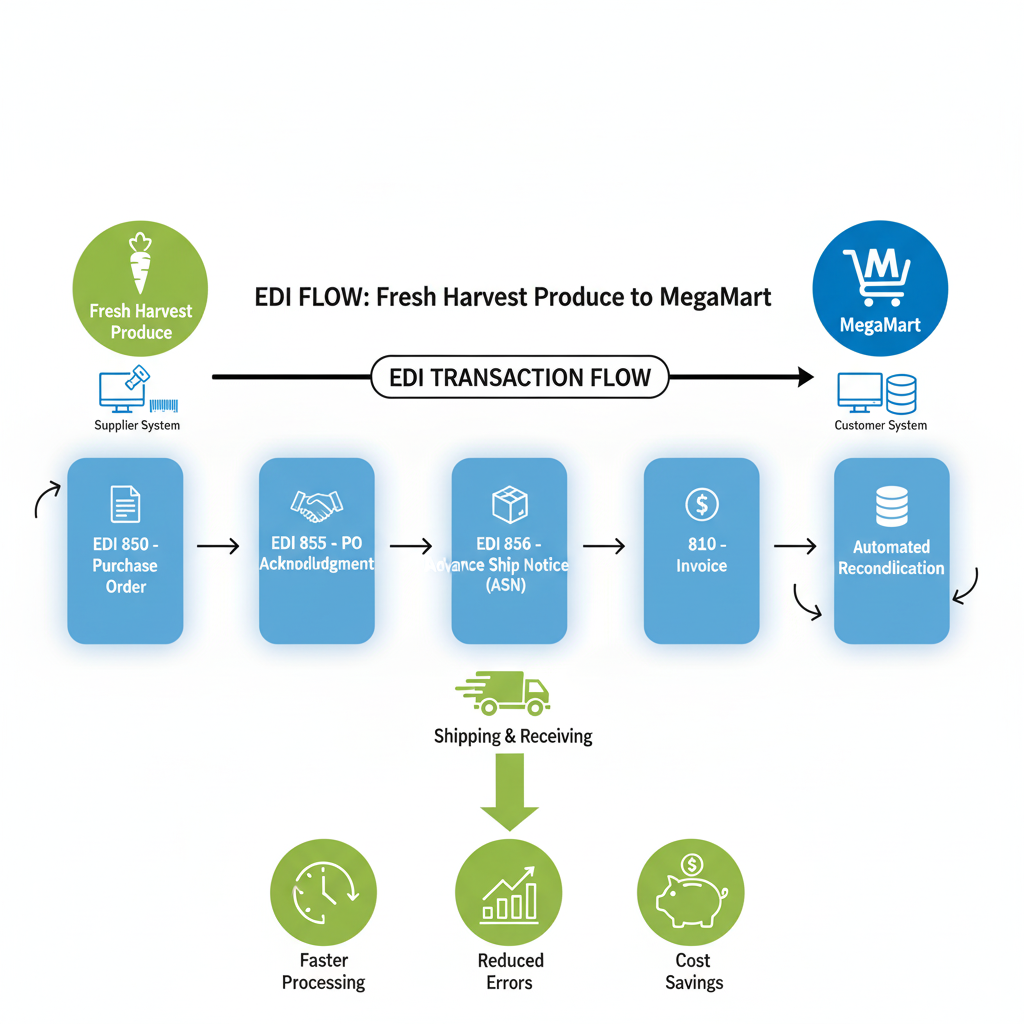

- Master four core documents first– Focus on EDI 850 (purchase orders), 856 (shipping notices), 810 (invoices), and 997 (acknowledgments) for retail readiness.

- Integration with ERP/WMS is critical– Seamless system integration eliminates manual data entry, reduces errors by 90%, and accelerates order processing from days to minutes.

- Choose managed EDI over in-house for faster results– Managed services offer lower startup costs, faster implementation, and expert support without hiring specialized staff.

- Treat EDI as an ongoing process, not a one-time setup– Continuous monitoring, regular testing, and cross-functional team involvement prevent costly failures and ensure long-term success.

What Is EDI and How It Helps Suppliers

In the supply chain world, Electronic Data Interchange (EDI) stands as the first truly disruptive digital technology that fundamentally changed how businesses communicate. Let me walk you through what EDI means for suppliers and why it’s become indispensable in modern business operations.

