Introduction

EDI ERP integration mistakes can devastate your bottom line.

Did you know that about half of all ERP implementations fail the first time around, often because companies underestimate integration complexities?

When we examine what EDI integration truly involves versus a typical ERP system implementation, the complexity becomes clear. Companies that fail to consider integration requirements early in the ERP migration process typically face costly last-minute solutions that significantly increase complexity.

The consequences of poor integration extend beyond direct costs. Inefficient business management systems can significantly impact order processing, resulting in frustrated customers and lost sales. Conversely, effective EDI integration can enhance efficiency, accuracy, and visibility, while also reducing inventory costs. Despite these benefits, we’ve found that customization capabilities in ERP systems can increase project costs by more than 50%, often resulting in error-prone workarounds.

Throughout this article, we’ll explore 11 critical mistakes that could cost your company millions in failed EDI ERP integration projects—and more importantly, how you can avoid them.

- Lack of clear integration objectives

- Over-customizing the ERP system

- Inadequate data migration planning

- Relying on a manual process

- Using built-in EDI tools without evaluation

- Siloed project teams

- Skipping end to end testing

- Underestimating total cost of integration

- Failing to train staff on new systems

- Neglecting post-go-live monitoring

- Poor communication with vendors and partners

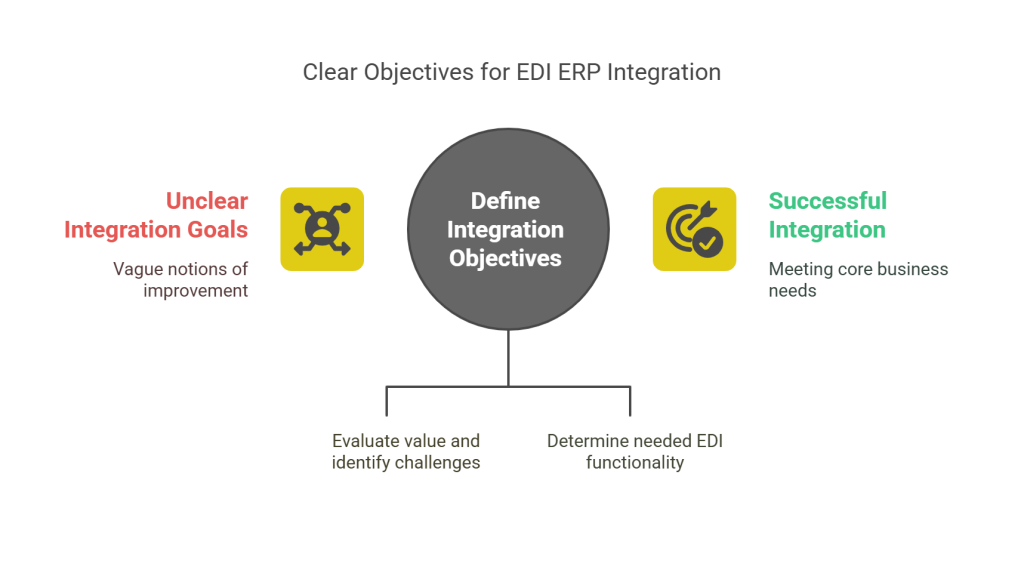

1. Lack of Clear Integration Objectives

Many businesses approach EDI ERP integration without a clear roadmap, setting themselves up for costly failures before they begin. According to a Standish Group report, over 80% of data integration projects either fail or exceed their original budget by more than 170%. This alarming statistic highlights the first critical mistake companies make: proceeding without well-defined integration objectives.

What is the mistake?

Starting an EDI ERP integration project without establishing clear goals creates a foundation of confusion. Companies often initiate these projects with vague notions like “improving efficiency” without specifying exactly what processes need improvement, by what metrics success will be measured, or how the integration aligns with broader business objectives. This lack of clarity leads to scope creep, misaligned expectations, and ultimately, integration that doesn’t address core business needs.

The absence of specific objectives also makes it impossible to gauge the success of each integration milestone, increasing the risk of costly mid-project corrections or complete failure. Without clear criteria for what constitutes successful integration, projects drift aimlessly, consuming resources without delivering meaningful value.

Why it happens

This mistake typically occurs because organizations underestimate the complexity of EDI ERP integration. In their eagerness to implement new technology, they skip crucial planning phases. Furthermore, the technical nature of integration projects sometimes leads business leaders to delegate planning entirely to IT departments, creating a disconnect between technical implementation and business requirements.

Additionally, many companies fail to conduct proper internal risk and needs assessments that would help determine the true value of integration and identify potential challenges beforehand. Without this foundational work, organizations cannot articulate what functionality they need from their EDI integration, leading to poor decision-making throughout the project.

How to avoid it

To avoid this costly mistake, begin with a comprehensive internal risk and needs assessment to evaluate the value of integration, identify challenges, and calculate potential return on investment. This assessment helps determine exactly what functionality you need from your EDI integration.

Next, define the scope of work by:

- Clearly articulating your ERP interfaces

- Establishing specific testing and acceptance criteria

- Creating a realistic launch schedule with defined milestones

Ensure alignment between technical integration plans and business objectives by involving stakeholders from across the organization in planning discussions. As noted by EDI experts, “critical to effective EDI implementation is a clear set of goals and a solid understanding of your supply chain“.

Finally, create a detailed project plan that outlines specific timelines for each phase of integration, including data migration, testing, and staff training. This comprehensive planning allows you to measure progress at each step and guarantee on-time delivery, accelerating your return on investment.

