Introduction

GS1-128, a globally recognized labeling standard, plays a vital role in streamlining supply chains. It enables accurate tracking and identification of products, facilitating smooth logistics operations and inventory management. In this blog, we will delve into the details of GS1-128 labels, their technical aspects, applications, and the benefits they offer to businesses.

What is the GS1-128 Label?

GS1-128, formerly known as UCC/EAN-128, is a barcode symbology that belongs to the GS1 System. GS1 is a not-for-profit organization that develops and maintains global standards for supply chain management, including product identification, data capture, and communication. The GS1-128 label is based on Code 128, a high-density, variable-length, and continuous barcode standard used to encode alphanumeric data.

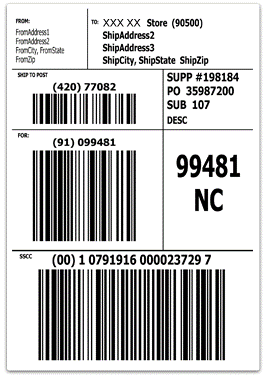

GS1-128 shipping labels enable carton visibility throughout the supply chain. A GS1-128 shipping label is commonly broken down into various pre-defined zones. Each zone normally contains either text or barcode information. The bottom zone (Zone I) is commonly used to host the SSCC-18 barcode, tied to an EDI document referencing all the carton contents.

Suppliers to the retail industry are challenged by specific zone requirements for each of their trading partners. In addition to utilizing the SSCC-18 barcode, many retailers use a Store (or Destination) barcode in Zone G. By the GS1 General Specifications, all the barcodes on this label should be GS1-128 symbols.

An Application Identifier is used to specify the data format and purpose for each zone of different companies. GS1-128 not only encodes the data but provides a method of defining the meaning of the data by defining a list of “Application Identifiers” (AI’s).

GS1-128 Label Technical Details

The GS1-128 label is designed to carry essential information about a product or shipment. It uses Application Identifiers (AIs) to define data elements within the barcode. Each AI specifies the type of data it represents, such as batch/lot number, expiration date, serial number, etc. The AI is followed by the data itself, and multiple AIs can be combined to create a comprehensive label.

The structure of GS1-128 is as follows:

- Start Code: Indicates the beginning of the barcode.

- Application Identifier (AI): Defines the data element.

- Data: The specific information related to AI.

- Check Character: Ensures the barcode’s accuracy and integrity.

- Stop Code: Marks the end of the barcode.

How GS1-128 Label Used?

GS1-128 labels find widespread use in various industries, including retail, healthcare, logistics, and manufacturing. Some common applications include:

1. Product Identification

GS1-128 enables a unique identification of products and items within a supply chain, reducing errors and enhancing traceability.

2. Shipping and Logistics

The label is used to encode information about shipments, such as product details, quantities, and destination, simplifying logistics processes.

3. Inventory Management

GS1-128 labels aid in efficient inventory tracking, allowing businesses to optimize stock levels and minimize stockouts.

4. Traceability and Recall Management

In case of product recalls or quality issues, the encoded data helps identify affected batches quickly, aiding in timely recalls and reducing potential risks.

Benefits of GS1-128 Label

The adoption of GS1-128 labels brings several advantages for businesses and the entire supply chain:

1. Enhanced Efficiency

The standardized format streamlines operations, leading to faster processes and reduced errors.

2. Improved Traceability

GS1-128 enables end-to-end traceability, which is crucial for compliance, quality control, and supply chain visibility.

3. Accurate Inventory Management

Businesses can maintain optimal stock levels, reducing carrying costs and improving order fulfillment.

4. Global Acceptance

GS1-128 is an internationally recognized standard, ensuring compatibility and acceptance across different regions and industries.

5. Cost Savings

By minimizing errors, automating processes, and preventing stockouts, businesses can save on operational costs.

Common Challenges With the GS1 128 Barcode Label

Despite its widespread adoption, the GS1-128 barcode label system presents challenges, especially when navigating the unique requirements imposed by individual retailers. Any deviation from these specifications can result in costly chargebacks, making meticulous compliance crucial.

1. Varied Retailer Requirements

Every retailer establishes distinct GS1-128 label specifications, creating a complex landscape of varied requirements. Managing these diverse demands can be challenging for businesses.

2. Potential for Costly Chargebacks

The stringent adherence to retailer-specific GS1-128 label standards is paramount. Deviations may trigger chargebacks, impacting financial stability and eroding profits.

3. Complex Retail Compliance Management:

Staying abreast of ever-evolving retail requirements can be a cumbersome task. The dynamic nature of these standards demands constant vigilance to ensure ongoing compliance.

The successful implementation of GS1-128 labels lies in understanding your unique business needs and integrating them effectively into your supply chain processes. With this standardized labeling system, businesses can gain a competitive edge and build stronger relationships with trading partners and customers alike.

Conclusion

The GS1-128 label is a powerful tool for efficient supply chain management, enabling accurate product identification, streamlined logistics, and enhanced traceability. Its standardized format and global acceptance make it an indispensable component of modern supply chains, benefiting businesses and consumers alike. Embracing GS1-128 not only improves operational efficiency but also fosters trust and reliability in the global marketplace.

How a Full-Service EDI Provider like Commport Can Help in Generating GS1 128 Labels?

Download: EDI Buyers Guide

Unlock the full potential of your supply chain with our comprehensive EDI Buyer's Guide — your first step towards seamless, efficient, and error-free transactions

Frequently Asked Questions

GS1-128 is part of the GS1 System, which sets it apart with its globally recognized standards. Unlike traditional barcodes that may carry limited information, GS1-128 can encode various data elements using Application Identifiers, making it versatile for supply chain applications.

While GS1 membership is not mandatory to use GS1-128 labels, obtaining GS1 identification numbers for your products is recommended for ensuring uniqueness and compliance with GS1 standards

Yes, GS1-128 is scalable and can be used by businesses of all sizes. It offers the same benefits of efficiency and traceability to small businesses as it does to larger enterprises.

Yes, GS1-128 labels are designed for seamless integration with Electronic Data Interchange (EDI) and various software systems, making data exchange and processing efficient and accurate.

Absolutely, GS1-128 labels have diverse applications across industries such as healthcare, automotive, and aerospace, where accurate identification and tracking are critical.

No, GS1 has developed other barcode standards as well, each serving specific purposes. GS1-128 is one of the most widely used standards, particularly for supply chain management and logistics.

GS1-128 labels can be printed on a variety of materials, including paper and synthetic materials, depending on the specific requirements of the product and environment.