Introduction

A single replacement part can shut down an entire production line for months until it’s received. This is where mastering lean and JIT strategies becomes crucial for modern businesses.

Just-in-Time inventory management is a methodology focused on eliminating non-value-added activities. The core principle is simple: produce and deliver only what is needed, in the exact quantity, and at the right time. When implemented with real-time data, JIT can reduce inventory waste while boosting customer satisfaction and creating brand loyalty.

Furthermore, lean manufacturing and JIT work together to create more efficient production processes. By diversifying their supplier base, companies can reduce dependence on a single supplier, which helps mitigate the risk of supplier bankruptcy, production delays, or quality issues.

In this step-by-step guide, we’ll show you how to implement these powerful methodologies to manage supply chain risk effectively. From understanding the fundamental principles to building resilience through strategic planning, you’ll learn practical ways to apply lean and JIT concepts to your operations.

Let’s dive into how you can transform your supply chain with these proven strategies!

Key Takeaways

- Implement strategic supplier diversification using a “supplier +1” approach to prevent single points of failure while maintaining JIT efficiency

- Create smart inventory buffers by applying JIT to stable items and maintaining safety stock for high-risk components without overstocking

- Use Value Stream Mapping (VSM) to identify 80-90% of wasteful activities in your processes and eliminate bottlenecks that create vulnerabilities

- Deploy lean tools systematically– 5S for organization, Kanban for visual control, Kaizen for improvement, and SMED to reduce setup times

- Integrate real-time technology with ERP and WMS systems to provide end-to-end visibility and enable quick decision-making during disruptions

- Empower cross-trained employees with lean thinking to create operational flexibility and accountability across all supply chain functions

Understanding Lean and JIT Principles

Lean manufacturing and JIT methodologies represent powerful approaches that have transformed supply chain management since their development in Japan. Let’s examine these principles in depth to understand how they can strengthen your operations against disruptions.

What is Just-in-Time (JIT)?

JIT is much more than an inventory technique; it’s a comprehensive management philosophy that synchronizes raw material orders with production schedules.

Originally developed by Toyota in the 1970s, JIT aims to receive goods precisely when needed in production, rather than storing excess inventory.

The fundamental principle of JIT is surprisingly straightforward: produce the right part, in the right place, at exactly the right time. This approach stands in stark contrast to traditional manufacturing methods that maintain large inventories of raw materials, work-in-process, and finished goods.

JIT operates through several key mechanisms:

- Pull-based production: Items move through manufacturing based on actual customer demand rather than forecasts

- Kanban signals: Visual cues that authorize and control inventory movement

- Takt time: The maximum allowable time to produce one unit based on the customer demand rate

Additionally, JIT helps prevent manufacturing failures by ensuring materials arrive exactly when needed, consequently reducing stockouts and production delays.

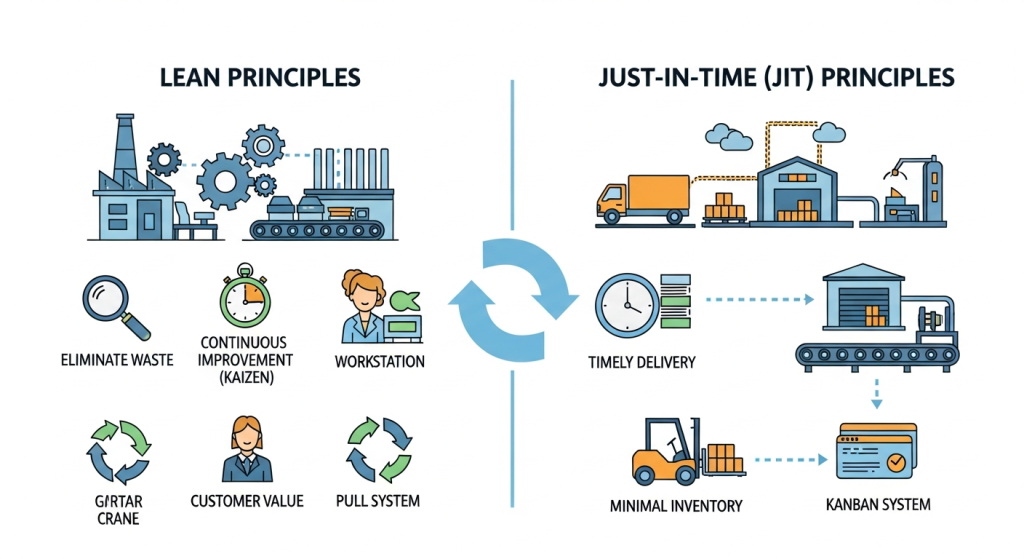

How Lean Manufacturing Complements JIT

Lean manufacturing expands upon JIT principles, focusing on eliminating all forms of waste across production processes. In essence, lean management practices seek to reduce waste and increase efficiency throughout the entire supply chain.