Definition and Purpose of EDI

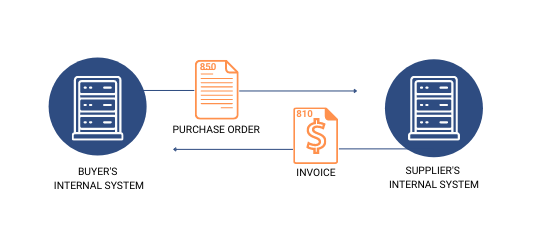

Electronic Data Interchange represents the computer-to-computer exchange of business documents in standardized electronic formats between trading partners.

Originally developed in the 1960s, this technology has evolved into a cornerstone of efficient supply chain management.

The core purpose of EDI is remarkably straightforward – it replaces traditional paper-based transactions with electronic ones that follow standardized formats. This standardization is crucial as it ensures compatibility between different business systems, allowing companies to communicate without confusion regardless of their internal processes.

When suppliers implement EDI, they gain the ability to transmit critical business information directly from their system to their partners’ systems without human intervention. The entire process can take minutes or hours compared to days or weeks for paper-based equivalents. Additionally, EDI transactions happen automatically—flowing from suppliers’ accounts receivable systems to buyers’ accounts payable systems almost instantly.

How EDI Replaces Manual Data Handling

The contrast between manual processes and EDI is striking. In a manual environment, processing purchase orders and invoices consumes significant time and introduces numerous opportunities for errors. For instance, a buyer might send a purchase order to a supplier who then needs to translate that data into something compatible with their in-house system.

Through automation, EDI eliminates these tedious processes. When suppliers receive an EDI purchase order, it automatically enters their order management system without requiring any manual data entry. This automation speeds up transaction processing, reducing errors caused by human input while improving overall operational efficiency.

Let’s examine the differences:

- Manual process: Involves paper documents, human data entry, email attachments, and inevitable delays

- EDI process: Fully automated — no paper, no people, much faster results

By switching to EDI, suppliers can reduce order processing times by up to 50%. Furthermore, the accuracy improvements are substantial since EDI minimizes the risk of errors associated with manual data entry, leading to fewer discrepancies in orders, shipments, and payments.

EDI in E-commerce and Manufacturing

For online retailers and their suppliers, EDI helps automate order processing, manage inventory, and track shipments in real-time, resulting in faster order fulfillment, fewer shipping errors, and seamless integration with warehouse management systems.

I’ve seen firsthand how EDI allows e-commerce suppliers to:

- Automatically place orders with their suppliers when stock levels get low

- Submit compliance documents to retail partners

- Make adjustments according to real-time inventory changes

- Simplify onboarding processes for new partners

Meanwhile, in manufacturing, EDI streamlines the entire supply chain from procurement to production. The first processes that EDI solutions addressed were the order-to-cash and procure-to-pay cycles. This automation enables manufacturers to maximize efficiency throughout all processes of supply chain management, improving both inventory management and business operations.

For suppliers working with major retailers or manufacturers, EDI isn’t optional – it’s often a mandatory requirement for doing business. Without it, suppliers risk order rejection, delays, or financial penalties.

Electronic Data Interchange ultimately helps suppliers stay competitive by enabling faster transactions, reducing costly errors, lowering operational expenses, building stronger partnerships, and providing the scalability needed to handle increased order volumes without adding staff.

Types of EDI Systems For Suppliers and How They Work

Navigating the technical landscape of EDI can be confusing for suppliers new to electronic trading. Understanding the different types of EDI systems is crucial before implementing one for your business.

What is an EDI system?