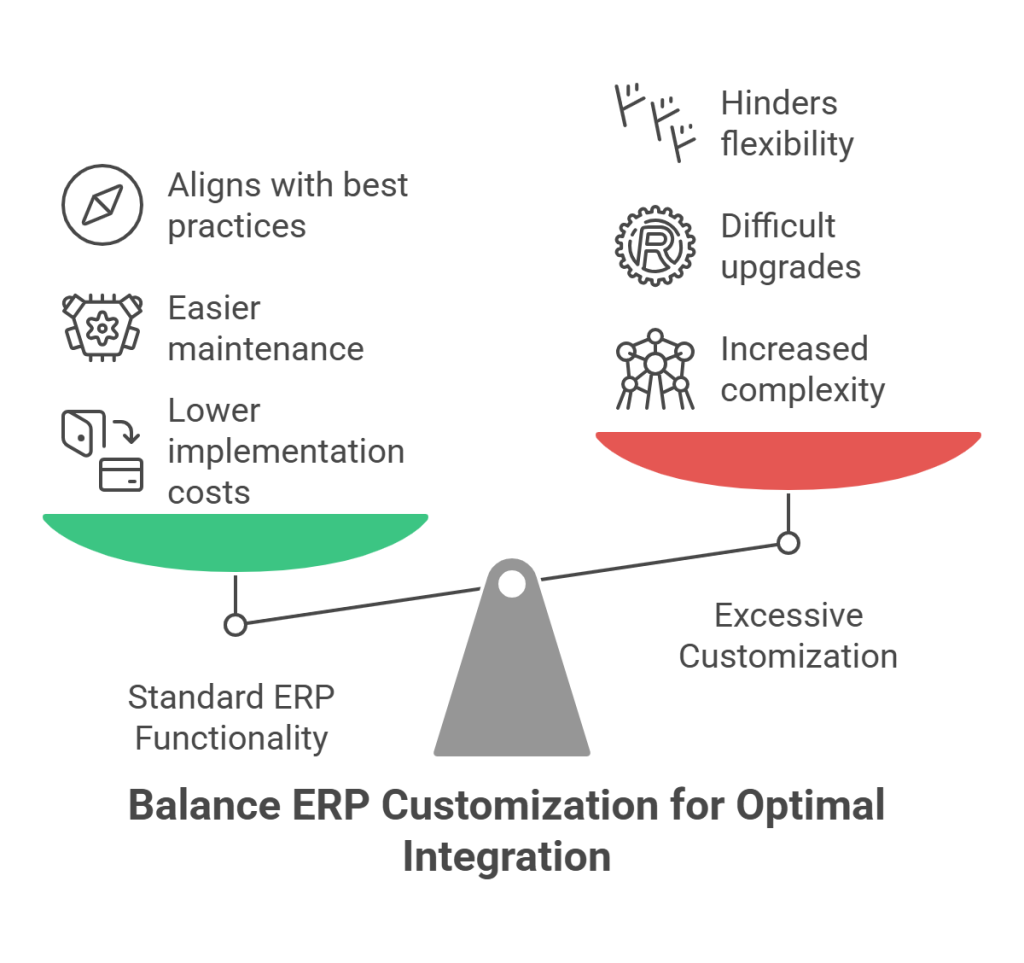

2. Over-Customizing the ERP System

The temptation to extensively customize ERP systems during EDI integration leads many companies into an expensive technological quagmire. Although customization seems like a path to perfect alignment with business processes, excessive modifications frequently become one of the costliest mistakes in integration projects.

What is the mistake?

Over-customization occurs when companies modify an ERP system’s source code or functionality beyond what’s necessary, creating a heavily tailored solution that strays far from the standard version. This approach fundamentally alters how EDI and ERP systems interact. While some customization can benefit specific workflows, excessive modifications can increase implementation costs by more than 50%, creating a complex system that ultimately hinders rather than helps operations.

Moreover, heavily customized ERP systems become increasingly difficult to maintain. Studies show that over-customization can push back go-live dates significantly, postponing the return on investment and creating cascading delays throughout the integration process. Surprisingly, what begins as an attempt to improve functionality often results in a system that no longer aligns with business goals.

Why it happens

Over-customization typically happens when companies attempt to make new systems mirror old processes rather than adapting to industry best practices. This resistance to change, especially from end users accustomed to legacy systems, pushes implementation teams to modify standard ERP functionality unnecessarily.

Additionally, many organizations fail to recognize that modern ERP systems already incorporate industry best practices. The desire for a perfect fit blinds decision-makers to the benefits of standardization. This mindset often stems from a lack of understanding about the true costs of customization, which include not just immediate development expenses but also long-term maintenance challenges.

Consequently, businesses underestimate how customization complicates future upgrades. Excessive modifications can make system updates difficult, costly, and time-consuming, creating a situation where companies eventually fall behind on critical security patches and feature improvements.

How to avoid it

The key to successful EDI ERP integration lies in finding the right balance between standard functionality and necessary customizations. Initially, evaluate whether your unique requirements truly justify modifying the core system. Industry experts recommend limiting customization to no more than 10-15% of the overall ERP system.

To maintain a balanced approach:

- Adopt standard functionality whenever possible, even if it requires adjusting some business processes

- Work with ERP consultants who understand your industry and can advise on minimal, impactful customizations

- Focus on configuration (using built-in tools to adjust settings) rather than customization (changing source code)

- Conduct thorough regression testing for any customizations to ensure they won’t disrupt other system functions

Ultimately, the most successful EDI ERP integration projects are those that embrace the ERP system’s built-in best practices while making selective modifications only where absolutely necessary. This approach ensures your system remains scalable, maintainable, and capable of supporting future business growth without becoming a financial drain.

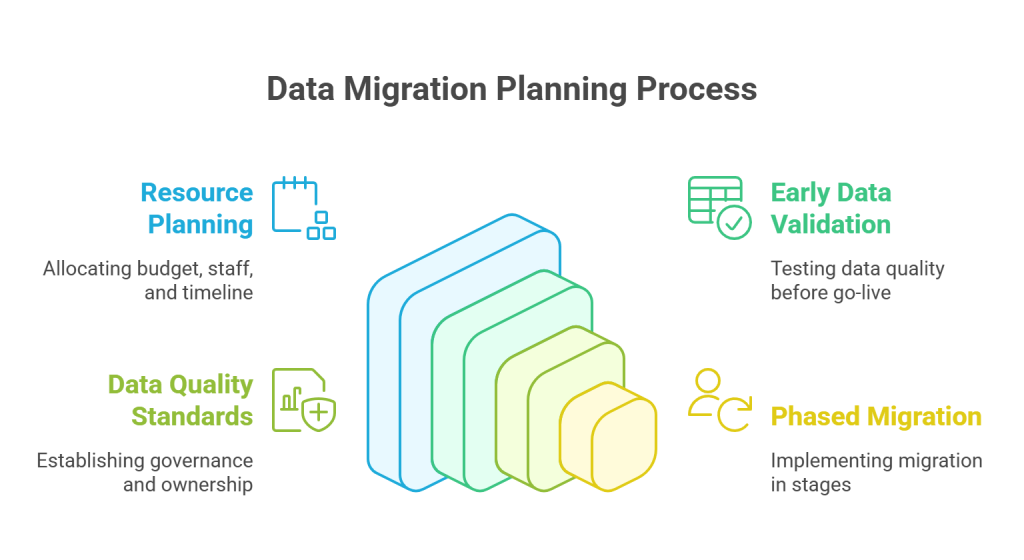

3. Inadequate Data Migration Planning

Data migration failures derail countless EDI ERP integration projects, often with staggering financial consequences. According to Gartner, 55 to 75 percent of ERP projects ultimately fail to meet their objectives, with data migration problems frequently at the heart of these failures. One striking example involved a major supermarket group that wasted seven years and €500 million on a failed SAP implementation primarily due to data migration challenges.

What is the mistake?

Inadequate data migration planning occurs when companies underestimate the complexity and resources required to transfer data between systems. This mistake manifests as poor data quality assessment, insufficient resource allocation, and inappropriate timing of migration activities. Many organizations reach the migration phase only to discover they’ve severely under-staffed the effort, creating costly delays. Subsequently, companies rush the validation process, performing data testing too close to go-live dates instead of earlier in the project.

Why it happens

This critical mistake typically stems from viewing data migration as merely a technical task rather than a business-critical process. Many organizations incorrectly delegate migration responsibilities solely to IT teams without involving key stakeholders from various departments. Additionally, companies often fail to recognize existing data quality issues in legacy systems, including inaccuracies, outdated information, and inconsistencies resulting from manual data entry errors.

Resource constraints likewise contribute to this problem. Companies frequently underbudget for data migration, overlooking the significant costs associated with extracting, cleaning, and rationalizing data. Hence, when stakeholders are unwilling to allocate necessary resources, the entire integration effort becomes compromised.

How to avoid it

To prevent costly data migration failures, begin with a comprehensive assessment of your current systems to understand gaps and improvement areas. Essentially, this evaluation helps create a clear migration roadmap that includes:

- Detailed resource planning for budget, staffing, and timeline requirements

- Early data validation and testing procedures, well before go-live dates

- Clear data quality standards and governance frameworks defining ownership and maintenance processes

Furthermore, implement a phased migration approach to reduce risks, especially for complex data transfers. This approach minimizes system downtime, which can otherwise disrupt business operations.