The core of lean thinking revolves around five principles:

- Defining value from the customer’s perspective

- Mapping the value stream to identify all steps

- Creating continuous flow through the production process

- Using pull systems to avoid overproduction

- Pursuing perfection through continuous improvement

Lean identifies seven distinct types of waste: overproduction, waiting time, transportation, processing, inventory, motion, and product defects. By systematically addressing these inefficiencies, companies can optimize operations and become more responsive to changing market demands.

Lean and JIT: Key Differences and Synergies

Although often used interchangeably, lean and JIT differ in several important ways. The primary distinction lies in their focus; JIT is business-centric, primarily concerned with inventory management and timing, whereas lean is customer-centric, addressing value creation across all operations.

In terms of scope, JIT has a narrower focus on synchronizing supply chains with production demands, while lean takes a more comprehensive approach by improving entire workflows. This difference extends to implementation as well; JIT requires precise coordination with suppliers, whereas lean emphasizes employee engagement and a continuous improvement culture.

Despite these differences, both methodologies create powerful synergies when combined. JIT serves as a practical implementation tool within the broader lean philosophy. For instance, the kanban system used in JIT becomes more effective when implemented alongside lean’s waste elimination practices.

Both approaches also share the goal of achieving high-volume production with minimal inventory. Toyota demonstrated this synergy by reducing lead times by one-third and production costs by 50% through integrated lean and JIT implementation.

Notably, lean and JIT strategies can still effectively help companies manage supplier diversity and develop contingency plans—contrary to criticisms following pandemic-related disruptions. The ultimate goal is not simply minimalism but rather maximizing control through the comprehensive visibility these systems provide.

Mapping and Streamlining Your Supply Chain

After understanding the fundamentals of lean and JIT, the next step is implementing these principles by thoroughly mapping your supply chain. To effectively apply lean manufacturing and JIT inventory management, you must first gain a clear picture of your entire operation.

Using Value Stream Mapping (VSM)

Value Stream Mapping is a powerful lean tool that creates a visual representation of all processes, information flows, and materials required to deliver a product or service. Originally developed by Toyota as part of their Production System, VSM provides a “door-to-door” view of your entire operation. This visualization helps identify opportunities for improvement that remain hidden in traditional supply chain views.

The primary objectives of VSM include:

- Documenting every step in the production process according to metrics like cycle times and wait times

- Identifying non-value-added activities throughout the flow

- Creating clear communication and collaboration between teams

- Visualizing delays, excess inventory, and production constraints

According to studies, 80-90% of tasks in typical business processes are wasteful because they don’t add value for customers. Through VSM implementation, companies like Gore have reported financial benefits approaching $5 million annually from supply chain improvements.

Identifying Waste and Bottlenecks

A bottleneck represents a point of congestion in your production system that severely slows or stops operations, ultimately creating delays and higher production costs. These inefficiencies might stem from short-term constraints like employee absences or longer-term causes such as supplier shortages.

To identify bottlenecks effectively:

First, collect high-value information by “walking the flow” and interviewing people who perform the tasks. This provides two critical benefits: your team sees the entire process firsthand, plus the actual operators can clarify misconceptions about how tasks are performed.

Subsequently, analyze cycle times or processing times. If any exceed your takt time, you’ve found a potential bottleneck causing waste such as overproduction, work-in-process inventory, or excess overtime.

Moreover, examine inventory levels at each stage, including raw materials, work-in-process, buffer stock, and finished goods. This analysis often reveals opportunities to reduce inventory through supermarket replenishment systems or first-in-first-out lanes between processes.

Aligning Production with Demand

The foundation of successful lean and JIT systems rests on pull-based production—triggering manufacturing activities only when actual customer demand materializes. This fundamental shift from traditional push systems prevents overproduction while eliminating waste associated with producing goods before they’re needed.