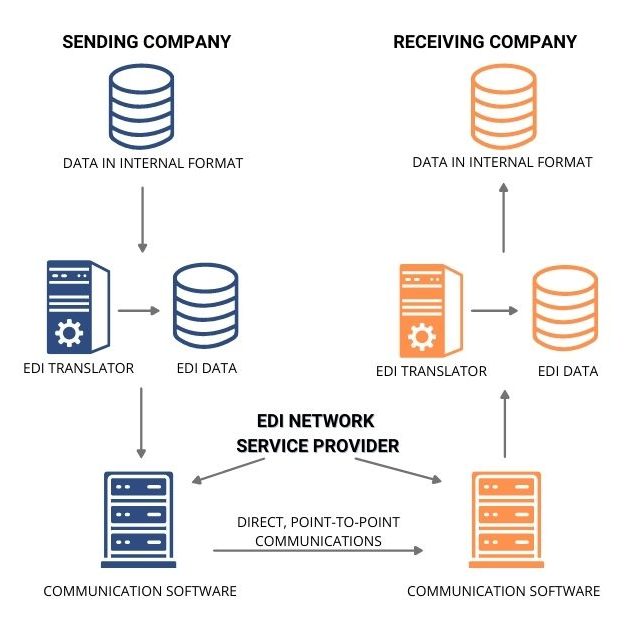

An EDI system is fundamentally the software and infrastructure that enables the electronic exchange of business documents between trading partners using standardized formats. Unlike manual processes that rely on paper documents or emails with attachments, EDI systems automate document exchange without human intervention.

These systems handle several key functions:

- Translating your internal data formats into standardized EDI formats

- Securing document transmission between partners

- Validating that documents meet required standards

- Tracking and confirming successful document delivery

The core purpose of an EDI system is to establish a reliable digital pathway for business communication, primarily focusing on critical supply chain documents like purchase orders, invoices, and shipping notices.

Direct vs indirect integration

When implementing EDI for suppliers, you’ll face a fundamental choice between direct and indirect integration approaches.

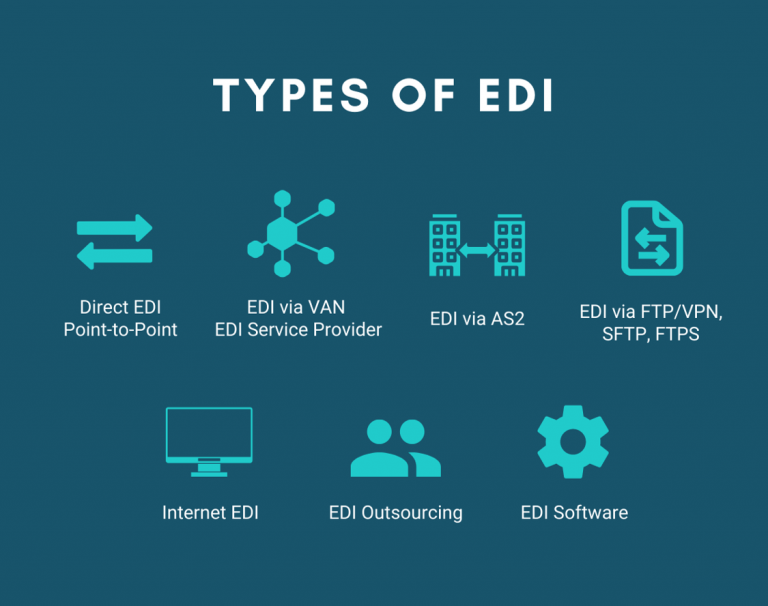

Direct EDI integration (also called point-to-point) creates specific connections directly between your system and each trading partner’s system. This approach uses protocols like AS2 or FTP to establish a dedicated connection from your trading partners straight to your internal ERP. Direct integration gives you complete control and ownership of your EDI operations, making it particularly suitable for larger-scale integrations that move substantial data volumes between your ERP and trading partners.

Indirect EDI integration utilizes a third-party Value-Added Network (VAN) or broker that acts as an intermediary between your systems and your trading partners. The VAN receives messages from your ERP, transforms them to the necessary format, and then forwards them to your trading partners. This approach simplifies partner onboarding as the VAN handles network connectivity and translation software setup.

Many organizations opt for a hybrid EDI integration approach, combining both direct and indirect methods. For instance, they might use a VAN to handle most EDI transmissions but maintain direct EDI connections with critical customers.

EDI Communication Protocols

EDI protocols are essentially the “languages” that determine how data is transmitted, authenticated, and secured during the exchange process. For successful EDI communication, trading partners must either use the same protocol or employ a VAN that can translate between different protocols.

