Introduction

With more than four trillion consumer products made, shipped, and sold globally every year, connected supply chain systems have become essential for businesses to manage this overwhelming complexity. We face a stark reality: according to MIT research, 81% of companies lack full visibility of their supply chains, while 54% admit having none at all.

This visibility gap explains why smart supply chain solutions are rapidly evolving. A McKinsey survey revealed that companies with end-to-end supply chain connectivity were twice as likely to report no challenges from recent disruptions. Supply chain connectivity isn’t just a competitive advantage anymore—it’s a necessity. Whether we’re discussing connected logistics for real-time tracking or comprehensive supply chain connectivity frameworks, the fundamentals remain the same.

Throughout this blog, we’ll explore the connected supply chain definition, examine the technologies driving this transformation, and reveal how businesses can prepare for the increasingly complex supply landscape of 2025.

What is a Connected Supply Chain?

In today’s globalized economy, supply chains play a crucial role in ensuring the efficient movement of goods from manufacturers to end consumers. Traditional supply chain models, however, face significant challenges such as fragmentation, inefficiencies, and lack of real-time visibility.

Definition and Key Components

A connected supply chain is a means of connecting everyone involved in the supply chain, drawing together disparate systems and partner networks to ensure information flows end-to-end whenever and wherever needed.

It aims to achieve 100% visibility in real-time, creating an integrated view across the company that encompasses suppliers, manufacturers, logistics partners, and customers.

The connected supply chain isn’t just about visibility and integration—it’s about creating a single, defined system where all parts communicate, share data and insights, and provide business benefits to everyone involved.

This complex network includes:

- Suppliers and manufacturers

- Distributors and retailers

- Logistics and service providers

- Technology and financial institutions

- Regulatory authorities

Core technologies enabling this connectivity include IoT for real-time tracking, AI/ML for predictive insights, cloud platforms for data integration, and blockchain for transparency and security.

Why Supply Chain Connectivity Matters

Supply chain connectivity has become essential rather than optional. A recent survey revealed 45% of manufacturers have made efforts to improve their end-to-end supply chain visibility over the last year. This focus stems from compelling benefits:

First, connected supply chains allow for holistic decision-making. Instead of isolated decisions within silos, organizations can optimize entire networks using data-driven insights to identify bottlenecks, optimize routes, and allocate resources effectively.

Additionally, connectivity helps mitigate risks during disruptions. Being part of an effective network means you’re easily identified as an alternate supplier, helping manufacturers improve supply chain diversity and resilience.

Furthermore, operational excellence promotes customer loyalty and satisfaction. When companies leverage planning applications together with connectivity, they access clean demand data and reliable forecasting algorithms.

B2B technologies like Electronic Data Interchange (EDI), Value-Added Networks (VANs), Global Data Synchronization Networks (GDSN), and Product Information Management (PIM) systems form the backbone of connected supply chains by facilitating secure, standardized data exchange between partners. These solutions enable seamless communication across complex supply networks—a topic we’ll explore further in subsequent sections.

As one industry expert noted, “Visibility, traceability, and interoperability are essential to connected, agile and more resilient supply systems”. Due to increasing global complexity, these capabilities have never been more critical.