How Commport Can Help With EDI ERP Integration and Also Offer Custom Integration Solutions

For companies struggling with data migration planning, Commport provides specialized expertise in EDI ERP integration, offering structured migration methodologies that ensure data accuracy and minimize business disruption during the transition process.

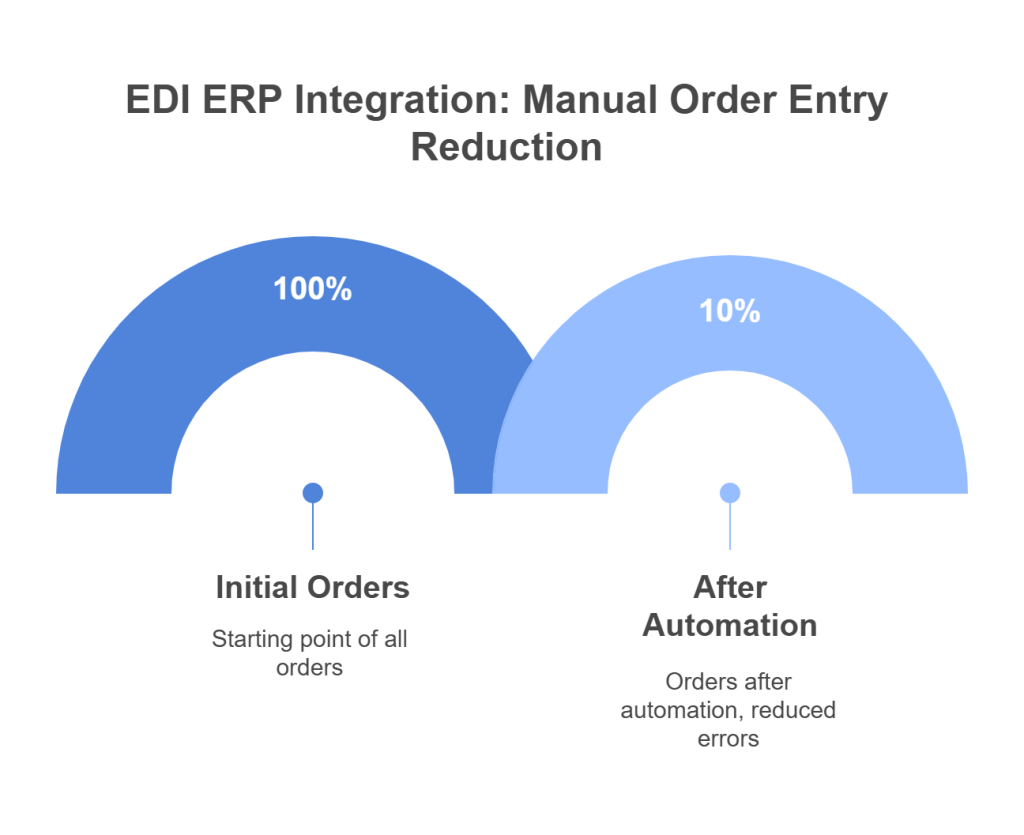

4. Relying on Manual Processes

In the world of EDI ERP integration, maintaining manual processes creates a dangerous blind spot that silently drains resources and introduces costly errors. Despite technological advances, numerous companies still rely on traditional data entry methods, creating inefficiencies that significantly impact their bottom line and operational effectiveness.

What is the mistake?

The fundamental error lies in failing to fully automate EDI processes, leaving critical workflows dependent on manual intervention. Studies show manual data entry has an error rate of approximately 1%, which might seem minor until these errors cascade through interconnected systems. Manual processes remain painfully slow, with employees spending roughly 45% of their time on tasks that could be automated.

Furthermore, retaining manual steps between EDI and ERP systems creates inconsistent data quality and complicates integration. As organizations grow, these manual processes become increasingly problematic—a manufacturing company that integrated EDI with its ERP system eliminated 90% of manual order entry, significantly reducing fulfillment errors.

Why it happens

Organizations cling to manual processes primarily because they underestimate automation’s value while overestimating implementation challenges. Many businesses fail to adapt priorities while scaling operations, resulting in poor management and costly mistakes.

Typically, management lacks awareness about the true costs of manual data entry. Beyond direct labor expenses, companies face hidden costs from error correction, compliance issues, and data loss. Additionally, the perceived complexity of automation solutions often deters implementation.

Most critically, businesses become trapped in the “the way we’ve always done it” mentality. Without recognizing how rigid and slow manual EDI processes are, they continue investing in inefficient workflows rather than automation that could make operations more flexible.

How to avoid it

Embracing end-to-end automation represents the clearest path forward. A fully integrated process without manual input prevents errors, streamlines operations, and improves accuracy. Consider these practical approaches:

- Implement multi-level automation to manage increasing order volumes and improve efficiency

- Use validation rules and verification techniques to ensure data accuracy

- Integrate EDI directly with business systems like ERP to eliminate inefficiencies

- Explore automated data entry tools that operate continuously without human limitations

Undoubtedly, the shift away from manual processes requires investment. Nevertheless, the return clearly justifies the expense—companies report eliminating up to 90% of manual order entry through proper EDI ERP integration. For businesses reluctant to manage EDI in-house, third-party automation solutions offer an alternative path toward efficiency without overwhelming internal resources.

By addressing this critical mistake, organizations not only reduce operational costs but simultaneously enhance data integrity, improve compliance, and create scalable systems capable of supporting business growth.

