Introduction

Supply chain optimization has become essential for businesses striving to remain competitive in today’s fast-paced market.

According to a recent KPMG survey, 60% of respondents indicated plans to invest in digital technology to improve their supply chain processes by late 2027.

This significant trend highlights how critical efficient supply networks have become for modern organizations.

What is supply chain optimization exactly?

It’s a strategic imperative. From inventory management and procurement to product data accuracy and delivery efficiency, optimization impacts every link in the supply chain.

With the help of modern digital technologies such as EDI (Electronic Data Interchange), VAN (Value-Added Network), GDSN (Global Data Synchronization Network), and PIM (Product Information Management), businesses can transform their supply chains into agile, data-driven engines of growth.

Understanding the Basics of Supply Chain Optimization

The foundation of efficient business operations rests on understanding exactly what makes supply chains work at their peak performance.

Let’s explore the fundamental concepts and importance of this critical business function.

What is supply chain optimization?

Supply chain optimization fundamentally involves adjusting a supply chain’s operations to ensure it reaches maximum efficiency and effectiveness.

Unlike simple supply chain management, optimization goes beyond basic oversight—it’s about finding the critical optimal solutions that generate the most productive and lucrative organizational performance.

At its core, supply chain optimization encompasses any activities that improve the efficiency and cost-effectiveness of a supply chain network. This includes reducing material waste, developing backup strategies for unexpected sourcing issues, and improving product delivery speed and accuracy.

Supply chain optimization typically addresses three key areas:

- Cost optimization: Analyzes each cost area in the supply chain (orders, storage, transportation, stock) to identify potential reductions

- Inventory optimization: Determines ideal inventory levels needed to satisfy customer demand while minimizing excess

- Network optimization: Improves every part within the supply chain to maximize productivity and profitability

The process is not a one-time task but rather an ongoing vigilance. Most supply chain leaders begin by collecting comprehensive supply chain data through data warehouses or data lakes, then analyzing this information to generate actionable insights for cost reduction, improved resiliency, and sustainability.

Why is Supply Chain Optimization Important in today's global economy

Supply chain optimization matters now more than ever because it directly impacts both operational efficiency and customer satisfaction. According to a KPMG survey, 67% of organizations reported that meeting customer expectations for speedy delivery would be one of their top priorities. This reflects the growing demands that only optimized supply chains can meet.

The global economy relies heavily on efficient supply chains to bridge gaps between producers and consumers. Consequently, organizations with optimized supply chains enjoy several competitive advantages:

- Reduced operating costs through streamlined operations and elimination of inefficiencies

- Enhanced ability to adapt to market fluctuations and disruptions

- Better supplier performance through real-time data visibility

- Improved quality management is built into end-to-end production processes

- Stronger environmental sustainability through reduced carbon emissions and waste

Essentially, supply chain optimization enables businesses to be more agile and responsive. This flexibility is crucial for multinational corporations navigating geopolitical shifts, trade restrictions, and economic fluctuations. Organizations that adopted agile supply chain models during recent disruptions were better equipped to adapt to sudden changes in demand and supply.

Furthermore, the evolution of supply chain optimization has shifted focus from traditional network design to execution-oriented applications and real-time decision support. Today’s optimization leverages technologies like artificial intelligence, machine learning, Internet of Things, and digital twin systems to support data analysis, predictive modeling, and real-time visibility.

Ultimately, a well-optimized supply chain ensures not just survival but sustainable growth in today’s competitive global marketplace.