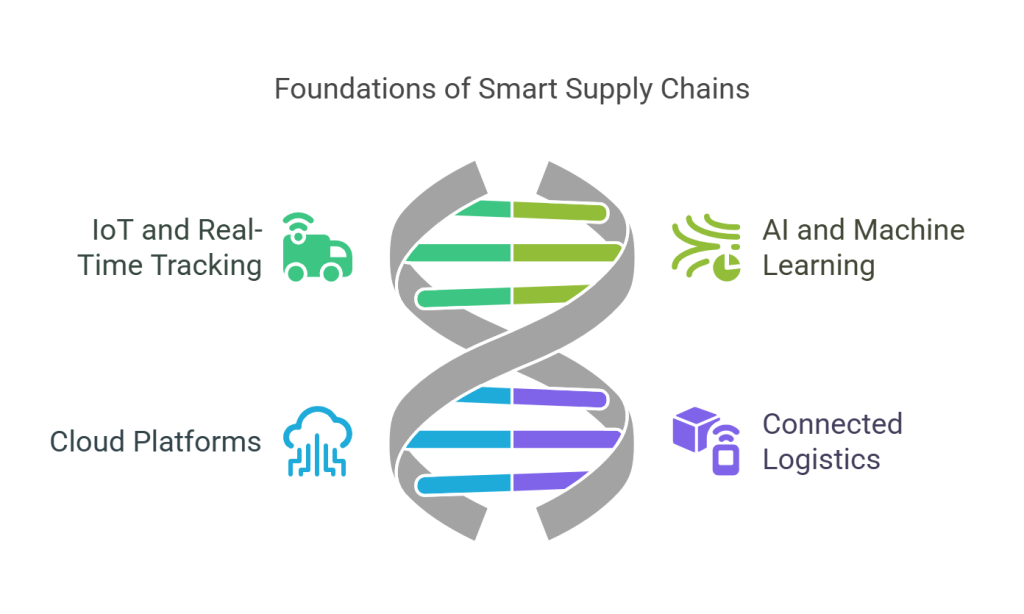

Core Technologies Powering Smart Supply Chains

The technological backbone of modern supply chains relies on four key innovations that are reshaping how goods move from production to consumption. These technologies work in concert to create truly connected supply chain systems that respond dynamically to changes.

1. IoT and real-time tracking

Internet of Things (IoT) technology has fundamentally transformed supply chain visibility. With IoT sensors on products and vehicles providing real-time location data, companies can monitor shipments from source to destination. The global market worth of IoT in supply chain management is projected to reach $41.80 billion by 2033, growing at a CAGR of 12.9%. Beyond location tracking, these sensors monitor environmental conditions, particularly valuable for temperature-sensitive products. Companies like Maersk utilize Industrial IoT solutions to oversee refrigerated containers, ensuring optimal conditions throughout transportation.

2. AI and machine learning for predictive insights

Artificial Intelligence (AI) serves as the analytical engine behind smart supply chains, boosting efficiency by up to 40% through data analysis, trend forecasting, and task automation. McKinsey reports that early AI adopters have improved logistics costs by 15%, reduced inventory levels by 35%, and enhanced service levels by 65%. Machine learning algorithms like K-Means clustering segment shipping routes to optimize container allocation, while predictive maintenance systems detect equipment wear and tear before failures occur.

3. Cloud platforms and data integration

Cloud-based platforms provide the centralized infrastructure essential for connected supply chains. These platforms offer accessibility from anywhere, allowing companies to coordinate supply chain activities more effectively. Solutions like Blue Yonder’s data cloud eliminate integration complexities by streamlining data management across ERP, CRM, WMS, SCM, and e-commerce systems. Notably, running supply chain services on cloud platforms can deliver a 10x improvement in processing speed and a 20x reduction in costs.

4. Connected logistics and automation

Connected logistics ties all aspects of supply chain operations together through a system of interconnected devices. Automation technologies—including robotics, digital twins, and autonomous data collection systems—enhance control and streamline operations. Specifically, drones and mobile robots autonomously capture inventory data in warehouses, significantly reducing time and risk compared to manual counts.

How B2B Solutions Enable Supply Chain Connectivity

Beyond the hardware innovations driving supply chain modernization, specialized B2B solutions serve as the connective tissue that enables true end-to-end visibility and communication. These technologies form the digital foundation for partner collaboration across connected supply chains.