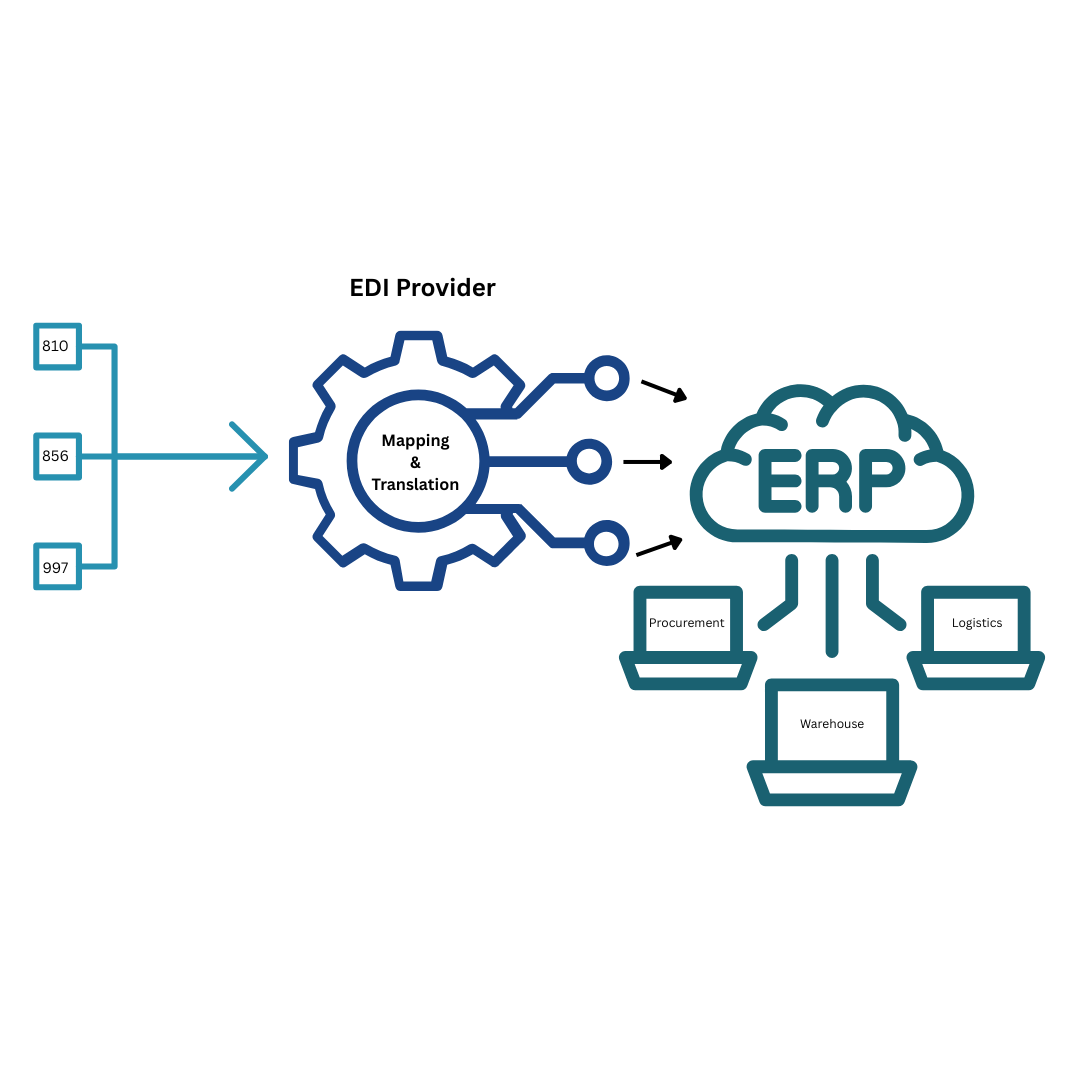

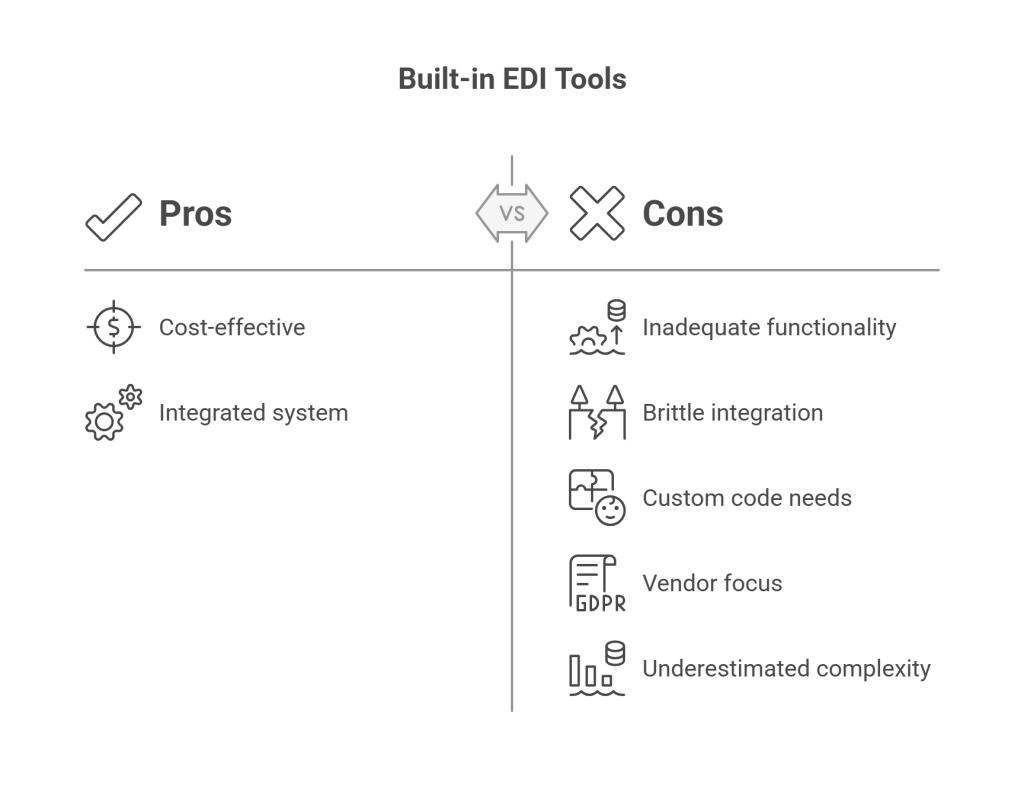

5. Using Built-in EDI Tools Without Evaluation

Companies frequently fall into the trap of defaulting to built-in EDI tools bundled with their ERP systems, a decision that can trigger financial losses and operational inefficiency. This mistake becomes particularly costly as organizations scale their operations and face more complex trading partner requirements.

What is the mistake?

The error lies in assuming that EDI capabilities included within ERP packages will adequately handle complex business-to-business communications. According to industry analysts, up to 75% of all EDI migrations fail, with many of these failures stemming from inadequate EDI functionality within ERP systems. These built-in tools typically offer only lightweight EDI processing that lacks the depth and flexibility needed for modern supply chains.

Notably, ERP-based EDI solutions often create “brittle” integration points that cannot easily adapt to new standards or trading partner requirements. When changes become necessary, organizations frequently discover they must invest unplanned dollars in custom code development outside the EDI component. This reactive approach creates a disjointed technical environment where each workaround adds another layer of complexity and cost.

Why it happens

This mistake occurs primarily because ERP vendors focus on improving their core functionalities, such as order management and inventory, at the expense of front-end processes like EDI partner onboarding. Since EDI is not their main capability or function, ERP providers have little incentive to innovate their EDI modules.

Furthermore, organizations often underestimate the complexity of EDI integration. The perception that “integrated” tools will simplify implementation leads companies to choose convenience over capability. Unfortunately, this convenience frequently comes at the expense of performance, as tightly coupled systems inherently lack the flexibility and agility required for dynamic business environments.

How to avoid it

To prevent this costly mistake:

- Evaluate EDI requirements independently from ERP selection

- Recognize that the most efficient approach lets each system perform its intended function—EDI manages front-end trading partner relationships while ERPs handle back-end processes

- Consider standalone EDI solutions that provide greater flexibility, visibility, and innovation compared to built-in ERP modules

- Assess your current and future trading partner requirements before committing to any EDI solution

How Commport Can Help With EDI ERP Integration and Also Offer Custom Integration Solutions

Commport specializes in providing flexible EDI solutions that integrate seamlessly with various ERP systems while avoiding the limitations of built-in tools. Their expertise helps companies implement standalone EDI engines designed specifically for business process visibility and SLA management—critical capabilities often missing from ERP-based options.