Takt time calculation serves as the cornerstone for aligning production pace with customer demand rate. By dividing available production time by customer demand, you ensure manufacturing processes produce products at precisely the rate customers require them. This synchronization prevents both overproduction and shortages while maintaining continuous flow.

The kanban system functions as the primary coordination mechanism for pull production, using visual signals to communicate demand throughout the supply chain. These signals indicate when materials should move between workstations or when production should begin for specific products, ensuring each production step responds only to actual downstream consumption.

Ultimately, streamlining your supply chain through these techniques creates numerous benefits: reduced lead times, optimized inventory levels, improved cash flow, enhanced quality control, and increased revenue. Companies that successfully implement these approaches gain not just tactical improvements but strategic advantages—seeing beyond immediate order fulfillment to anticipate future customer needs.

Building a Resilient JIT Supply Chain

The 2020 pandemic exposed major vulnerabilities in global supply chains, especially those relying exclusively on JIT systems. In fact, by the end of 2023, approximately 97% of companies worldwide were reconfiguring their supply chains to reduce exposure to disruptions. Let’s explore how to build resilience into your JIT supply chain without sacrificing its core benefits.

Diversifying Suppliers Strategically

Multi-source modeling creates a system of backup suppliers that prevents single points of failure. When sourcing suppliers, look for those that produce from multiple locations. This helps avoid complete disruption during environmental events. Both small businesses and large enterprises benefit significantly from supplier diversification; otherwise, critical operations like new employee onboarding or system implementations can be delayed due to equipment shortages.

Consider these strategic approaches:

- Implement a “supplier +1” strategy (used by 57% of industrial companies operating in China)

- Explore nearshoring or reshoring options for critical components

- Evaluate supplier performance using value stream mapping to identify top performers

Apple exemplifies successful supplier diversification by maintaining relationships with multiple suppliers for critical components like semiconductors and displays. This strategy allowed Apple to shift production when disruption risks increased during US-China trade tensions.

Creating Inventory Buffers Without Overstocking

After decades of emphasizing lean efficiency, many companies now acknowledge that some buffers are essential. The challenge is finding the “Goldilocks” inventory level that balances the extremes. JIT was never meant to be reckless inventory minimization, but rather holistic flow optimization.

For effective buffer management:

- Implement hybrid inventory models—apply JIT for stable, predictable demand items and keep extra safety stock for high-risk or variable-demand items

- Use dynamic buffer management that adjusts safety stock levels based on real-time data about demand and supply variability

- Conduct scenario planning (e.g., “What if demand surges 20% above forecast?”)

Procter & Gamble successfully combines safety inventory with data-driven monitoring tools. By strategically maintaining higher inventory levels in geographically diverse locations, P&G sustained operations during the pandemic when demand for essential products surged.

Developing Contingency Plans for Disruptions

A comprehensive supply chain contingency plan helps future-proof your organization. Start by evaluating your risk exposure, including economic, political, and geographic factors affecting your suppliers.

Use big data, predictive analytics, and modeling to simulate high-risk events and their potential impact. These simulations allow you to develop fallback options and communication workflows before disaster strikes. Performing tabletop exercises (TTX) for likely scenarios prepares your team for situations requiring extensive coordination and immediate action.

Explore Commport B2B network solutions for supply chain. Offering a wide range of solutions that includes EDI, VAN, GDSN and supply chain analytics solutions to enhance your contingency planning capabilities.

End-to-end visibility across all supply tiers is essential for effective response. In today’s digitized supply chains, implement automated alerts for deviations such as late deliveries or inventory dropping below thresholds. This visibility allows you to spot potential issues and respond swiftly, even in stressful circumstances.

Implementing Lean Tools for Risk Management

Implementing effective lean tools is essential for managing supply chain risks without compromising efficiency. These practical techniques help create robust systems that withstand disruptions while maintaining JIT principles.

1. 5S for Workplace Organization

5S principles provide a structured approach to workplace organization that directly impacts risk management. By implementing Sort, Straighten, Shine, Standardize, and Sustain, companies can identify potential safety hazards and improve operational efficiency. This systematic approach helps businesses establish clear distinctions between value-added versus non-value-added activities, creating predictability that mitigates risk.

Initially, the 5S method “cleans up” and organizes the workplace, typically serving as the first lean method organizations implement. Through this process, companies often reclaim valuable floor space and eliminate broken tools, scrap, and excess raw materials.

