Introduction

Supply chain visibility has become a critical factor for businesses seeking to prevent costly disruptions in today’s complex global marketplace.

More than 80% of the typical consumer company’s greenhouse gas emissions are embedded in their supply chains, highlighting just one area where improved transparency delivers significant value.

When we discuss supply chain visibility, we refer to the ability to track, monitor, and comprehend all activities within your supply chain. This transparency allows organizations to gain advanced insights into operations while simultaneously reducing risk.

Furthermore, the importance of supply chain visibility has skyrocketed in recent years as businesses face increasing pressure to comply with environmental, social, and corporate governance (ESG) regulations.

The benefits of enhanced visibility extend far beyond compliance. Better visibility into complex supply chains ultimately translates to fewer disruptions, increased customer satisfaction, and lower costs.

Additionally, when we can identify potential disruptions before they occur, the chances of them causing problems are significantly reduced.

In this blog, we’ll explore

What does supply chain visibility truly mean,

why it matters more than ever in today’s global market, and

provides simple, actionable steps to improve visibility across your operations.

Whether you’re just beginning to address visibility challenges or looking to enhance your existing capabilities, this article will help you navigate the path forward.

What is Supply Chain Visibility?

The backbone of modern supply management lies in its ability to be fully observable. Supply chain visibility (SCV) refers to the ability to track components, sub-assemblies, and final products as they travel from supplier to manufacturer to consumer. Essentially, it’s a strategic capability that allows businesses to monitor every element of their supply chain from end to end.

Definition and scope of SCV

Supply chain visibility encompasses the complete, real-time view of a company’s logistics, inventory, and warehouse management processes. Rather than simply knowing where items are located, comprehensive SCV provides insights into inventory levels, shipment status, production schedules, and warehouse operations.

The scope of SCV typically includes multiple dimensions:

- Order Visibility: Tracking customer orders from placement to fulfillment

- Inventory Visibility: Monitoring stock levels across locations

- Shipment Visibility: Following goods during transport

- Production Visibility: Overseeing manufacturing processes

Advanced SCV systems enable total visibility into inventory on the move—from air freight and shipping cargo down to the exact bin level in warehouses. This holistic approach covers the entire journey from raw material source to final delivery, offering a comprehensive view of the complete supply network.

How SCV Differs from Traditional Supply Chain Tracking

Traditional tracking forms the foundation upon which the sophisticated architecture of visibility is built. However, several key differences separate modern SCV from conventional tracking approaches:

First, traditional tracking typically relies on delayed or manual updates through paper-based records, phone calls, or emails. In contrast, SCV provides continuous, real-time data across every stage of the supply chain, allowing for immediate identification of disruptions.

Second, whereas traditional systems often focus on specific segments of the supply chain (like warehouses or transportation hubs), SCV offers comprehensive, end-to-end transparency. This means nothing falls through the cracks between different operational stages.

Third, traditional tracking is primarily reactive, responding to issues after they arise. Conversely, modern SCV employs predictive analytics through AI and machine learning to forecast potential disruptions before they occur.

Finally, traditional methods typically operate as standalone systems, lacking integration with other business tools. Modern SCV solutions seamlessly integrate with enterprise systems, IoT devices, and logistics automation.

Why Supply Chain Visibility Matters More Than Ever

In today’s interconnected business landscape, the value of clear supply chain insights has never been greater. As global networks grow increasingly complex, companies that prioritize visibility gain significant advantages over competitors.

Impact On Customer Satisfaction and Trust

When products aren’t available, businesses face both immediate revenue loss and risk to future sales as consumers look elsewhere. Indeed, a recent study revealed that 80% of customers consider supply chain transparency a key factor in their purchasing decisions.

Businesses with enhanced visibility experience up to a 15% improvement in order fulfillment accuracy, directly impacting on customer satisfaction. This transparency builds deeper relationships with buyers who appreciate being informed about their order status from entry to delivery.

Notably, investing in supply chain visibility consistently strengthens consumer trust. Companies that demonstrate transparent practices not only meet customer expectations but also foster long-term loyalty through reliable service and accurate delivery estimates.