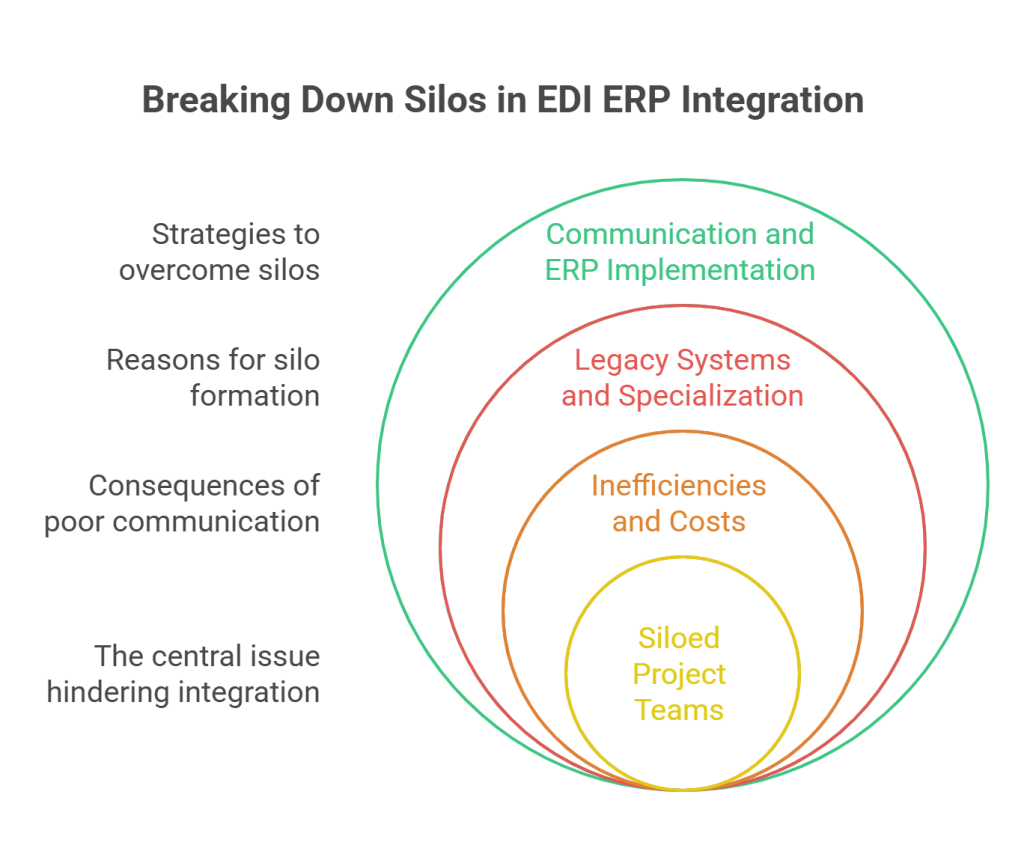

6. Siloed Project Teams

Siloed project teams represent one of the most pervasive structural problems hampering EDI ERP integration success. As organizations expand their technical capabilities, the invisible walls between departments often become the greatest obstacle to effective implementation.

What is the mistake?

The fundamental error occurs when departments involved in EDI ERP integration operate independently with minimal communication or data sharing. These silos typically form around specific operations such as procurement, manufacturing, logistics, and inventory management—each using separate systems and processes. Unfortunately, this fragmentation creates a restricted flow of information between departments, leading to inefficiencies that increase costs and slow response times to market demands.

The repercussions ripple throughout the organization: inconsistent inventory and production data cause delays, excess stock, or missed orders. Meanwhile, manual reconciliation between systems slows reporting and increases errors, resulting in duplicate efforts and damaged internal trust. Without visibility across departments, companies struggle to forecast demand accurately or respond to problems in real-time.

Why it happens

Silos emerge organically as businesses grow more specialized. Over time, departments prioritize immediate needs, developing their systems and databases that don’t communicate effectively. Legacy systems further entrench this problem by perpetuating disconnected processes and fragmented information flows.

Currently, the oversupply of tools and platforms has only amplified this phenomenon. Within organizations, silos manifest when design teams utilize specific software for planning, inventory teams rely on different systems for management, and sales teams track leads with completely different platforms—creating a disjointed operational view.

How to avoid it

Establishing clear, regular communication among teams is crucial for coordination. Implementing an ERP system that provides a centralized platform helps promote communication and collaboration between departments. Prior to implementation, define clear roles and responsibilities for each team member to avoid confusion.

Additionally, foster a culture of continuous feedback where all members feel comfortable sharing ideas for improvements. Use ERP features like real-time dashboards, alerts, and notifications to keep employees informed about activities in other departments. Invest in comprehensive training on the ERP system to ensure everyone can use it efficiently.

By breaking down these silos, companies significantly improve operational performance, reduce lead times, and enhance customer satisfaction.

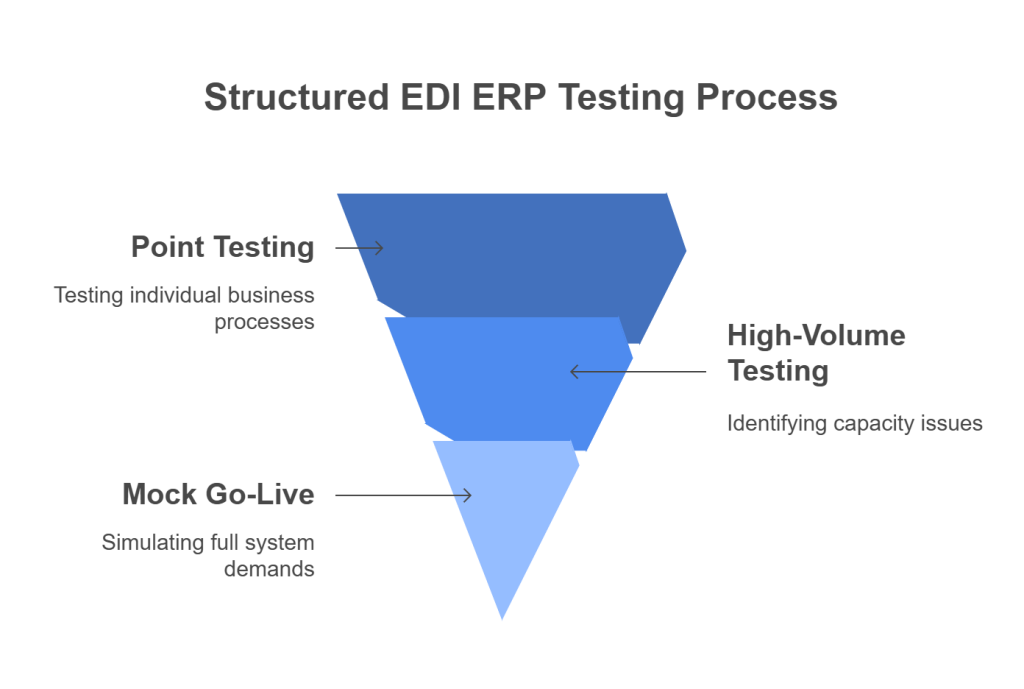

7. Skipping End-to-End Testing

Neglecting thorough end-to-end testing stands as one of the most overlooked pitfalls in EDI ERP integration projects, often leading to catastrophic failures when systems finally go live. This critical mistake frequently separates successful implementations from those that cost companies millions in emergency fixes and lost business.

What is the mistake?

End-to-end testing involves verifying that EDI documents flow correctly between organizations and internal systems before actual implementation. Many companies either skip this crucial step entirely or perform insufficient testing that fails to identify critical issues. Without proper testing, businesses discover problems only after going live, resulting in internal chaos, supply chain disruptions, and financial data inconsistencies. This mistake is particularly dangerous because EDI and ERP systems have many interconnected components that must work together seamlessly.

Why it happens

Companies rush through or entirely skip testing primarily because of tight implementation timelines. Project teams feel pressured to meet deadlines, occasionally sacrificing thorough testing to stay on schedule. Additionally, throughout the implementation process, businesses generally underestimate the complexity of their integrated systems. Each configured ERP application is unique, requiring comprehensive testing of highly integrated and complex business processes.