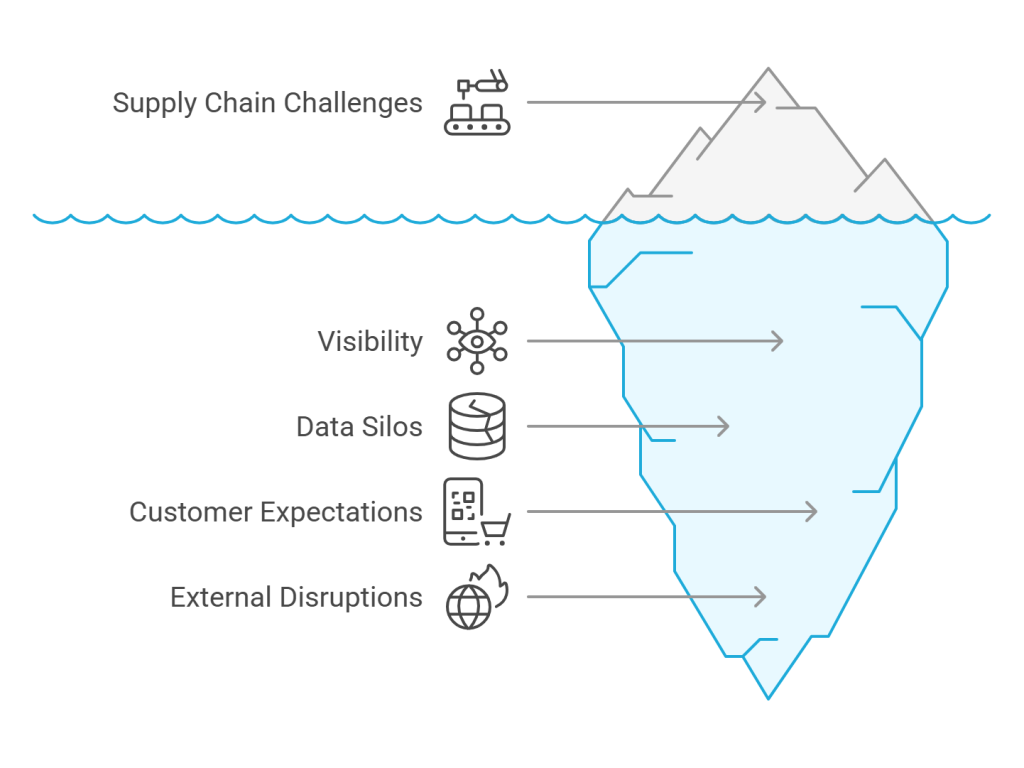

Common Challenges in Supply Chain Management

Even the most sophisticated supply chains face significant hurdles that can derail performance. According to McKinsey’s Global Supply Chain Leader Survey, nine in ten respondents encountered supply chain challenges in 2024. These obstacles continue to multiply in complexity, creating pressure points throughout global operations that require innovative solutions.

1. Siloed Data and Lack of Visibility

Data silos represent one of the most damaging barriers to effective supply chain management. These isolated pockets of information—inaccessible to the entire organization—create a fractured view of operations. When departments operate with separate data systems, they effectively work out of sync, making decisions based on outdated, static information.

The consequences are substantial. Without visibility across multiple supply chain layers, companies struggle to identify and mitigate risks. Alarmingly, 94% of businesses lack full visibility of their supply chain operations. This blindness creates what many companies describe as a “black hole” where orders disappear after placement.

Moreover, the challenge is worsening. The percentage of companies reporting good visibility into deeper supply chain levels fell by seven percentage points in the most recent annual assessment. This decline is particularly concerning since major disruptions often originate deep within the supply chain network.

2. Rising Customer Expectations

Today’s consumers have dramatically transformed what they demand from supply chains. In a 2022 survey of online shoppers, 90% expected free delivery within five days, with 62% demanding it within just three days. These expectations place enormous pressure on supply networks to perform flawlessly.

Additionally, the digital transformation of commerce has shifted how retailers approach their operations. Modern customers expect more than just speed—they demand transparency, customization, and sustainability throughout their buying journey. According to Gartner, 83% of surveyed supply chain leaders report being asked to improve customer experience as part of their organization’s digital business strategy.

This evolution requires organizations to innovate and optimize every step of the shipping process. Supply chains must become more agile to meet rapidly evolving consumer needs while keeping pace with shifting market demands.

3. Geopolitical and Environmental Disruptions

Recent years have demonstrated how vulnerable global supply chains are to external forces beyond corporate control. Climate-related disasters have repeatedly fractured critical supply nodes. For instance, flooding in Central China disrupted supply chains for commodities like coal and forced the closure of automotive plants. Similarly, drought in Brazil severely impacted a key Amazon port, preventing essential deliveries to remote villages.

The financial implications are staggering. By mid-century, climate disruption to global supply chains could lead to up to $25 trillion in net losses. Meanwhile, geopolitical tensions between major economic blocs are constricting business operations through sanctions, tariffs, and fragmented trade policies.