Role in Risk Reduction and Disruption Prevention

Early identification of potential risks enables proactive measures before issues escalate. Real-time data empowers businesses to detect disruptions based on historical patterns and external factors such as geopolitical events or weather forecasts.

Companies can leverage this visibility to implement stronger cybersecurity protocols, particularly important as supply chains become more digitalized and interconnected. According to Gartner, by 2027, 17% of total cyberattacks will involve generative AI, making proactive risk management essential.

Importance of supply chain visibility in global operations

IDC’s 2022 Supply Chain Survey found 80% of respondents had projects underway to improve supply chain visibility. This surge reflects how volatile markets, unstable geopolitics, and evolving regulations are driving change in global supply networks.

Above all, visibility supports compliance with international regulations while meeting growing consumer demands for responsible sourcing. Material flow visibility combines supplier network data with procurement information, supporting initiatives like ESG compliance and risk scoring.

Commport B2B network solutions help you streamline your supply chain operations and improve efficiency. Our solutions include EDI, VAN, GDSN, PIM, and Business Analytics.

Consequently, businesses that master visibility gain the intelligence and agility needed to navigate market uncertainties and prevent costly disruptions.

Common Barriers to Achieving Real-Time Supply Chain Visibility

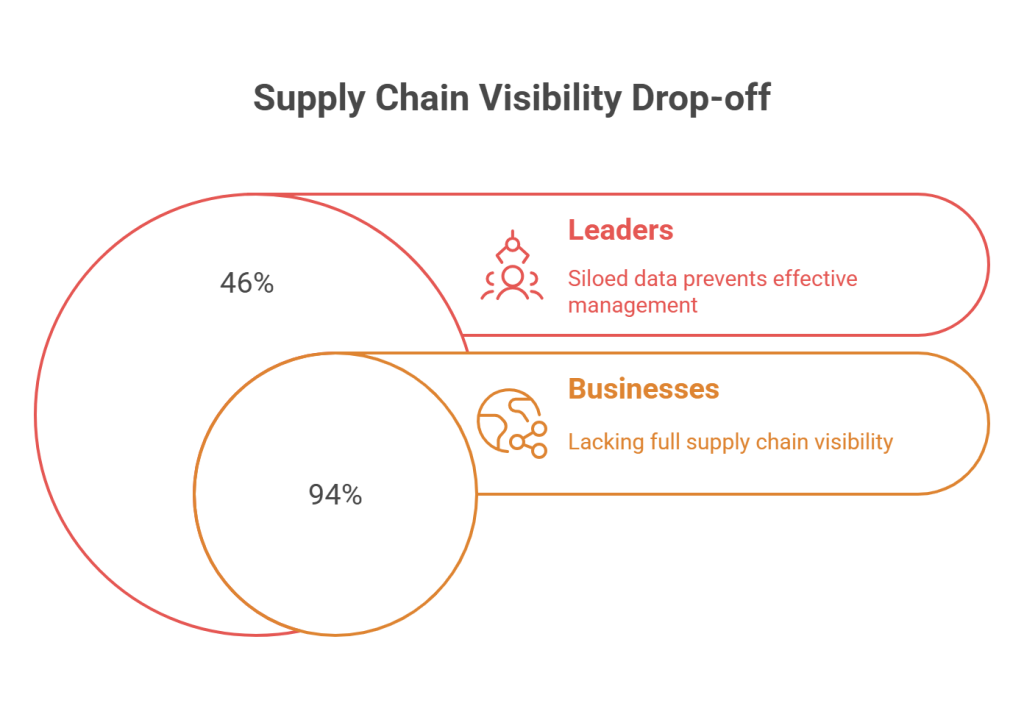

Despite widespread recognition of its value, achieving real-time supply chain visibility remains elusive for many organizations. A striking 94% of businesses do not have full visibility of their supply chain and logistics operations. Let’s examine the major obstacles preventing companies from gaining the transparency they need.

1. Data Silos and Lack of Integration

Data fragmentation represents perhaps the most significant barrier to supply chain visibility. Nearly half (46%) of supply chain leaders report that siloed data and teams prevent them from establishing processes to manage their supply chains effectively. This challenge typically manifests as:

- Disparate systems that don’t communicate (WMS, TMS, OMS, 3PL systems)

- Inconsistent data formats across partners

- Legacy IT systems operating in isolation

- Lack of standardized communication protocols

These silos create information gaps that make it impossible to gain a holistic view of operations, leading to misaligned processes and delayed decision-making.