The most common EDI transmission protocols include:

AS2 (Applicability Statement 2) – Developed specifically for B2B document exchange, AS2 became extremely popular after Walmart required all suppliers to use it. It provides real-time transaction processing, enhanced security through encryption and digital signatures, and receipt confirmations via Message Disposition Notifications (MDNs).

SFTP/FTPS – These secure versions of the traditional File Transfer Protocol offer enhanced security for file transfers, though they lack automatic receipt confirmations.

OFTP2 – Particularly popular in the European automotive industry, OFTP2 allows both pushing and pulling information (unlike AS2, which only pushes). It offers high data compression capabilities and sophisticated security features.

HTTP/HTTPS – While basic HTTP offers limited security, HTTPS with TLS (Transport Layer Security) provides a more secure option for web-based EDI exchanges.

In recent years, API-based integration has emerged as a complementary approach to traditional EDI protocols. Though APIs offer instant data access without requiring partner availability at transmission time, they lack the standardization of established EDI protocols, potentially creating complexity when managing multiple trading relationships.

Your choice of EDI system and protocol should align with your business needs, technical capabilities, and trading partner requirements. Most retailers will specify which EDI documents and protocols you must support, often requiring testing and certification before you can begin trading electronically.

Key Documents Every EDI Supplier Must Handle

Mastering the core EDI documents stands as a fundamental requirement for suppliers aiming to establish successful electronic trading relationships. Most retailers and distributors require suppliers to process four critical EDI transaction sets. Let’s explore these essential documents that form the backbone of EDI for suppliers.

EDI Purchase Order (850)

The EDI 850 Purchase Order represents one of the most frequently used EDI document types in the supplier ecosystem. As an electronic purchase order, it initiates the ordering process from buyers to suppliers, effectively eliminating manual input errors and accelerating procurement.

This digital document contains vital information identical to traditional paper purchase orders:

- PO number and order date

- Item descriptions, quantities, and pricing

- Requested shipping and delivery dates

- Payment terms and shipping details

- Product identifiers (SKUs, UPCs)

The EDI 850 flows directly into your order management system once received. Notably, without EDI integration, staff would need to periodically check for new orders and manually re-key them into your ERP system for fulfillment. This automated approach streamlines operations, consequently allowing both buyers and sellers to optimize business processes.

Upon receiving an EDI 850, suppliers typically respond with a functional acknowledgment (EDI 997) to confirm receipt, subsequently followed by other documents as the order progresses through fulfillment.

Advance Ship Notice (856)

The EDI 856 Advance Shipping Notice (ASN) serves as a critical pre-shipment notification document. Sent after order processing but before delivery, this document informs buyers about upcoming shipments, enabling them to plan accordingly.

An effective advanced shipping notice (ASN) must include:

- Shipment number and shipping date

- Expected delivery timeline

- Purchase order reference

- Item details and quantities

- Packaging information (which items in which cartons)

- Tracking details and carrier information

- UCC128/GS1 numbers for cartons or pallets

For retailers, the ASN helps track inbound inventory and plan labor based on upcoming deliveries. Indeed, most major retailers mandate ASNs within specific timeframes before product arrival at their distribution centers or stores.

For suppliers, implementing the EDI 856 creates numerous benefits including faster order-to-payment cycles, improved shipment tracking, and strengthened retailer relationships through reduced errors and missed deliveries.

Invoice (810)

The EDI 810 Invoice functions as the electronic equivalent of a paper billing document, sent by suppliers to request payment for delivered goods or services. This transaction set typically follows the shipment of ordered products.

Key components of the EDI 810 include:

- Invoice number and date

- PO reference numbers

- Item details with quantities and pricing

- Payment terms

- Shipping information

Integrating both invoices and purchase orders helps automate the purchase order-to-invoice reconciliation process, reducing payment cycles and administrative workload. Furthermore, the electronic nature of EDI 810 minimizes errors and discrepancies that commonly occur with manual billing processes.

Functional Acknowledgment (997)

The EDI 997 Functional Acknowledgment represents a critical yet often underappreciated component of EDI communications. Unlike other transaction sets that carry business data, the 997 serves as a technical receipt confirming an EDI transmission was received and processed correctly.

