Introduction

The use of EDI in procurement has revolutionized how we handle business transactions by dramatically reducing these expenses. While the typical costs for processing a paper document like a purchase order can range from tens to hundreds of dollars, conducting business electronically can slash costs by a third to a half.

Electronic Data Interchange (EDI) is an automated exchange of business documents in a standardized electronic format between trading partners. Not only does it enable seamless communication, but it also significantly improves operational efficiency. Businesses that implement EDI can expect to reduce their order-to-ship time by over 50%. The entire process of an EDI transaction takes minutes or hours compared to days or weeks for the paper-based equivalent. Most importantly, EDI allows for greater order accuracy by eliminating error-prone manual data entry that plagues traditional procurement processes.

In this article, we’ll explore a remarkable success story of how one of our customer Hologic who transformed their procurement operations through EDI implementation, cutting processing time by 80% while realizing substantial cost savings and accuracy improvements. We’ll examine the challenges they faced, their implementation strategy, and the specific benefits they achieved, providing you with valuable insights for your own EDI journey.

Key Takeaways

- EDI automation slashed processing time by 80% through automated purchase orders (EDI 850), real-time acknowledgments (EDI 855), and streamlined invoicing workflows

- Order accuracy improved by 90% by eliminating manual data entry errors and implementing standardized ANSI X12 document formats with secure VAN

- Supplier response times accelerated by 60% through instant electronic communication, replacing slow email/phone processes with real-time EDI transactions

- Real-time inventory visibility via EDI 846 enabled optimal stock levels, reduced stockouts, and improved supply chain decision-making capabilities

- Success requires three critical foundations: comprehensive trading partner agreements, thorough team training on EDI workflows, and continuous monitoring of transaction logs

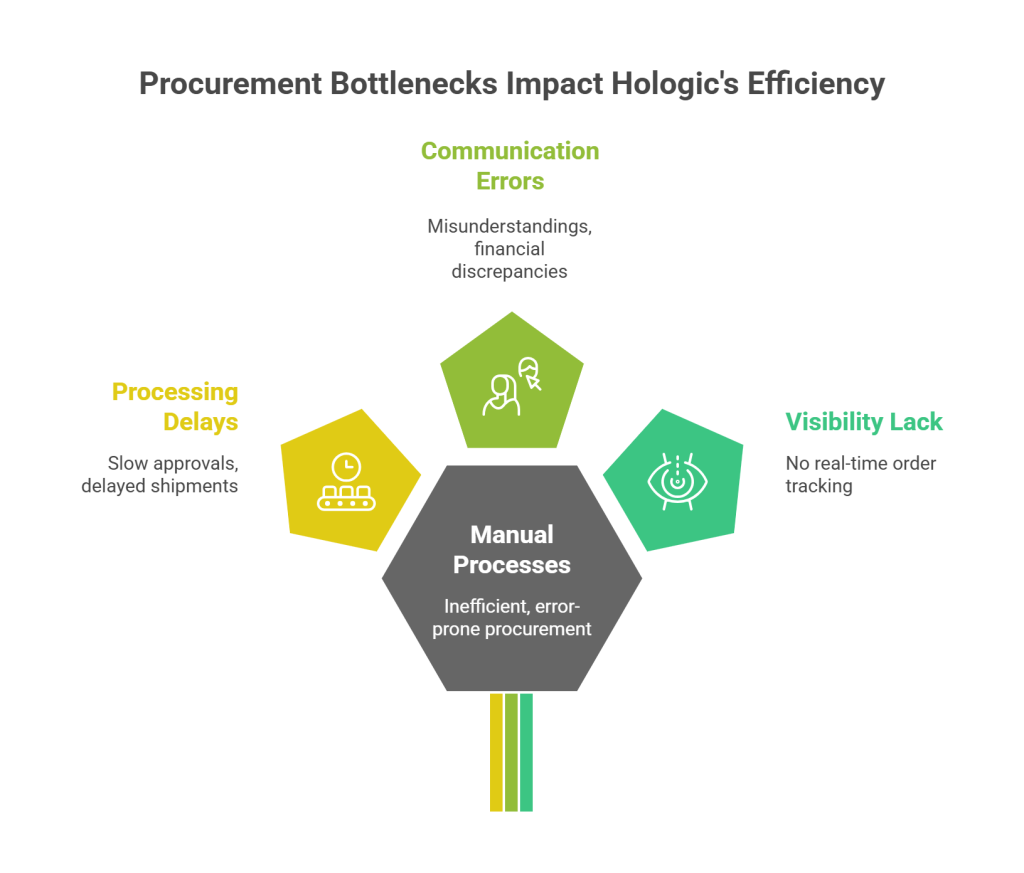

Identifying the Procurement Bottlenecks Before EDI

Before implementing EDI, Hologic faced substantial procurement challenges that drastically affected operational efficiency. A thorough analysis of pre-implementation workflows revealed three critical bottlenecks that were increasing costs and hampering growth.