Failure to recognize that configuration changes in one functional area can impact many others further compounds this problem. Project teams often lack understanding that business processes supported by ERP typically run across multiple functional areas, necessitating end-to-end testing approaches.

How to avoid it

To prevent this costly mistake, implement a structured testing methodology:

- Start with point testing of individual business processes to identify basic functionality issues

- Progress to high-volume workload testing to uncover capacity problems

- Conduct a complete mock go-live that simulates the full spectrum of demands the system will face

Certainly recognize that EDI testing must include not just your EDI portal but extend fully to your back-end ERP. For example, when testing an EDI 850 (purchase order), verify it properly enters your accounting software; similarly, ensure EDI 810 (invoices) flow correctly from your accounting system through your EDI portal to trading partners.

Henceforth, consider this testing phase one of the most important stages in your EDI ERP integration project—skipping it virtually guarantees unexpected problems in production that can derail your entire implementation.

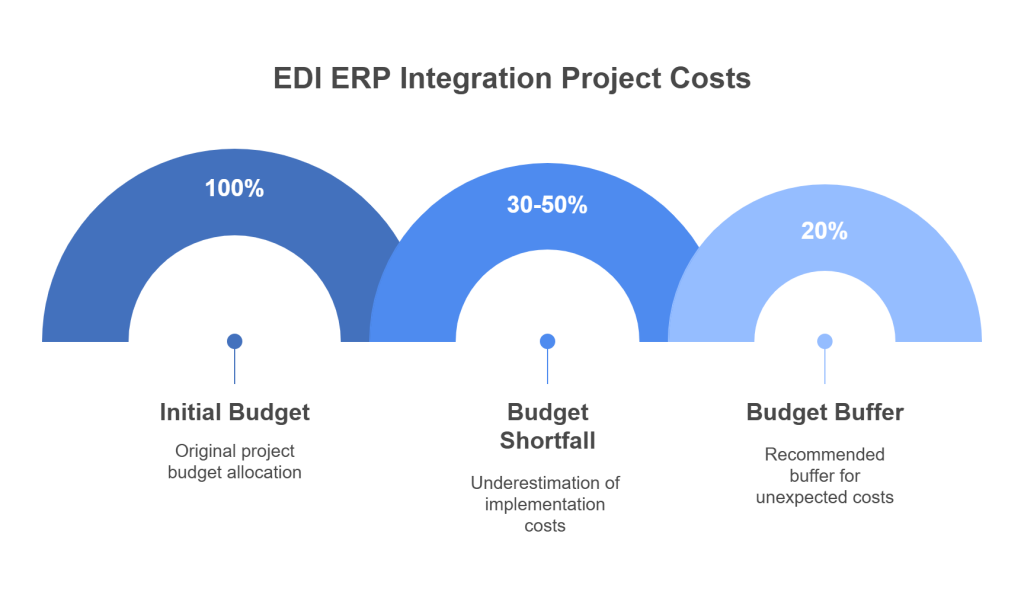

8. Underestimating Total Cost of Integration

Financial misconceptions in EDI ERP integration projects frequently lead to budget overruns that can devastate company finances. Indeed, many organizations focus solely on immediate implementation costs while missing the complete financial picture of integration.

What is the mistake?

Underestimating total integration costs occurs when companies fail to calculate the complete financial impact beyond initial software purchases. This narrow focus ignores ongoing expenses that significantly affect long-term budgets. Most companies underestimate implementation costs by 30-50%, creating major budgetary shortfalls.

The mistake extends beyond miscalculating upfront costs—it encompasses overlooking:

- Setup and implementation fees (software licensing, integration with existing systems)

- Ongoing maintenance and support costs

- Transaction-based fees that scale with business volume

- Hidden fees like minimum record lengths that can multiply actual costs

- Compliance charges when integration issues lead to transaction errors

As one industry expert notes, “hard EDI costs have an immediate impact to your bottom line,” yet many organizations fail to account for these expenses until they appear unexpectedly.

Why it happens

This costly oversight typically happens because organizations lack a practical understanding of total EDI costs. Frankly, companies become fixated on attractive initial pricing without examining long-term financial commitments.

In reality, stakeholders often fear investing heavily in EDI networks after experiencing hidden costs with previous software purchases. Yet paradoxically, this caution leads them to underfund critical aspects of integration. Throughout implementation projects, decision-makers focus primarily on upfront costs while neglecting ongoing expenses.

How to avoid it

Firstly, calculate the Total Cost of Ownership (TCO) before committing to any integration strategy. This calculation must include all setup fees, transaction fees, VAN charges, and ongoing support costs.

Secondly, build a 20% buffer into your integration budget for unexpected requirements. In light of how common budget overruns are, this buffer provides essential financial protection.

Above all, understand your business transaction volume and type before selecting pricing schemes. This knowledge helps you negotiate transparent contracts that avoid surprise fees and align with your organization’s actual needs.

Ultimately, by comprehensively assessing all potential costs upfront, you prevent disruptive budget surprises that can derail your entire EDI ERP integration project.