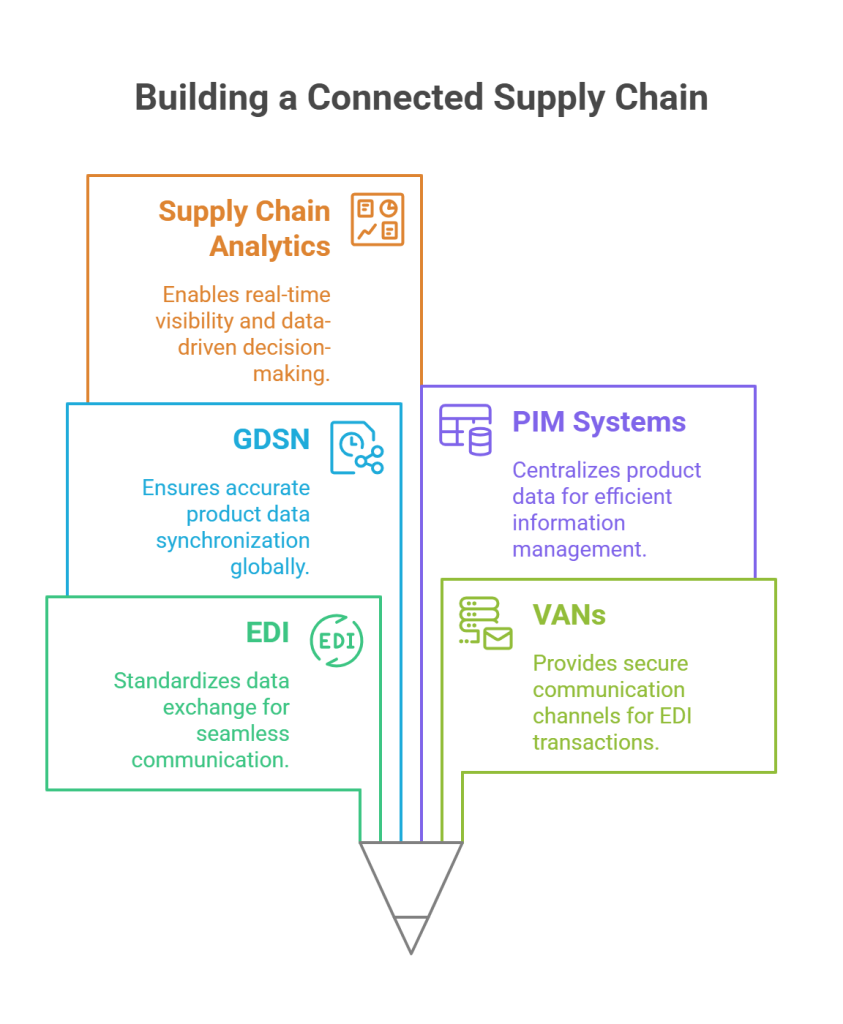

1. Role of EDI in Seamless Data Exchange

Electronic Data Interchange (EDI) transforms how supply chain partners communicate by standardizing and automating document exchange. This technology converts critical documents like purchase orders, shipping notifications, and invoices into standardized digital formats, enabling different systems to communicate effortlessly. By eliminating manual processes, EDI significantly decreases error rates while improving transaction speed, turning days of paperwork into minutes of digital processing. Moreover, EDI offers operational savings by eliminating paper, postage, and manual labor costs traditionally associated with document processing.

2. Using VANs for Secure Partner Communication

Value-Added Networks (VANs) provide secure communication channels for EDI transactions between trading partners. Acting as virtual mailboxes, VANs manage incoming and outgoing messages while analyzing their contents to check for errors. These networks enable businesses to trade reliably through a single connection point rather than managing multiple direct connections to partners. Consequently, VANs reduce trading partner touchpoints while providing a complete audit trail of all transactions.

3. GDSN for Standardized Product Data

The Global Data Synchronization Network (GDSN) solves the intricate challenge of sharing accurate product information among trading partners. As the world’s largest product data network, GDSN enables continuous synchronization of standardized product data between manufacturers and retailers in real-time. Through interconnected data pools, the network ensures trading partners always have correct, up-to-date information about products moving through the global supply chain.

4. PIM Systems for Centralized Information Management

Product Information Management (PIM) systems centralize and streamline product-related data across multiple channels. These platforms integrate with e-commerce systems, CRM, and ERP software to create a single source of truth for product information. With PIM, companies can organize product information into catalogs and link those catalogs to channels, helping teams rapidly obtain needed information while eliminating data silos. This centralization enhances the efficiency of sales and marketing teams while ensuring data quality throughout the product lifecycle.

5. Supply Chain Analytics

Supply chain analytics plays a pivotal role in building a truly connected supply chain by enabling real-time visibility, predictive insights, and data-driven decision-making across all nodes of the network. By integrating data from suppliers, manufacturers, logistics providers, and retailers, analytics tools help identify patterns, optimize inventory levels, reduce disruptions, and forecast demand with greater accuracy. This connected intelligence ensures that every stakeholder is aligned, responsive, and agile—allowing for seamless collaboration, faster cycle times, and improved customer satisfaction. Ultimately, supply chain analytics transforms fragmented operations into a cohesive, intelligent ecosystem.

Commport B2B Solutions Can Help You Streamline Your Supply Chain Operations. Our Solutions Include EDI, VAN, GDSN, PIM and Business Analytics to create a truly connected supply chain experience.

Business Benefits of a Truly Connected Supply Chain

Implementing a connected supply chain delivers measurable business advantages that extend far beyond technological improvements. Organizations with fully integrated supply chains consistently outperform their competitors across multiple performance metrics.

1. Improved Visibility and Traceability

Supply chain traceability enables companies to track products throughout their lifecycle, allowing quick identification of quality issues. This capability is particularly vital for industries where safety and compliance are paramount. Overall, companies with enhanced visibility gain a comprehensive real-time overview of inventory and activity status. Improved tracking helps businesses understand inventory levels and delivery efficiency while ensuring that the right products are available on demand. Likewise, traceability simplifies the audit process by providing precise compliance records across every supply chain step.

