Introduction

With about 2 million users worldwide and more than 6 billion daily transactions powered by GS1 barcodes, food traceability systems are transforming how businesses operate. Effective food safety traceability doesn’t just prevent recalls—it creates measurable business value. For example, IPC/Subway saved an estimated $1.3 million annually by aligning its master data with GS1 Standards, while also reducing its inventory process from several hours to just minutes.

Furthermore, the impact extends across the entire supply chain. Warehouse operators experience 21% shorter lead times when using GS1 food safety traceability standards, while more than half of the produce industry has already implemented traceability processes utilizing these standards. Additionally, when recalls do occur, GS1 Standards help “identify where the products came from, where they went, and get them under control faster”.

Key Takeaways

- GS1 standards deliver proven ROI: Companies like IPC/Subway save $1.3 million annually while reducing inventory processing from hours to minutes through standardized traceability systems.

- Three core identifiers enable end-to-end tracking: GTINs for products, GLNs for locations, and SSCCs for logistics units create a unified language connecting every supply chain stakeholder.

- GDSN synchronization eliminates data silos: Real-time product updates through the Global Data Synchronization Network reduce order errors and accelerate time-to-market for food processors.

- Recall readiness protects brands and consumers: Standardized traceability enables rapid identification and removal of contaminated products, crucial when 7% of the global population experiences foodborne illness annually.

- 2D barcodes build consumer trust through transparency: QR codes and DataMatrix barcodes provide instant access to ingredient lists, allergen information, and product journey data, meeting modern transparency demands.

How GS1 Standards Enable Food Traceability at the Source

Define Food Traceability

Food traceability refers to the ability to track the movement of food products and their ingredients throughout every stage of the supply chain—from production and processing to packaging, distribution, and final consumption.

It involves collecting and maintaining detailed information about the origin, handling, and journey of a food item. This ensures that each product can be traced backward (to its source) and forward (to its destination) at any point in the supply chain.

Key aspects of food traceability include:

- Source identification – Knowing where raw materials and ingredients came from (farm, supplier, or processor).

- Batch/lot tracking – Assigning codes to monitor specific product batches for quality and safety.

- Supply chain transparency – Recording how food is stored, transported, and handled.

- Recall management – Quickly identifying and removing unsafe or contaminated products from the market.

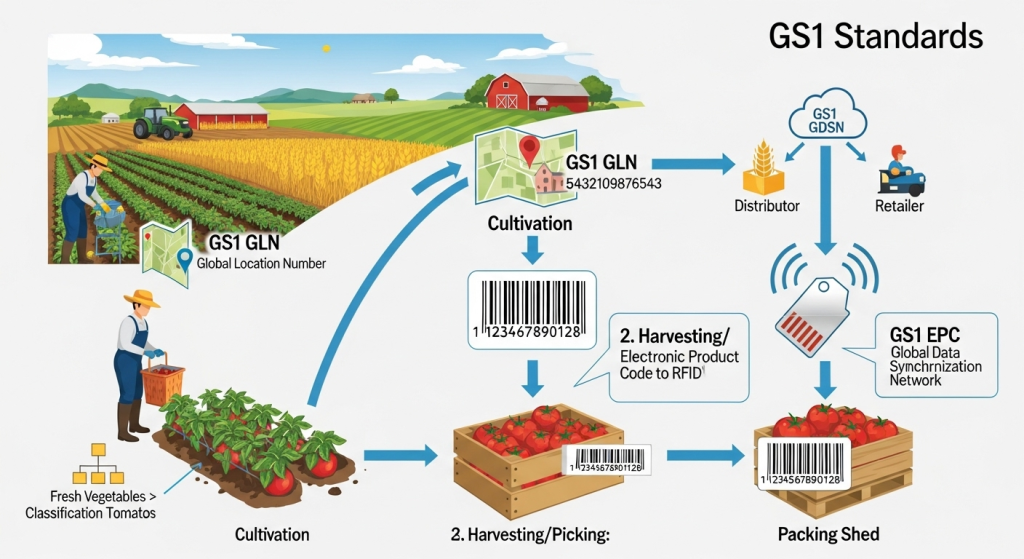

Tracking food products effectively begins at the source, where GS1 standards function as the DNA of items moving through the value chain. These globally unique product identifiers form the foundation for effective traceability systems by providing a common language for supply chain partners.,

1. GTIN Assignment for Raw Materials

Global Trade Item Numbers (GTINs) serve as 14-digit identifiers for products exchanged in the supply chain. Raw material manufacturers and food processors use GTINs as a global standard in their transactions, primarily for items traded between these parties. The structured format includes:

- Indicator digit

- GS1 Company Prefix

- Item Reference Number

- Check Digit

Raw materials carrying standardized barcodes enable quick information verification and system import, consequently reducing human error and confusion during inspection. Different-sized trade items must have different GTINs, as must items with new specifications or from different suppliers.