This transaction verifies:

- Receipt of the EDI document

- Compliance with EDI standards

- Successful initial processing

- Syntactical correctness of the data

Important to realize: receiving a 997 acknowledgment only confirms technical receipt and processing—not acceptance of the business content. The document typically contains the received transaction code and notification of whether the transaction was accepted, rejected, or contained errors.

Proper implementation of automated 997 acknowledgments creates closed-loop communication systems that enhance reliability and provide clear audit trails. According to EDI integration specialists, this reduces communication-related errors by up to 90%, dramatically improving overall EDI operations.

Mastering these four core EDI documents enables suppliers to efficiently manage the entire order-to-cash cycle electronically, meeting retailer requirements while streamlining internal operations.

How Suppliers Can Become EDI Compliant with Retailers

For suppliers seeking to do business with major retailers, EDI compliance isn’t optional—it’s mandatory. Retailers rely on EDI to streamline their massive supply chains, processing millions of transactions daily that would overwhelm manual systems.

1. Understanding Retailer Mandates

Retailer EDI mandates require suppliers to exchange business documents electronically following strict specifications unique to each trading partner. These mandates typically specify:

- Which EDI transaction sets you must support (commonly 810, 850, 855, 856, 860, and 997)

- Transmission methods and protocols (such as AS2 for Walmart)

- Timing requirements for document exchanges

- Data formatting and field requirements

Major retailers like Walmart and Amazon maintain detailed implementation guides outlining their specific EDI requirements. For instance, Walmart mandates that all EDI traffic flow through AS2 with SHA-256 signed certificates, along with proper handling of Message Disposition Notifications (MDNs) as digital receipts.

Moreover, retailers periodically update their guidelines to ensure compliance with current standards, requiring suppliers to adapt quickly to these changes.

2. Testing and Certification Process

Becoming EDI compliant involves a structured testing and certification process before you can begin live transactions. This critical phase verifies that your systems can correctly exchange data according to retailer specifications.

The typical certification process includes:

- Collecting trading partner requirements and guidelines

- Configuring your EDI system to meet those specifications

- Mapping your internal data formats to required EDI structures

- Conducting validation testing with sample documents

- Completing end-to-end testing with your trading partner

Many retailers require suppliers to complete EDI testing within specific timeframes—for example, Walmart expects the basic document set testing to be completed within six weeks. Passing certification confirms that your EDI documents match the retailer’s exact specifications and that your AS2 or other connection methods function correctly.

Given the complexity of this process, many suppliers opt for a managed EDI solution to handle certification. Commport EDI solutions will help you become EDI compliant with all trading partners. Trusted by 6000+ brands. 40+ years of industry experience have made the EDI onboarding process significantly easier for suppliers who lack in-house EDI expertise.

3. Avoiding Chargebacks and Delays

Non-compliance with retailer EDI requirements leads to costly chargebacks—financial penalties imposed when suppliers fail to meet specific operational requirements. According to industry estimates, these chargebacks can cost suppliers anywhere from 1% to 5% of gross annual revenue. For a company with $10 million in sales, that translates to potential losses of up to $500,000 annually.

Common chargeback triggers include:

- Missing or incorrect Advanced Shipping Notices (ASNs)

- Late, early, or partial shipments

- Incorrect invoice details or pricing mismatches

- Poor barcode or label compliance

- Failure to meet EDI guidelines set by the retailer

In reality, the best defense against chargebacks is prevention through proper EDI implementation. Automating EDI transactions significantly reduces errors by eliminating manual data entry points. An integrated EDI solution runs built-in checks for missing fields, mismatched quantities, or incorrect pricing—catching issues before documents reach your retail partners.

For this reason, maintaining EDI compliance isn’t a one-time achievement but an ongoing process. Retailers expect suppliers to monitor message flows continuously, renew certificates before expiration, and adapt to guideline changes promptly.

Integrating EDI with Your ERP or WMS

Successful EDI implementation extends beyond simply meeting retailer requirements—it requires seamless integration with your existing business systems. Connecting your EDI solution directly with your Enterprise Resource Planning (ERP) or Warehouse Management System (WMS) transforms what could be a compliance burden into a strategic advantage for your supply chain operations.