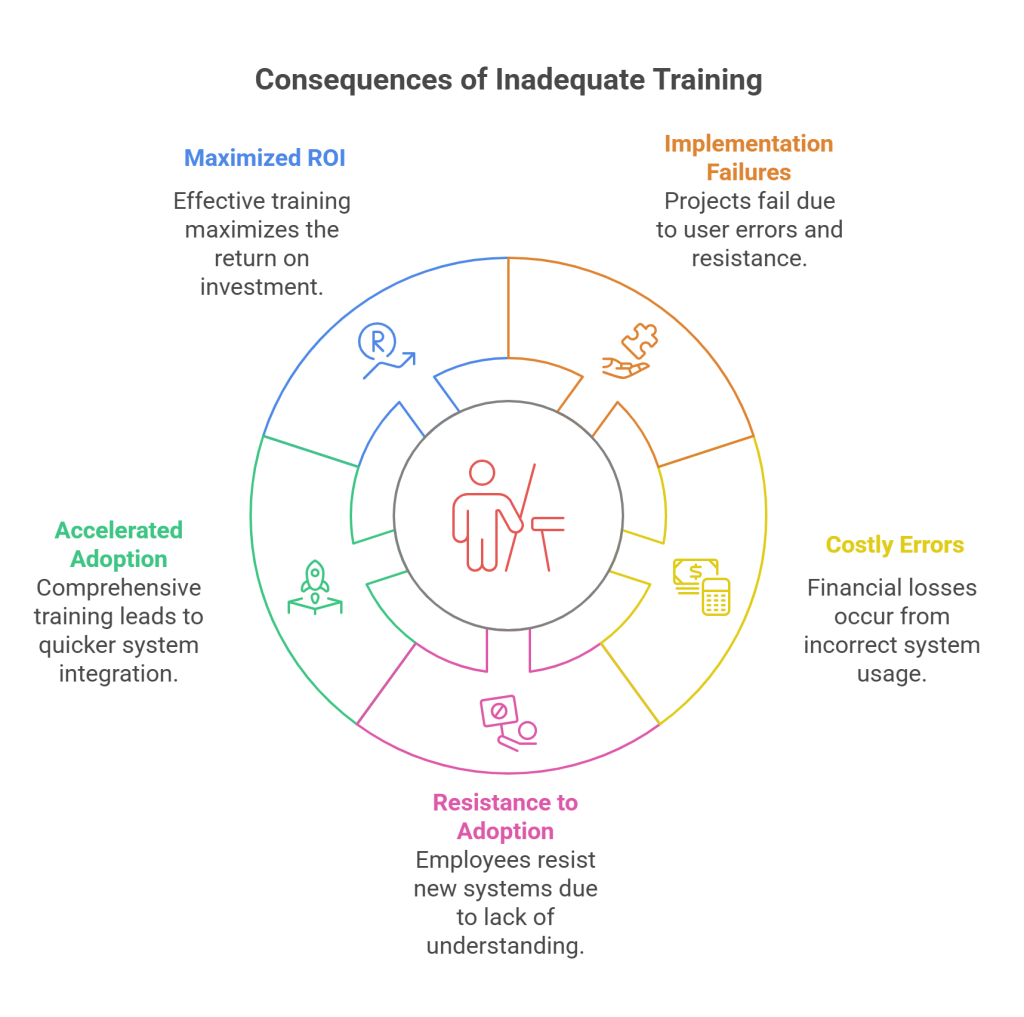

9. Failing to Train Staff on New Systems

Beyond technical considerations, EDI ERP integration success hinges critically on effective user training. Yet many organizations treat training as an afterthought, resulting in costly implementation failures that derail otherwise promising projects.

What is the mistake?

Inadequate staff training manifests as insufficient instruction on new EDI ERP systems, directly undermining implementation success. Studies reveal that between 50%-75% of ERP transformation projects ultimately fail, frequently because end-users incorrectly use systems due to inadequate training. Throughout the integration process, companies often provide minimal instruction that fails to prepare employees for daily operations. As a result, workers struggle with new workflows, make costly errors, and resist adoption altogether.

Why it happens

Organizations shortchange training primarily due to compressed implementation timelines and budget constraints. Many companies underestimate the learning curve associated with complex EDI ERP systems. Frequently, management views training as dispensable when facing time pressures, failing to recognize that skilled users represent the difference between successful adoption and costly failure.

Additional factors include:

- Resistance to change from employees attached to familiar processes

- Training materials that lack depth or relevance to specific job functions

- Insufficient hands-on practice with real-world scenarios

- Inadequate post-training support systems

How to avoid it

To prevent this costly mistake, prioritize training as a cornerstone of your EDI ERP integration strategy. Throughout implementation, secure buy-in from senior management – if leadership doesn’t take training seriously, employees won’t either. Develop clear, measurable learning objectives that align with specific job roles.

Yet perhaps most importantly, implement multi-faceted training approaches that accommodate different learning styles. Focus on practical, interactive exercises that simulate real-world scenarios users will encounter. Additionally, establish robust post-implementation support systems including helpdesks and follow-up training sessions.

By investing adequately in comprehensive training, organizations not only accelerate adoption but also maximize return on their EDI ERP investment.

10. Neglecting Post-Go-Live Monitoring

The post-implementation phase of EDI ERP integration represents a critical blind spot for many organizations that mistakenly view system deployment as the finish line rather than the starting point. Studies suggest that more than half of ERP implementations experience some form of post-deployment disruption due to insufficient monitoring.

What is the mistake?

Neglecting post-go-live monitoring occurs when companies fail to regularly assess system performance after implementation. In essence, organizations treat their EDI ERP systems as static, “set-it-and-forget-it” solutions rather than dynamic environments requiring ongoing attention. This oversight leads to undetected performance degradation, security vulnerabilities, and compliance issues that ripple across departments. Without proper monitoring, businesses miss opportunities to optimize their systems and address emerging challenges before they escalate into costly problems.

Why it happens

This mistake typically stems from misplaced confidence that ERP systems will run themselves once deployed. At this point, implementation teams often disband after go-live, leaving systems without clear ownership for continuous monitoring. In addition to this organizational gap, companies frequently face resource constraints—teams that handled implementation are usually running at capacity with their regular responsibilities. Yet another factor is simple exhaustion; after the intense effort of implementation, teams need breaks before tackling optimization.

How to avoid it

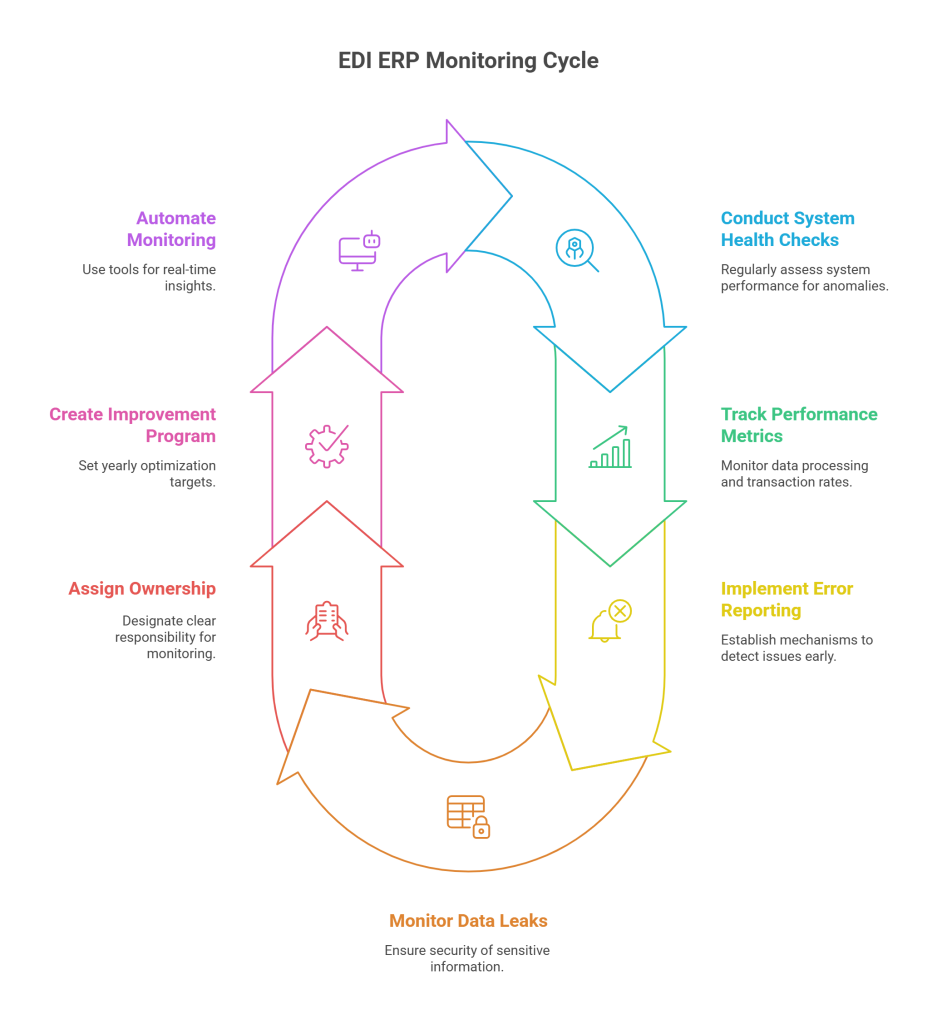

To prevent this costly mistake, implement structured monitoring protocols including:

- Regular system health checks to identify anomalies in the system’s activities

- Tracking performance metrics such as data processing time and transaction completion rates

- Implementing robust error reporting mechanisms to catch issues early

- Conducting data leak monitoring to ensure security of sensitive information

In particular, assign clear ownership for post-implementation monitoring and create a continuous improvement program with yearly optimization targets. Furthermore, build application robots or automated monitoring tools that provide real-time performance insights without manual intervention. By maintaining vigilant oversight of your EDI ERP integration, you’ll protect your investment and maximize its long-term value.