2. Kanban for Visual Inventory Control

Kanban systems use visual cues to signal when materials need replenishment, helping companies improve inventory accuracy and reduce stockout risks. This visual management technique specifically assists in developing contingency plans to ensure reliable material supply.

In practice, kanban inventory control involves physical elements like shelves, storage bins, cards, and boards that help employees easily notice when it’s time to reorder items. The kanban board visualizes different stages of the ordering process, allowing teams to track inventory items from ordering through receipt.

3. Kaizen for Continuous Improvement

Following pandemic disruptions, companies can apply lessons learned through Kaizen—a philosophy of continuous improvement where everything can and must be improved. This approach engages employees in eliminating overburdening of people and equipment, unevenness, and waste.

Kaizen combines collective talents within a company to create a powerful engine for improvement, typically following the PDCA cycle: Plan, Do, Check, and Act. This scientific approach to improvements helps teams develop contingency plans that respond effectively to changing circumstances.

4. Using SMED to Reduce Setup Time

SMED (Single-Minute Exchange of Die) dramatically reduces equipment changeover times—often to less than 10 minutes. The essence of this system involves converting changeover steps to “external” (performed while equipment runs) and streamlining remaining steps.

Practically, SMED implementation delivers several benefits for risk management: lower manufacturing costs through reduced equipment downtime, smaller lot sizes enabling more flexible scheduling, improved responsiveness to customer demand, lower inventory levels, and smoother startups. These advantages create resilience by allowing manufacturers to quickly adapt production when disruptions occur.

Training, Technology, and Team Involvement

The success of lean and JIT systems ultimately depends on people and technology working in harmony. Indeed, companies that excel at JIT maximize profits through effective inventory management and comprehensive data utilization.

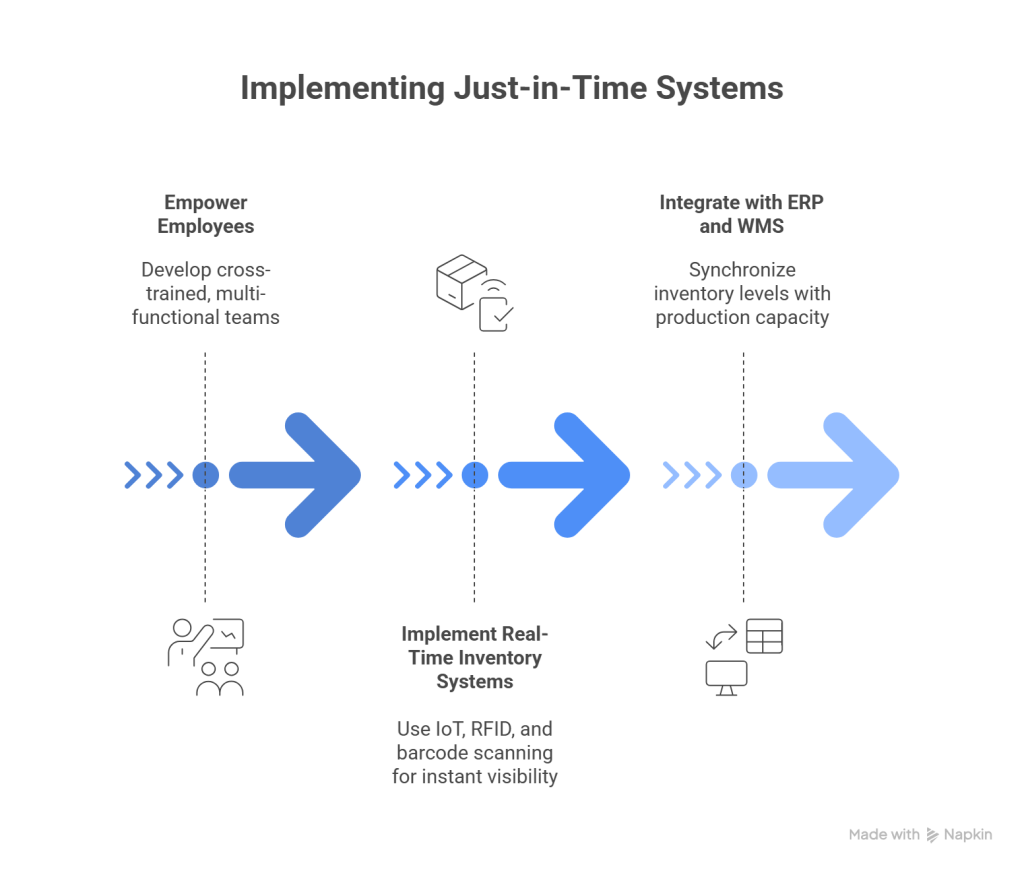

Empowering Employees with Lean Thinking

Successful JIT implementation requires total support from every operational division, particularly employees. By developing cross-trained, multi-functional team members, organizations create flexibility where staff can fill various positions as needed. This approach fosters accountability and autonomy, allowing workers to implement improvements without extensive management oversight. Companies like Kodiak Building Partners have delivered over $5 million in cost savings by empowering employees through lean principles.