Why Integration Matters

First and foremost, EDI-ERP integration eliminates the inefficiencies of manual processes. Without integration, staff must download EDI messages, manually interpret them, and re-key that information into your business systems—creating bottlenecks and introducing error risks. Automating this data flow between systems removes the need for manual re-keying and drastically reduces the possibility of user error.

The benefits of proper integration are substantial:

- Improved data accuracy: Automated EDI ingestion and transformation into your ERP eliminates manual data entry errors. Even if only 1% of orders are entered incorrectly, those mistakes create significant headaches throughout your organization.

- Accelerated business cycles: An integrated system can reduce processing times from days to minutes, enabling your business to complete transaction cycles substantially faster.

- Enhanced supply chain visibility: With accurate, automated data flowing between systems, you gain comprehensive insight into trading partner activities, allowing you to focus on business growth rather than chasing missed orders or troubleshooting failed transmissions.

Nevertheless, many organizations still treat EDI as a separate function rather than an integrated component of their business processes. This siloed approach limits the potential benefits and creates unnecessary complexity.

Common ERP Platforms Used by Suppliers

Popular ERP systems used by suppliers include:

- NetSuite ERP: Cloud-based solution with strong multi-channel capabilities

- SAP S/4HANA: Enterprise-level architecture that scales effectively across teams and regions

- Microsoft Dynamics 365: Offers built-in integration with various business applications

- Epicor Kinetic: Industry-specific functionality for manufacturing and distribution

- Oracle Fusion Cloud ERP: Comprehensive enterprise solution with advanced supply chain features

When selecting an ERP system, consider its native EDI capabilities, available connectors, and flexibility to handle your specific trading partner requirements. Despite this, most ERPs don’t have comprehensive “out of the box” EDI connectors available or the expertise to build custom integrations beyond basic EDI-to-ERP connections.

Mapping EDI to Internal Workflows

EDI mapping serves as the technical foundation for successful integration. This process involves translating data between different formats—enabling your internal systems to understand incoming EDI documents and properly format outgoing ones.

During EDI-to-ERP mapping, data structures are translated from standardized EDI formats (like EDIFACT or ANSI X12) into proprietary files that your back-end system can process (CSV, TXT, or other ERP-specific formats).

Effective mapping requires:

- Source document analysis: Thoroughly examining source documents to understand their structure

- Target format identification: Understanding your ERP’s required document structure

- Mapping rule creation: Defining clear rules aligning source data elements with target formats

- Validation and error handling: Building processes to validate transformed data and address errors

Creating consistently effective maps requires adopting best practices like using clear naming conventions, providing thorough documentation, and extensive testing with various data scenarios.

As a result of proper integration, your EDI system becomes more than just a compliance tool—it transforms into a strategic solution that improves efficiency, reduces costs, and strengthens relationships with trading partners.

In fact, manufacturers who properly integrate EDI with their ERP can reduce manual order entry by up to 90%, eliminating fulfillment errors and enabling faster transactions with suppliers.

Choosing an EDI Vendor or Managed Service

Selecting the right EDI solution marks a critical decision point for suppliers – one that can either streamline operations or create ongoing challenges. Your choice of EDI vendor or service model directly impacts your ability to meet retail requirements efficiently.

What to Look for in an EDI Provider?

Initially, evaluate the provider’s platform capabilities. An effective EDI solution should support any data standard or format while complying with various communication protocols. The system should seamlessly integrate with your enterprise systems, whether ERP, WMS, CRM, or e-commerce platforms.

Industry experience and pre-established connections prove equally important. Look for providers with expertise in your specific business sector and existing relationships with your trading partners. Commport EDI for Suppliers offers affordable and scalable EDI solutions with easy integration to all major ERPs and other backend office systems. With 40+ years of industry experience and trusted by 6000+ brands, they help suppliers become EDI compliant with all trading partners.

Beyond basic functionality, consider complementary service offerings that augment the EDI platform, including onboarding services, collaborative portals, and API management. First-rate providers also demonstrate ongoing investment and innovation in their platform, incorporating technologies like artificial intelligence and advanced APIs to improve supply chain processes.