2. Limited Collaboration Across Partners

Trust issues present major hurdles in achieving visibility across supply networks. Many organizations struggle with concerns over data accuracy and hesitate to share sensitive information with partners. This lack of collaboration in data sharing means companies cannot access critical information that exists outside their organization, limiting analytical capabilities and strategic decision-making.

3. High Cost of Technology Implementation

For many businesses, the expenses associated with implementing advanced visibility solutions present significant obstacles. Beyond the initial investment, companies struggle to balance technology costs against business benefits. The challenge intensifies when integrating modern solutions with legacy systems that use outdated communication protocols and have limited API support.

4. Resistance to Change Within Organizations

Organizational mindset forms the final barrier to achieving visibility. Companies often face internal resistance when adopting new technologies. The fear of disrupting existing processes can slow down the implementation of solutions that could improve visibility. Moreover, limited technical knowledge and inadequate training for working with advanced technologies make data sharing more difficult, further hampering transparency efforts.

Conclusion

Supply chain visibility stands as a cornerstone of modern business operations. Throughout this guide, we’ve examined how comprehensive visibility transforms supply networks from potential vulnerability points into strategic advantages.

First and foremost, enhanced visibility directly correlates with customer satisfaction. Customers undoubtedly expect transparency—with 80% considering it a key factor in purchasing decisions. Companies that deliver this transparency build trust and foster loyalty that withstands market fluctuations.

Additionally, real-time supply chain visibility serves as a powerful risk management tool. Early identification of potential disruptions allows proactive intervention before problems escalate into costly failures. This preventative approach proves especially valuable as supply chains face increasing threats from cyber attacks, geopolitical tensions, and climate events.

Despite these clear benefits, many organizations still struggle with implementation barriers. Data silos, partner collaboration challenges, technology costs, and organizational resistance create significant hurdles. Nevertheless, these obstacles can be overcome through systematic planning and execution.

The six-step approach outlined—mapping your supply chain, investing in tracking tools, integrating systems, training teams, applying predictive analytics, and continuous monitoring—provides a practical roadmap for progress. Companies following these steps consistently report fewer disruptions, lower costs, and higher customer satisfaction.

Supply chain visibility ultimately represents more than just knowing where products are located. Rather, it embodies a strategic capability that supports informed decision-making across your entire operation. Organizations that prioritize visibility gain not only operational efficiency but also competitive advantage in increasingly complex markets.

The journey toward complete supply chain visibility requires commitment and investment. However, the alternative—continuing to operate with limited transparency—carries far greater costs through disruptions, lost customers, and missed opportunities. Businesses that embrace visibility today position themselves to thrive amid whatever challenges tomorrow brings.

Commport B2B Solutions

Frequently Asked Questions

Supply chain visibility refers to the ability to track and monitor all activities within your supply chain, from raw material sourcing to final product delivery. It provides real-time insights into inventory levels, shipment statuses, production schedules, and warehouse operations, enabling businesses to make informed decisions and respond quickly to potential disruptions.

Supply chain visibility is essential because it directly impacts customer satisfaction, risk reduction, and operational efficiency. It allows businesses to prevent costly disruptions, improve order fulfillment accuracy, and build trust with customers. In today’s complex global marketplace, visibility also helps companies comply with regulations and meet growing demands for responsible sourcing.

The primary barriers include data silos and lack of integration between systems, limited collaboration across partners, high costs of implementing new technologies, and resistance to change within organizations. These challenges often result in fragmented information and difficulty in gaining a holistic view of operations.

Companies can enhance visibility by mapping their entire supply chain, investing in real-time tracking tools, integrating data across systems, training teams on visibility tools, using predictive analytics for forecasting, and continuously monitoring and adjusting their processes. These steps help create a more transparent and efficient supply network.

Implementing supply chain visibility can lead to reduced out-of-stock inventory, improved perfect order delivery, fewer disruptions, lower costs, and higher customer satisfaction. It also enables businesses to identify potential risks early, make data-driven decisions, and gain a competitive advantage in increasingly complex markets.