2. GLN Usage for Farm and Facility Identification

Global Location Numbers (GLNs) are 13-digit identifiers that pinpoint physical locations with precision. Indeed, each GLN corresponds to one precise location in the world. These identifiers can represent:

- Legal entities (parent corporations, subsidiaries)

- Functional entities (departments)

- Physical locations (manufacturing plants, distribution centers)

For farming operations, GLNs help identify critical tracking locations, including packing sheds, warehouses, distribution centers, farms, and fields. Farm maps must show the location and name of each field or growing area, creating a comprehensive location framework for traceability.

3. SSCC for Logistics Unit Tracking

The Serial Shipping Container Code (SSCC) functions as an 18-digit “license plate” for logistics units. This identifier tracks individual logistic units—whether pallets, cases, or shipping containers—throughout the supply chain.

SSCCs provide unique benefits:

- Enable tracking of individual logistic units

- Allow reliable lookup of complex load details

- Facilitate speedy receiving and reconciliation processes

- Identify contents when used with the Advance Ship Notice (ASN)

The SSCC’s structure includes an Extension Digit, GS1 Company Prefix, Serial Reference, and Check Digit. It remains the single mandatory element for all logistic shipping labels, essentially ensuring that each shipping unit maintains its unique identity worldwide.

These three foundational elements—GTINs, GLNs, and SSCCs—work together to create a standardized framework that enables cost-effective traceability for every product across every supply chain.

Labeling and Data Synchronization in Food Processing

Once raw materials reach processing facilities, proper labeling and synchronized data become critical links in the food traceability chain. Processing represents a key transformation point where accurate product information must follow items throughout their journey.

1. GS1-128 Barcode for Batch and Lot Encoding

The GS1-128 barcode serves as a powerful data carrier specifically designed for cases and pallets not intended for retail point-of-sale scanning. Unlike basic product codes, these advanced barcodes can encode up to 48 characters of vital information. Through Application Identifiers (AIs), processors can include:

- AI (01) for Global Trade Item Number (GTIN)

- AI (10) for batch/lot numbers

- AI (11) for production dates

This encoding enables a single scan to capture detailed product history, making the GS1-128 essential for shipping, receiving, and warehouse operations.

2. GDSN Integration for Real-Time Product Updates

The Global Data Synchronization Network (GDSN) functions as an online framework following GS1 standards that connects trading partners across the supply chain. It creates a single source of truth for product information, particularly vital for food processors managing complex data like ingredients, nutrition facts, allergens, and packaging details.

Commport GDSN Datapool – GS1 certified GDSN datapool solutions trusted by 3000+ brands globally. Centralize, enrich, and synchronize all your product data to multiple marketplaces and trading partners in one click!

With GDSN, data updates flow instantly through secure databases, eliminating manual re-entry and reducing order errors. This real-time synchronization significantly enhances inventory accuracy and accelerates time-to-market.

3. FSMA Rule 204 Compliance through Structured Data

The Food Safety Modernization Act (FSMA) Rule 204 establishes comprehensive traceability recordkeeping requirements. Published in 2023 with a compliance deadline set for January 2026, this regulation necessitates structured data management.

GS1 standards provide the foundation for meeting these requirements by standardizing product and location identification throughout the supply chain. Through proper implementation, companies can efficiently prepare for regulatory compliance while simultaneously improving their traceability capabilities.