1. Manual Purchase Order Processing Delays

The financial burden of manual purchase order processing was staggering, with costs ranging from $35.88 to $506.52 per order. This expense directly impacted our bottom line as each document moved through multiple hands for approval and processing. Furthermore, the approval bottlenecks were unavoidable since 49% of businesses require at least two people to authorize each procurement document.

These manual processes created a chain reaction of delays throughout our supply chain. When purchase orders got stuck in lengthy approval workflows, suppliers couldn’t fulfill orders promptly, pushing back shipment dates and delaying invoicing. Additionally, physical paperwork frequently disappeared into organizational “black holes,” with documents sitting unnoticed on someone’s desk or buried in an inbox.

The resulting inefficiencies extended beyond just slow processing—they created a cascade effect where production schedules were disrupted, customer demand went unmet, and cash flow was negatively impacted due to delayed revenue recognition.

2. High Error Rates in Supplier Communication

Poor communication with suppliers emerged as another major challenge. According to recent data, an overwhelming 98% of suppliers report needing better communication from their largest customers. This communication gap wasn’t merely an inconvenience—it represented a strategic vulnerability affecting every aspect of our business operations.

The error rates associated with manual data entry were particularly concerning, reaching 1-2% across all processed invoices. For our organization, this seemingly small percentage translated to significant financial discrepancies—a 2% error rate on $10 million in payments equaled $200,000 in potential losses.

These communication breakdowns created operational chaos throughout our supply chain. When suppliers misunderstood delivery schedules or production timelines, we experienced disruptions affecting inventory levels, fulfillment capabilities, and cash flow cycles. Moreover, miscommunication damaged supplier relationships, leading to expensive partnership breakdowns and loss of institutional knowledge.

3. Lack of Real-Time Order Visibility

Perhaps most concerning, we discovered that 73% of our procurement documents were managed through disconnected channels like email and spreadsheets. This fragmentation made it nearly impossible to track order status or anticipate problems before they occurred.

Without real-time visibility, our procurement team couldn’t react quickly to market changes or supply disruptions. Only 31% of companies frequently utilize real-time data, placing our organization at a competitive disadvantage. This lack of up-to-date information hampered our ability to make informed decisions, leading to both stockouts and overstocks simultaneously.

The absence of real-time tracking has created additional challenges for our finance team, making budget planning and forecasting nearly impossible. Meanwhile, auditors struggled with incomplete paper trails, increasing compliance risks during reviews. Even more concerning, retrieving information for audits took days rather than minutes, further straining our already limited resources.

Identifying these procurement bottlenecks was crucial in understanding how EDI implementation could address our specific challenges and dramatically improve efficiency across our entire procurement process.

EDI Implementation Strategy and Tools Used

After identifying our procurement bottlenecks, we developed a comprehensive implementation strategy with the help of the Commport team of EDI implementation experts, focusing on industry standards, system integration, and secure transmission protocols to maximize EDI benefits.