These challenges intensify when multiple disruptions occur simultaneously. Notably, the Malaysia node in the global semiconductor supply chain—which hardly anyone recognized as critical—severely impacted global electronics availability when disrupted. Furthermore, most organizations remain underprepared for these threats, with only 25% of companies having formal processes to discuss supply chain risks at the board level.

Despite these formidable challenges, supply chain optimization techniques offer promising solutions to enhance resilience, visibility, and performance amid increasing complexity.

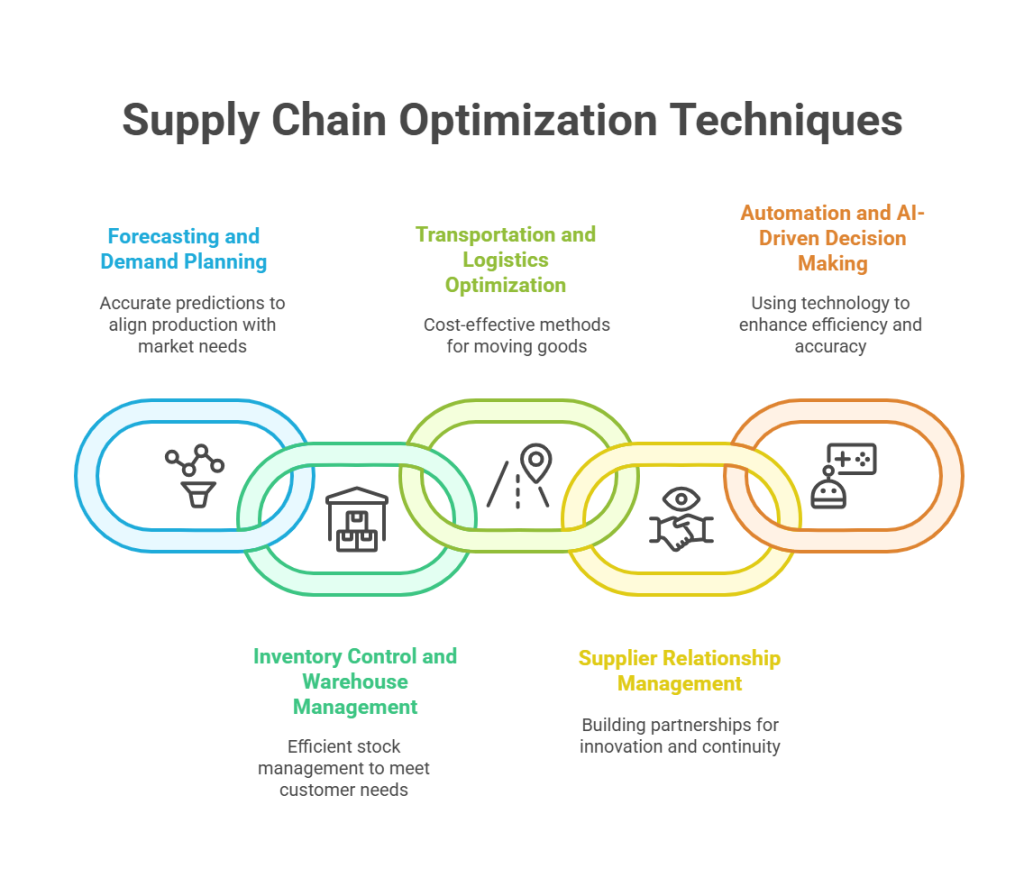

Top Supply Chain Optimization Techniques

Successful businesses embrace specific techniques that transform their supply chains from cost centers into strategic assets. By implementing these proven approaches, companies can overcome common challenges while creating resilient and responsive operations that drive competitive advantage.

1. Forecasting and demand planning

Accurate demand forecasting forms the backbone of effective supply chain optimization. This technique combines qualitative and quantitative data to predict future product demand, allowing businesses to align production with actual market needs. According to industry research, warehouses implementing advanced forecasting systems achieve remarkable inventory accuracy rates of up to 95%, compared to just 60% in traditional setups.

Effective demand planning requires breaking down data silos and gathering insights from multiple sources. Companies utilize both macro-level forecasting (examining broader economic conditions) and micro-level forecasting (focusing on specific products or regions) to create a complete picture. This dual approach helps businesses navigate complexities like seasonality, changing customer preferences, and unexpected market shifts.