2. Faster Response to Disruptions

Supply chain disruptions caused by natural disasters, human threats, and legislative changes have become increasingly common. Essentially, only 2% of companies reported being prepared for such challenges. Connected supply chains allow organizations to identify potential problems before they occur and take corrective actions early, thus minimizing their impact. Through detailed traceability, businesses can quickly pinpoint issues and implement solutions, reducing downtime during critical situations. This proactive approach creates resilience against inevitable disruptions.

Better Customer Experience

Approximately 83% of supply chain leaders report being asked to improve customer experience as part of their digital business strategy. Indeed, connected supply chains can provide accurate information to customers about their orders, helping reduce complaints and improve satisfaction. Web scraping and sentiment analysis tools monitor social media trends that might cause sudden demand surges of 10-15%. Simultaneously, this consumer data helps companies understand who their customers are, what they value, and how they behave after purchases.

4. Cost Savings and Operational Efficiency

Connected supply chains drive significant financial benefits through:

- 10-20% reduction in manufacturing, warehousing, and distribution costs from AI implementation

- Improved inventory management preventing overproduction and underproduction

- Reduced waste in materials, time, and expertise

In essence, B2B solutions like EDI, VANs, GDSN, and PIM systems further enhance these efficiencies. EDI eliminates paper, postage, and manual labor costs while VANs manage communication securely. GDSN ensures real-time product data accuracy, and PIM systems create a single source of truth—all contributing to a truly connected supply chain that simultaneously improves customer satisfaction and reduces operational costs.

Conclusion

Throughout this exploration of connected supply chains, we’ve seen how traditional fragmented models no longer suffice in our complex global economy. After all, with 81% of companies lacking full visibility and 54% having none at all, the need for transformation is undeniable.

The technologies powering this revolution work together to create truly resilient networks. IoT devices provide real-time tracking and condition monitoring, while AI and machine learning analyze vast datasets to predict disruptions before they occur. Meanwhile, cloud platforms serve as the central nervous system, connecting disparate systems across organizational boundaries.

Undoubtedly, B2B solutions form the digital foundation that makes true connectivity possible. EDI standardizes communications between partners, whereas VANs secure these exchanges across complex networks. Similarly, GDSN ensures product data remains consistent and accurate throughout the supply chain, and PIM systems establish a single source of truth for all stakeholders.

The benefits of this connectivity extend far beyond operational improvements. Companies with connected supply chains experience enhanced visibility, faster disruption responses, improved customer experiences, and significant cost savings. Commport B2B Solutions Can Help You Streamline Your Supply Chain Operations. Our Solutions Include EDI, VAN, GDSN, PIM and Business Analytics to create the integrated experience needed in today’s complex environment.

Though implementing a connected supply chain requires investment and organizational change, the cost of inaction grows steeper each year. Companies that embrace connectivity now will find themselves well-positioned for 2025 and beyond, while those that hesitate risk falling further behind. The question therefore isn’t whether your supply chain should become connected, but rather how quickly you can make it happen.

Commport B2B Solutions

Frequently Asked Questions

The core technologies powering smart supply chains include IoT for real-time tracking, AI and machine learning for predictive insights, cloud platforms for data integration, and connected logistics and automation systems. These technologies work together to create truly responsive and efficient supply chain networks.

B2B solutions like Electronic Data Interchange (EDI), Value-Added Networks (VANs), Global Data Synchronization Networks (GDSN), and Product Information Management (PIM) systems enable seamless data exchange, secure partner communication, standardized product information, and centralized information management, respectively. These solutions form the digital foundation for effective supply chain connectivity.

The key benefits include improved visibility and traceability, faster response to disruptions, enhanced customer experience, and significant cost savings and operational efficiency. Connected supply chains allow for better decision-making, risk mitigation, and overall performance improvement across the entire network.

AI is revolutionizing supply chain management by boosting efficiency through data analysis, trend forecasting, and task automation. Early AI adopters have reported improvements in logistics costs, inventory levels, and service levels. AI algorithms are being used for optimizing shipping routes, predicting maintenance needs, and enhancing overall supply chain performance.

Supply chain connectivity is becoming essential due to increasing global complexity and the need for real-time visibility. Connected supply chains allow for holistic decision-making, better risk mitigation during disruptions, and improved customer satisfaction. As traditional fragmented models become obsolete, businesses that embrace connectivity are better positioned to compete in the complex supply landscape of 2025 and beyond.