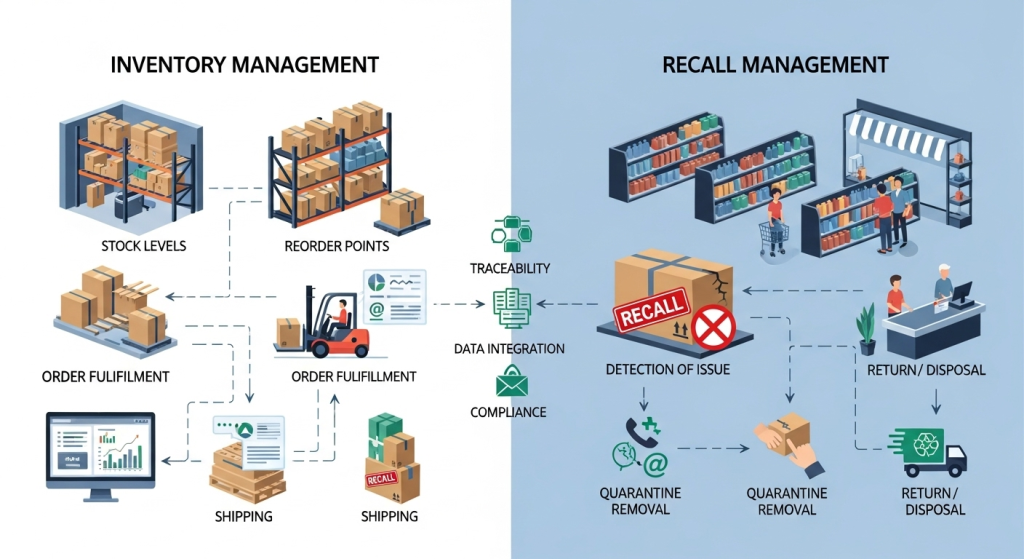

Inventory and Recall Management in Distribution and Retail

Distribution centers and retail stores represent critical control points in the food supply chain where proper inventory management directly impacts both operational efficiency and recall readiness.

1. Advance Ship Notice (ASN) and Order Accuracy

Advance Ship Notices serve as electronic documents sent from suppliers to buyers before shipment arrival, containing detailed information about incoming orders. These notices typically include:

- Order number and shipment details

- GTIN, batch/lot numbers, and quantities

- Logistics information, including SSCC codes

- Expected delivery dates and times

ASNs dramatically improve receiving efficiency, reducing costs by approximately 40%. Moreover, they enable buyers to verify order accuracy before shipment arrival, allowing time to address shortages through alternative sourcing. ASNs thus create an electronic paper trail that minimizes disputes between trading partners.

2. Automated Inventory Rotation Using GTIN and SSCC

GTINs and SSCCs function as cornerstones for effective inventory management at distribution and retail levels. These standards facilitate:

- Receipt verification and product put-away

- Inventory rotation based on production dates

- Quality control processes

- Automated shipment creation

This standardized approach ensures first-in, first-out inventory management, minimizing waste while maintaining product freshness and safety throughout the supply chain.

3. Recall Readiness with Location-Based Traceability

Recalls remain inevitable in the food industry—making preparedness essential. Each year, over 7% of the global population experiences foodborne illnesses, resulting in 420,000 deaths annually.

GS1 standards enable rapid response through location-based traceability that allows companies to:

- Determine contamination sources quickly

- Isolate affected products precisely

- Communicate effectively with regulatory agencies

- Execute withdrawal plans efficiently

FDA guidance emphasizes being “recall ready,” requiring companies to establish teams, identify problems, determine recall scope, and develop comprehensive communications strategies. Therefore, structured traceability data becomes fundamental to protecting both public health and brand reputation.

Building Consumer Trust Through Transparency and Access

Transparency has increasingly become a decisive factor in consumer purchasing decisions, with GS1 standards providing the foundation for accessible product information.