To implement this technique effectively, organizations should:

- Feed forecasting software with diverse data sources

- Regularly update projections based on real-time information

- Develop clear processes for the demand planning cycle

- Balance historical trends with forward-looking intelligence

2. Inventory Control and Warehouse Management

Inventory optimization balances having sufficient stock to meet customer needs without tying up excessive capital in warehouse goods. This delicate equilibrium requires strategic management of safety stock levels, proper storage utilization, and accurate tracking systems.

A well-chosen warehouse management system (WMS) centralizes data and automates traditionally error-prone tasks such as receiving, shipping, storage, and picking. Initially requiring investment, these systems deliver substantial long-term benefits, including more accurate inventory counts, better order efficiency, and reduced operational costs.

Effective inventory control also involves sophisticated approaches like ABC analysis, which categorizes inventory based on value to prioritize management efforts. This strategic segmentation ensures companies focus resources on the most critical items while maintaining appropriate oversight of lower-value products.

3. Transportation and Logistics Optimization

Logistics optimization identifies the most efficient and cost-effective methods for moving goods throughout the supply chain. According to research, optimizing freight can yield an ROI ranging from 4% to 8% on freight costs.

Key aspects of transportation optimization include route planning, cargo maximization, and cost reduction. Route optimization software, incorporating satellite maps, traffic patterns, and delivery windows, helps companies determine the most efficient delivery paths. This technology can dramatically reduce fuel consumption, minimize delays, and improve customer satisfaction through on-time deliveries.

Beyond route planning, logistics optimization encompasses strategic approaches like Just-in-Time delivery and last-mile optimization that further enhance efficiency and customer experience.

4. Supplier Relationship Management

Strategic supplier relationship management (SRM) evaluates vendors to determine their contribution to business success and develops strategies to improve their performance. Rather than focusing solely on cost, effective SRM builds mutually beneficial partnerships that drive innovation and competitive advantage.

The process typically involves segmenting suppliers by importance, developing appropriate management frameworks for each category, and establishing clear communication channels. Through this structured approach, companies gain better access to supplier capabilities, reduce costs, ensure supply chain continuity, and limit potential risks.

5. Automation and AI-Driven Decision Making

Artificial intelligence and automation represent the frontier of supply chain optimization. These technologies handle routine tasks with limited human intervention, allowing businesses to scale operations efficiently while improving accuracy.

AI applications in supply chains include real-time data analysis, demand prediction, route optimization, and inventory management. According to industry studies, AI systems can reduce forecasting errors by 50%, leading to more dependable supply chains and reduced waste. Furthermore, automated systems can process vast amounts of data to optimize warehouse layouts, improve delivery routing, and minimize product waste in marketplaces.

The integration of these technologies ultimately delivers benefits throughout the supply chain—from enhanced back-office efficiencies to improved customer experiences through faster, more accurate order fulfillment.

Technologies That Drive Supply Chain Optimization

Supply chain optimization depends heavily on data, automation, and connectivity. Some integration-focused tools like EDI, VAN, GDSN, and PIM are essential for creating a unified, accurate, and scalable supply chain infrastructure. These B2B integration tools will directly connect to other backend systems like

- ERP (Enterprise Resource Planning) – Manages internal processes

- WMS (Warehouse Management System) – Handles warehousing and inventory

- TMS (Transportation Management System) – Optimizes shipping and logistics

- AI/ML (Artificial Intelligence / Machine Learning) – Powers forecasting and analytics

- IoT (Internet of Things) – Provides real-time tracking and condition monitoring

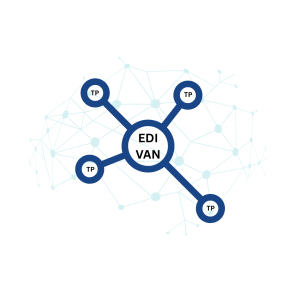

The Role of EDI and VAN in Supply Chain Optimization

EDI replaces time-consuming, error-prone paper-based communication with fast, automated processes. VAN facilitates data exchange between trading partners. It acts as a middle layer that simplifies communication and ensures reliability and compliance

Together they help streamline many processes, like,

- Faster Order Processing: Automates order-to-cash and procure-to-pay cycles.

- Error Reduction: Eliminates manual data entry errors.

- Improved Visibility: Provides real-time transaction tracking.