Leveraging Real-Time Inventory Systems

Real-time inventory tracking systems utilize advanced technologies like IoT, RFID, and barcode scanning to provide instant visibility into inventory movements. Unlike traditional methods relying on manual data entry, these systems capture information automatically, enabling informed decisions without delay. Just-in-time training complements these technologies by providing employees access to task-specific information exactly when needed.

Integrating JIT with ERP and WMS Tools

Explore Commport B2B network solutions for supply chain. Offering a wide range of solutions that include EDI, VAN, GDSN, and supply chain analytics solutions.

Enterprise Resource Planning (ERP) systems gather critical data on shipping, customer satisfaction, loss prevention, and stock turnover—creating the information backbone necessary for JIT success. Integrating these systems with production schedules enables manufacturers to synchronize inventory levels with production capacity. This seamless coordination between technology platforms creates the end-to-end visibility essential for effective JIT implementation.

Conclusion

Mastering lean manufacturing and JIT principles offers a powerful framework for supply chain risk management that balances efficiency with resilience. Throughout this guide, we’ve explored how these methodologies work together to eliminate waste while maintaining operational flexibility. Companies that successfully implement these approaches gain not just cost savings but also strategic advantages against disruptions.

Undoubtedly, the traditional view of JIT as merely inventory minimization misses its true purpose—optimizing flow and creating visibility across the entire supply chain. Effective implementation requires strategic supplier diversification, thoughtful buffer planning, and robust contingency preparations. Additionally, lean tools like 5S, Kanban, Kaizen, and SMED provide practical mechanisms to identify risks before they escalate into crises.

Still, technology and people remain the foundation of any successful lean and JIT system. Real-time inventory tracking, ERP integration, and employee empowerment create the necessary infrastructure for quick, informed decisions during disruptions.

Therefore, the future of supply chain management lies not in abandoning lean and JIT principles but rather adapting them to today’s volatile environment. Companies must balance the efficiency goals of traditional JIT with strategic resilience planning. After all, modern supply chain excellence comes from finding the right balance—minimizing waste while maintaining sufficient flexibility to weather unexpected storms.

Most importantly, remember that lean and JIT implementation is a journey rather than a destination. Continuous improvement, regular assessment of risks, and adaptation to changing conditions will ensure your supply chain remains both efficient and resilient for years to come.

Commport B2B Network Solutions for Supply Chain

Top 30 KPIs you should track to improve your supply chain efficiency.

Commport business analytics solutions can help you track these metrics continuously with real-time data insights and dashboards.

Download NowFrequently Asked Questions

Just-in-Time (JIT) is a management philosophy that aims to receive goods exactly when needed in production, rather than storing excess inventory. It focuses on producing the right part, in the right place, at precisely the right time, helping to reduce waste and increase efficiency throughout the supply chain.

Lean manufacturing and JIT complement each other by focusing on eliminating waste and optimizing processes. While JIT primarily deals with inventory management and timing, lean takes a broader approach to improve entire workflows. Together, they create synergies that can significantly reduce lead times and production costs.

Building a resilient JIT supply chain involves strategically diversifying suppliers, creating smart inventory buffers without overstocking, and developing comprehensive contingency plans. It also requires implementing real-time inventory tracking systems and fostering a culture of continuous improvement.

Value Stream Mapping (VSM) creates a visual representation of all processes and information flows in a supply chain. It helps identify non-value-added activities, bottlenecks, and opportunities for improvement. By implementing VSM, companies can streamline operations, reduce lead times, and optimize inventory levels.

Employee empowerment is crucial for successful lean and JIT implementation. By developing cross-trained, multi-functional team members, organizations create flexibility and foster accountability. This approach allows workers to implement improvements without extensive management oversight, leading to increased efficiency and better problem-solving capabilities.