Pros and Cons of Managed vs In-house

In-house EDI management typically appeals to organizations with specific characteristics:

- Desire for complete control over data and processes

- Available skilled personnel to manage the system

- Need for immediate support and agility when issues arise

Alternatively, managed EDI services offer distinct advantages:

- Lower startup costs with consistent monthly budgeting

- Faster implementation timeframes

- Access to expertise without hiring specialized staff

- Less maintenance and knowledge transfer concerns

The primary downsides of in-house management include higher initial costs, staffing challenges, and slower implementation. In contrast, managed services provide less customization flexibility and may lack multi-year cost benefits.

Questions to Ask Before Signing

Before committing to any EDI provider, ask these critical questions:

- What are your service level agreements regarding uptime and support response times?

- How do you handle trading partner onboarding and testing? The provider should have streamlined processes for bringing new partners online efficiently.

- What security measures and certifications do you maintain?

- Can you provide references from clients in my industry? A quality provider will share testimonials from businesses similar to yours.

- How will you support our growth as transaction volumes increase? The solution should scale alongside your business without significant additional investment.

- Understand all costs, including setup fees, monthly charges, and any per-transaction cost,s before making your final decision.

Common Mistakes and How to Avoid Them

Even the best-planned EDI implementations can falter when suppliers overlook critical operational aspects. Understanding these common pitfalls can save your business from costly mistakes and disruptions in your supply chain relationships.

1. Treating EDI as a One-Time Setup

Many organizations make the mistake of viewing EDI as a “set-it-and-forget-it” solution. In reality, EDI is not merely a one-time connection—it’s an ongoing process requiring continuous attention. This flawed perspective can introduce serious issues as your business evolves.

Without planning for long-term updates, suppliers risk facing:

- Compatibility issues with new trading partner requirements

- Costly manual workarounds for exceptions

- Increased expenses when onboarding new partners

The most successful organizations recognize EDI as a dynamic component of their operations, not a background utility. They implement strategic approaches that prioritize ongoing visibility, regular testing, and consistent partner support—setting the foundation for sustainable business growth.

2. Assigning EDI to the Wrong Team

A fundamental error many companies make is treating EDI solely as an IT project. Although technical teams excel at system connectivity, they often lack insight into how data flows affect daily business operations.

This disconnect creates a dangerous gap—IT implements solutions that work technically but fail to align with actual business processes. For instance, IT might designate “delivery date” as a single field, while shipping departments use three distinct timestamps (promised, estimated, and actual). Such misalignments lead to production timing issues, missed shipping dates, and ultimately ASN failures.

To overcome this challenge, form cross-functional implementation teams including end users from purchasing, logistics, finance, and customer service. Give these departments genuine decision-making authority during design reviews to ensure EDI mappings reflect real-life business practices.

3. Ignoring Daily Monitoring

Perhaps the most destructive mistake is failing to monitor EDI operations consistently. Without clear visibility into your EDI system, minor issues quickly escalate into expensive problems. Delayed transactions, failed document exchanges, and misrouted data often go undetected without proper alerting tools.

Proactive monitoring prevents errors instead of merely reacting to them. Regular analysis of EDI reports identifies patterns in issues and informs corrective measures. Furthermore, consistent review of transactions prevents unaddressed problems and delayed reimbursements.

Modern EDI platforms offer real-time observability features that reveal issues as they happen, dramatically improving overall operations. When suppliers can identify and resolve problems immediately, they eliminate the surprise of hearing about errors from trading partners days later.

Future-Proofing Your EDI Operations

As global supply chains evolve rapidly, forward-thinking suppliers must prepare their EDI operations for future growth and technological changes. The electronic data interchange market continues expanding, projected to reach USD 49.21 billion by 2027, demonstrating its lasting importance in business communications.

1. Scaling to New Partners and Regions

Adaptable EDI infrastructure provides the foundation for business expansion. Whenever you’re entering new markets, adding trading partners, or experiencing transaction volume surges, scalable EDI solutions accommodate these changes without requiring complete system overhauls. Cloud-based EDI platforms enable even small businesses to participate in global supply chains, with tools for streamlined partner onboarding and support for specific EDI requirements across different regions.