- Compliance: Ensures compatibility with trading partner systems and regulatory requirements.

- Scalability: Easily connects to new trading partners.

- Security and Encryption: Protects sensitive business documents.

- Data Translation: Converts documents into compatible formats.

- Message Tracking: Provides delivery confirmations and audit trails.

- Partner Onboarding: Streamlines the setup of new EDI connections.

- Maintenance-Free Infrastructure: Reduces internal IT burden.

The Role of GDSN and PIM in Supply Chain Optimization

GDSN allows trading partners to share standardized product data globally. PIM is a centralized platform for managing product data across all sales and distribution channels.

Together they help with,

- Real-Time Synchronization: Ensures accurate, up-to-date product data across all partners.

- Compliance Assurance: Aligns with industry and regulatory standards (GS1).

- Reduces Errors: Minimizes inconsistencies in product listings and labels.

- Accelerates Time-to-Market: Speeds up the launch of new products.

- Data Centralization: Creates a single source of truth for product content.

- Content Enrichment: Improves product detail quality, enhancing buyer confidence.

- Channel Consistency: Ensures uniform product representation across platforms.

- Localization: Supports multilingual and regional compliance needs.

How These Solutions Work Together

When EDI, VAN, GDSN, and PIM are integrated, they create a seamless digital supply chain infrastructure that supports optimization at every level.

Integration Use Case:

- EDI receives a purchase order

- VAN securely transmits the document to the supplier

- Supplier retrieves product data from PIM and GDSN

- An accurate product is picked, packed, and shipped

- Invoices and ASN are returned via EDI

This integrated approach ensures that data flows effortlessly between systems, reducing delays, errors, and inefficiencies.

Benefits of Supply Chain Optimization

Operational Efficiency

- Automated workflows and fewer manual interventions

- Faster turnaround times

Cost Savings

- Reduced administrative and inventory costs

- Lower transportation expenses

Enhanced Collaboration

- Better communication with suppliers, partners, and customers

Data Accuracy

- Real-time insights and reliable data for decision-making

Improved Customer Experience

- Timely delivery, accurate orders, and consistent product information

Competitive Advantage

- Agile response to market trends and disruptions

Environmental Impact

- Less waste and lower emissions through optimized logistics

Conclusion

Supply chain optimization has undeniably evolved from a mere business function to a critical competitive differentiator. Despite facing significant challenges such as data silos, increasing customer expectations, and unprecedented global disruptions, businesses have powerful tools at their disposal. Effective forecasting, inventory control, transportation management, supplier relationships, and AI-driven automation collectively create supply chains that can withstand volatility while delivering exceptional performance. Therefore, organizations that invest in these optimization techniques position themselves for sustainable growth in an increasingly complex marketplace.

Finally, remember that supply chain optimization represents a journey rather than a destination. Successful companies approach it as an ongoing process with continuous assessment, technology adoption, team alignment, and performance monitoring. By following the systematic approaches outlined in this guide, your organization can build a responsive, efficient supply chain that not only withstands disruptions but thrives amid them.

Commport B2B Solutions

Complete Guide to Supply Chain KPIs

Top 30 Supply Chain KPIs Your Business Should Be Tracking & Measuring

Frequently Asked Questions

Supply chain optimization involves improving the efficiency and effectiveness of a company’s supply network. It uses technologies like AI and data analytics to enhance processes from sourcing to delivery, with the goal of reducing costs, improving customer satisfaction, and increasing overall performance.

Important techniques include demand forecasting, inventory control, transportation management, supplier relationship management, and AI-driven automation. These approaches help businesses streamline operations, reduce waste, and respond more effectively to market changes.

Optimized supply chains can lead to reduced operational costs, improved customer service, enhanced resilience to disruptions, better inventory management, and increased profitability. It also enables companies to be more agile and responsive in today’s complex global marketplace.

? Common challenges include dealing with siloed data, meeting rising customer expectations, and managing disruptions from geopolitical and environmental factors. Overcoming these obstacles often requires innovative solutions and cross-functional collaboration.

IBM’s implementation of a cognitive supply chain yielded impressive results, including $160 million in cost savings through inventory optimization and improved decision-making. During peak pandemic disruptions, they maintained a 100% order fulfillment rate globally, showcasing the power of an optimized supply chain.