11. Poor Communication with Vendors and Partners

Successful vendor and partner relationships form the backbone of any effective EDI ERP integration, yet many organizations overlook structured communication approaches that could prevent costly failures. Clear communication pathways directly impact system performance, update management, and long-term integration success.

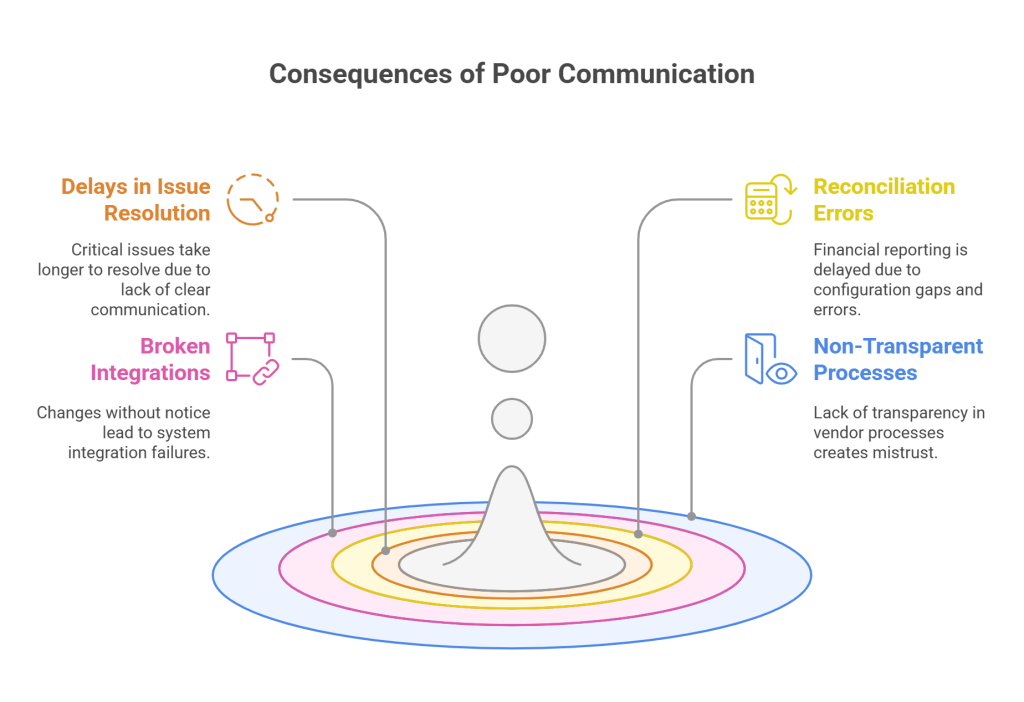

What the mistake is

Poor communication with vendors and partners manifests through undefined escalation processes and inconsistent information exchange. Organizations frequently lack structured feedback loops with their ERP vendors, creating delays when critical issues arise. Without clear accountability, companies struggle to resolve reconciliation errors that stem from configuration gaps, potentially delaying financial reporting. Throughout implementation projects, communication breakdowns often result in broken integrations when vendors deploy changes without adequate notice.

Why it happens

Organizations typically undervalue relationship management, focusing instead on short-term technical goals. This oversight stems from the misconception that vendor relationships require less attention after implementation, whereas the reality demands closer coordination as systems become more deeply integrated. Moreover, power asymmetries between vendors and clients create environments where processes may appear non-transparent or exclusive. Companies sometimes fail to establish appropriate processes for regular stakeholder interaction, limiting active participation from all parties.

How to avoid it

Begin by establishing transparent, open communication channels that include regular updates, feedback loops, and efficient issue resolution pathways. Set clear expectations about project scope, deliverables, timelines, and milestones from the outset. Additionally, implement structured vendor management protocols:

- Develop clear escalation paths for technical issues

- Create consistent communication schedules with vendors

- Establish mutual accountability frameworks where both parties share responsibility for success

Remember that factors such as responsive support teams and trustworthiness should be evaluated during the vendor selection process. As one expert notes, “When you need to report a problem, who do you reach out to? Your ERP provider should offer a support team that communicates effectively and responds to issues efficiently”.

Conclusion

The financial and operational consequences of EDI ERP integration failures clearly extend far beyond initial implementation costs. Throughout this article, we’ve explored eleven critical mistakes that routinely derail integration projects and cost companies millions. These mistakes – from unclear objectives and excessive customization to inadequate training and poor monitoring – represent significant yet avoidable pitfalls in the integration journey.

Undoubtedly, successful integration requires careful planning, appropriate resource allocation, and continuous attention to both technical and human factors. Companies that avoid these mistakes typically experience substantial benefits: streamlined operations, reduced errors, improved data visibility, and significant cost savings. Conversely, organizations that rush into integration without proper preparation often face budget overruns, implementation delays, and frustrated end-users.

How Commport Can Help With EDI ERP Integration and Also Offer Custom Integration Solutions. Commport Communications stands as a valuable resource for companies seeking to navigate these complex challenges while avoiding costly missteps. Their specialized expertise in both EDI systems and ERP integration provides the guidance many organizations need.

Finally, remember that EDI ERP integration represents an ongoing journey rather than a one-time project. Systems, requirements, and trading partner needs will evolve, demanding regular assessment and optimization. Though implementing best practices might initially seem overwhelming, taking a methodical approach—addressing one area at a time—significantly increases your chances of success. Subsequently, your integration efforts will deliver the operational efficiency and competitive advantage your business needs in today’s complex supply chain environment.

Commport EDI ERP Integrations

Need Help? Download: Commport's EDI Buyers Guide

Unlock the full potential of your supply chain with our comprehensive EDI Buyer's Guide — your first step towards seamless, efficient, and error-free transactions

Frequently Asked Questions

The most common mistakes include lack of clear integration objectives, over-customizing the ERP system, inadequate data migration planning, relying on manual processes, and using built-in EDI tools without proper evaluation. These errors can lead to project failures, budget overruns, and operational inefficiencies.

Companies should calculate the Total Cost of Ownership (TCO) before committing to any integration strategy. This should include all setup fees, transaction fees, ongoing support costs, and a 20% buffer for unexpected requirements. Understanding business transaction volume and type is crucial for selecting appropriate pricing schemes and avoiding surprise fees.

End-to-end testing is vital because it verifies that EDI documents flow correctly between organizations and internal systems before actual implementation. Skipping this step can lead to critical issues being discovered only after going live, resulting in internal chaos, supply chain disruptions, and financial data inconsistencies.

Staff training is crucial for EDI ERP integration success. Inadequate training can lead to employees struggling with new workflows, making costly errors, and resisting adoption. Organizations should prioritize comprehensive training approaches that accommodate different learning styles and include practical, interactive exercises simulating real-world scenarios.

Post-go-live monitoring is essential for maintaining system performance and addressing emerging challenges. Regular system health checks, performance metric tracking, and error reporting mechanisms help identify and resolve issues early. Assigning clear ownership for post-implementation monitoring and creating a continuous improvement program are key to protecting the integration investment.