2. EDI vs API: When to Use Both

Contrary to popular belief, APIs aren’t replacing EDI—they’re complementing it. Most modern supply chains benefit from leveraging both technologies strategically:

- Use APIs for real-time operations requiring instant data access: inventory lookups, price checks, and catalog information

- Rely on EDI for standardized business documents: purchase orders, invoices, and shipping notices

- Implement hybrid solutions when processing requires both technologies: initial API price checks followed by EDI order processing

Whoever can most quickly adapt to each communication requirement—whether EDI, non-EDI, or API—will separate themselves and earn new business.

3. Using EDI Data for Forecasting and Planning

Beyond basic transaction processing, EDI data provides valuable insights for strategic planning. By analyzing EDI transaction patterns, suppliers can detect seasonal shifts and product lifecycles, enabling more precise demand forecasting. Furthermore, EDI inventory management collects real-time sales data, offering better visibility into customer demand fluctuations.

Integrating EDI with business intelligence tools transforms inventory management from reactive to predictive. Suppliers who leverage this data gain a competitive advantage through optimized stock levels, preventing both shortages and excess inventory while improving overall supply chain efficiency.

Conclusion

Electronic Data Interchange has transformed from a retail requirement into a critical business advantage for suppliers worldwide. Throughout this guide, we’ve explored how EDI eliminates manual processes, reduces errors, and streamlines operations across the entire supply chain.

Undoubtedly, becoming EDI-compliant demands careful planning and execution. The journey starts with understanding the fundamental EDI documents—purchase orders, advance shipping notices, invoices, and acknowledgments—that form the backbone of electronic trading. Your success depends on selecting the right integration approach, whether direct connections or VAN services, based on your specific business needs.

Retailers expect flawless EDI implementation, not because they enjoy complex requirements, but because their operations literally depend on it. Failed or incorrect EDI transmissions result in costly chargebacks that can quickly erode profit margins. Therefore, proper integration with your existing ERP or WMS proves essential for maximizing benefits while minimizing these risks.

Selecting the right EDI partner stands as perhaps your most critical decision. The ideal solution offers scalability, security, and support tailored to your industry—enabling both compliance today and growth tomorrow. Additionally, avoiding common pitfalls requires treating EDI as an ongoing business process rather than a one-time IT project.

Most importantly, remember that EDI continues evolving alongside supply chain technologies. The future belongs to suppliers who combine traditional EDI with newer API capabilities, extract valuable data insights, and adapt quickly to changing requirements. This adaptability positions you not just as compliant but as a preferred trading partner.

We’ve witnessed countless suppliers transform their operations through proper EDI implementation. The initial learning curve might seem steep, but the rewards—faster order processing, fewer errors, lower operational costs, and stronger retailer relationships—make the investment worthwhile. EDI might start as a requirement, but it quickly becomes your competitive advantage in today’s digital supply chain.

Commport EDI Solutions - #1 EDI Solutions Platform

Need Help? Download: Commport's EDI Buyers Guide

Unlock the full potential of your supply chain with our comprehensive EDI Buyer's Guide — your first step towards seamless, efficient, and error-free transactions

Frequently Asked Questions

Setting up EDI for suppliers involves developing an organizational structure, conducting strategic reviews and in-depth analysis, selecting an EDI network provider, and integrating EDI with existing business systems. It’s a structured process that requires careful planning and implementation.

EDI streamlines operations for suppliers by automating document exchange, reducing manual data entry errors, speeding up order processing, and improving overall supply chain efficiency. It enables faster transactions, better inventory management, and stronger relationships with retail partners.

The three primary types of EDI systems are Direct EDI (point-to-point connections between trading partners), Value-Added Networks (VANs) that act as intermediaries, and Web-based EDI (also known as Internet EDI). Each type has its own advantages and is suitable for different business needs.

The cost of implementing EDI can vary widely depending on the complexity of the system. Basic setups may cost a few hundred dollars annually, while advanced systems connecting multiple trading partners can range into several thousand dollars per year. It’s important to calculate costs carefully to ensure a positive return on investment.

Suppliers typically need to master four core EDI documents: the 850 (Purchase Order), 856 (Advance Ship Notice), 810 (Invoice), and 997 (Functional Acknowledgment). These documents form the backbone of electronic trading with retailers and are crucial for becoming EDI compliant.