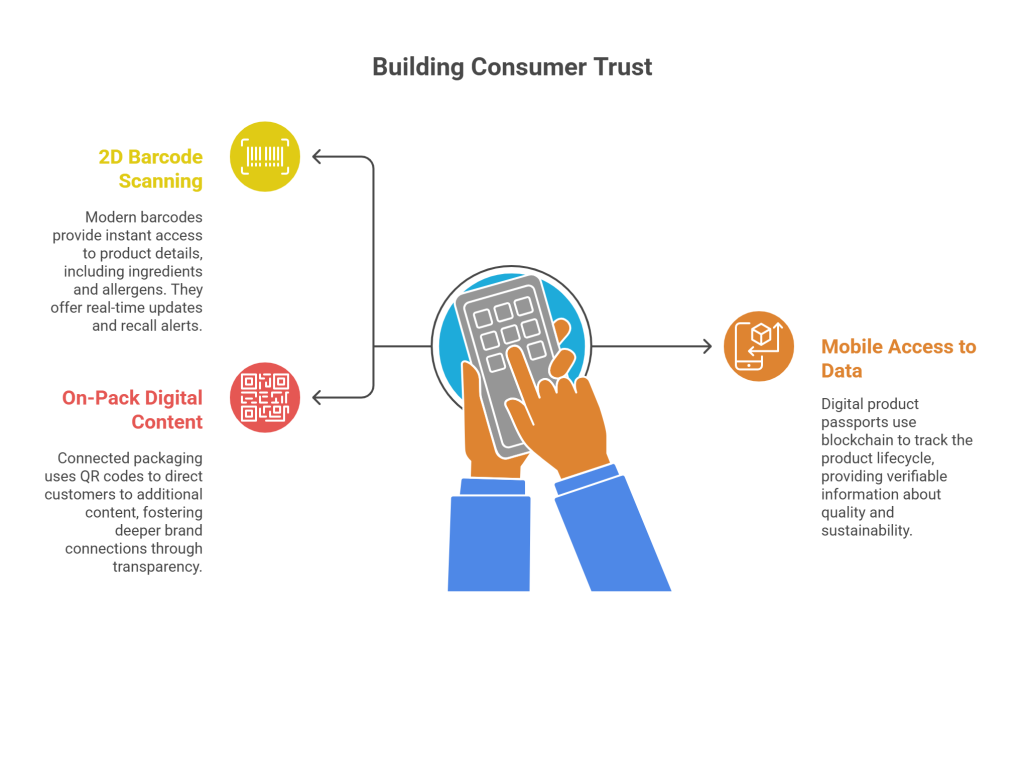

1. 2D Barcode Scanning for Ingredient and Allergen Info

Modern 2D barcodes, such as QR Codes and GS1 DataMatrix, store significantly more data than traditional 1D barcodes, enabling instant access to comprehensive product details. These barcodes store GTINs alongside critical information, including expiration dates and serial numbers. Due to their data capacity, they offer real-time ingredient lists, allergen disclosures, expiration dates, batch numbers, and potential recall alerts. Apart from regulatory compliance, this capability allows brands to update ingredient information instantly without costly packaging reprints.

2. Mobile Access to Product Journey and Sustainability Data

Digital product passports, powered by blockchain technology, allow consumers to track the entire product lifecycle. By scanning a style tag via mobile app, shoppers gain access to the product’s journey—from material origin through manufacturing to distribution. This transparency builds trust by providing verifiable information about product quality, origin, and sustainability practices.

3. Consumer Engagement via On-Pack Digital Content

On-pack digital elements transform static packaging into interactive experiences. Currently, connected packaging embeds technologies like QR codes that direct customers to additional content such as product information, instructional videos, and brand storytelling. Ultimately, this approach satisfies the modern consumer’s demand for information while fostering deeper brand connections through transparency.

Conclusion

Food traceability systems powered by GS1 standards have transformed modern food supply chains. Throughout this article, we explored how these standards create a common language that connects every stakeholder from farm to fork. GTINs, GLNs, and SSCCs work together as foundational elements that enable precise tracking of products, locations, and logistics units across the entire supply chain.

Business benefits extend far beyond regulatory compliance. Companies like IPC/Subway demonstrated substantial cost savings—approximately $1.3 million annually—while significantly reducing inventory processing time. Warehouse operators likewise experienced 21% shorter lead times when implementing these standards, proving their operational value.

Recall management stands out as a critical advantage of standardized traceability systems. During food safety incidents, GS1 standards help companies quickly identify affected products, determine their location, and remove them from circulation. This rapid response capability protects both consumers and brand reputation during crises.

Advanced technologies like 2D barcodes and digital product passports further enhance traceability efforts. These tools provide consumers with unprecedented access to product information, supporting allergen awareness and enabling verification of sustainability claims. Consequently, brands that embrace transparency build stronger relationships with increasingly informed consumers.

FSMA Rule 204 compliance will soon become mandatory, making now the perfect time for food businesses to implement robust traceability systems. GS1 standards and GDSN provide the framework needed to meet these requirements while simultaneously improving operational efficiency.

Undoubtedly, food traceability represents more than just a regulatory obligation—it has become a business imperative. Companies that embrace these technologies create safer food systems, build consumer trust, and position themselves competitively in an industry where transparency increasingly drives purchasing decisions.

Commport GS1 Certified GDSN Datapool

Download: GDSN Buyers Guide

Empower your business with global data synchronization; download our GDSN Buyer's Guide today and take the first step towards streamlined, accurate, and compliant product data management.

Frequently Asked Questions

GDSN (Global Data Synchronization Network) is an internet-based network that allows companies to exchange standardized product data with their trading partners. It operates using GS1 standards, creating a single source of truth for product information and enabling real-time updates across the supply chain.

GS1 standards provide a common language for supply chain partners, enabling end-to-end traceability. They use unique identifiers like GTINs for products, GLNs for locations, and SSCCs for logistics units. This standardization allows for quick identification of product sources, precise tracking, and efficient recall management, ultimately enhancing food safety.

Implementing GS1 standards can lead to significant cost savings and operational efficiencies. For example, some companies have reported annual savings of over $1 million and reduced inventory processing times. Additionally, these standards improve order accuracy, reduce lead times, and enhance overall supply chain visibility.

2D barcodes, such as QR codes and GS1 DataMatrix, can store more information than traditional barcodes. When scanned, they provide consumers with instant access to detailed product information, including ingredients, allergens, expiration dates, and even the product’s journey through the supply chain. This transparency helps build consumer trust and meets the growing demand for product information.

FSMA Rule 204 is a regulation that establishes comprehensive traceability recordkeeping requirements for the food industry, with compliance required by January 2026. GS1 standards provide the foundation for meeting these requirements by standardizing product and location identification throughout the supply chain, helping companies efficiently prepare for regulatory compliance while improving their traceability capabilities.