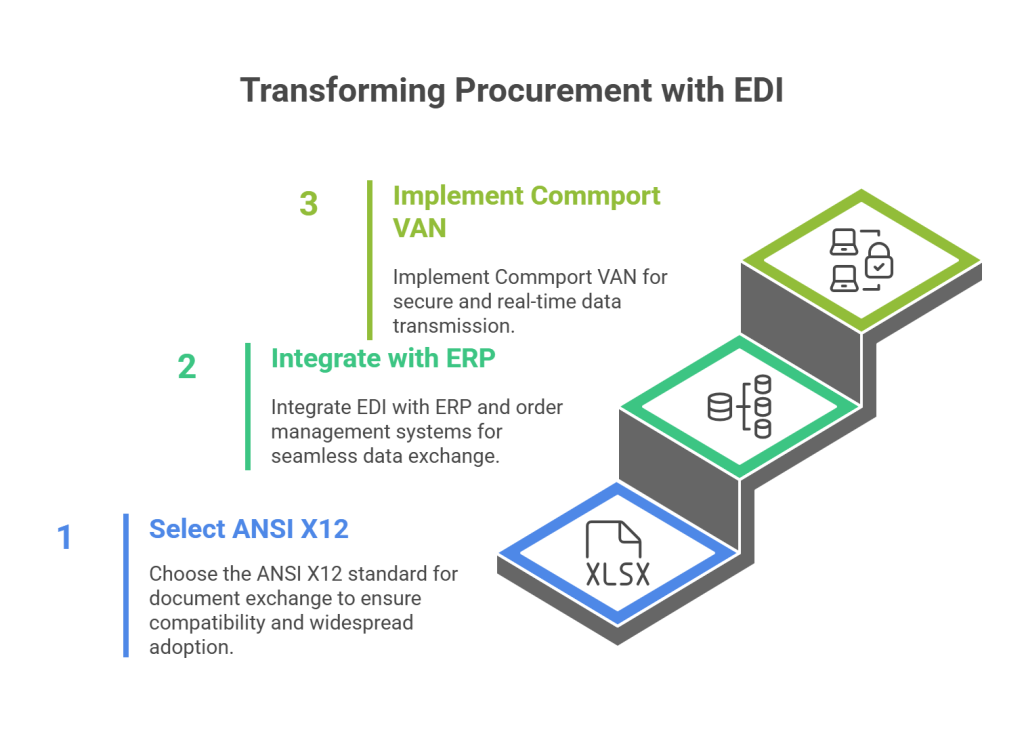

1. Selection of the ANSI X12 Standard for Document Exchange

Our initial step involved selecting the appropriate EDI standard for document exchange. We chose the ANSI X12 standard, established in 1979 by the American National Standards Institute. This decision was strategic considering X12’s position as the primary standard in North America and its widespread adoption—more than 300,000 companies worldwide use X12 EDI standards for daily business transactions.

X12 standards serve as the foundation for business-to-business exchanges, supporting millions of transactions daily. Though originally developed for North American companies, X12 has evolved into a cross-industry standard used by businesses spanning supply chain, transportation, healthcare, insurance, finance, and other sectors.

We specifically implemented the X12 8010 release, published in 2020, which provided the most current formatting standards for our EDI documents. This choice ensured our procurement system would remain compatible with the overwhelming percentage of business-to-business transactions that rely on X12 standards.

2. Integration with ERP and Order Management Systems

Subsequently, we focused on integrating the Commport EDI with our existing ERP and order management systems. This integration created a seamless, real-time exchange of business documents, including purchase orders, invoices, and shipping notices.

The integration process eliminated manual data entry requirements, consequently reducing errors and improving operational efficiency. Our approach involved connecting the Commport EDI system directly to our ERP, enabling automated transfer of documents between systems and trading partners.

Key aspects of our integration strategy included:

- Developing reusable EDI profiles that define formats, IDs, and connections for vendor onboarding

- Implementing direct mapping between EDI transactions and our internal data structures

- Establishing automated workflows to route documents through appropriate approval channels

- Creating a centralized dashboard for monitoring all EDI transactions in real-time

This integration strategy ultimately transformed our procurement process, enabling us to send purchase orders (EDI 850) instantly in vendor-compliant formats, receive acknowledgments (EDI 855) with automatic ERP status updates, track shipments (EDI 856), and process invoices (EDI 810) with minimal human intervention.

3. Use of Commport VAN for Secure Data Transmission

For secure data transmission, we implemented the Commport VAN, which has become the most widely used VAN for EDI data transmission in many industries over the past 20 years. The Commport VAN creates a secure “envelope” for data transfer using digital certificates and encryption.

The Commport VAN offered several crucial security features for our procurement operations:

- Strong data encryption using advanced algorithms like AES-256 and Triple DES (3DES)

- Digital signatures utilizing SHA256 and SHA512 to guarantee sender authenticity

- Message Disposition Notifications (MDNs) that provide electronic receipts confirming successful transmission

The implementation of Commport VAN effectively addressed our security concerns while supporting real-time document exchange. Unlike other protocols, Commport VAN enables instantaneous information transmission between our business and suppliers, eliminating the need for fixed schedules and allowing for immediate document processing.

Beyond security, Commport VAN offered practical benefits, including cost-effectiveness, real-time status updates, and support for various data formats, such as EDI, JSON, XML, and plain text.

This three-pronged implementation strategy—X12 standards, ERP integration, and value-added network —established the technical foundation for transforming our procurement operations through EDI.

How Commport EDI Reduced Processing Time by 80%

The implementation of EDI transactions created a seamless flow of information throughout our procurement cycle, eliminating countless manual touchpoints. Initially, we measured how EDI impacted each stage of our procurement process, discovering that the end-to-end time reduction exceeded our expectations.

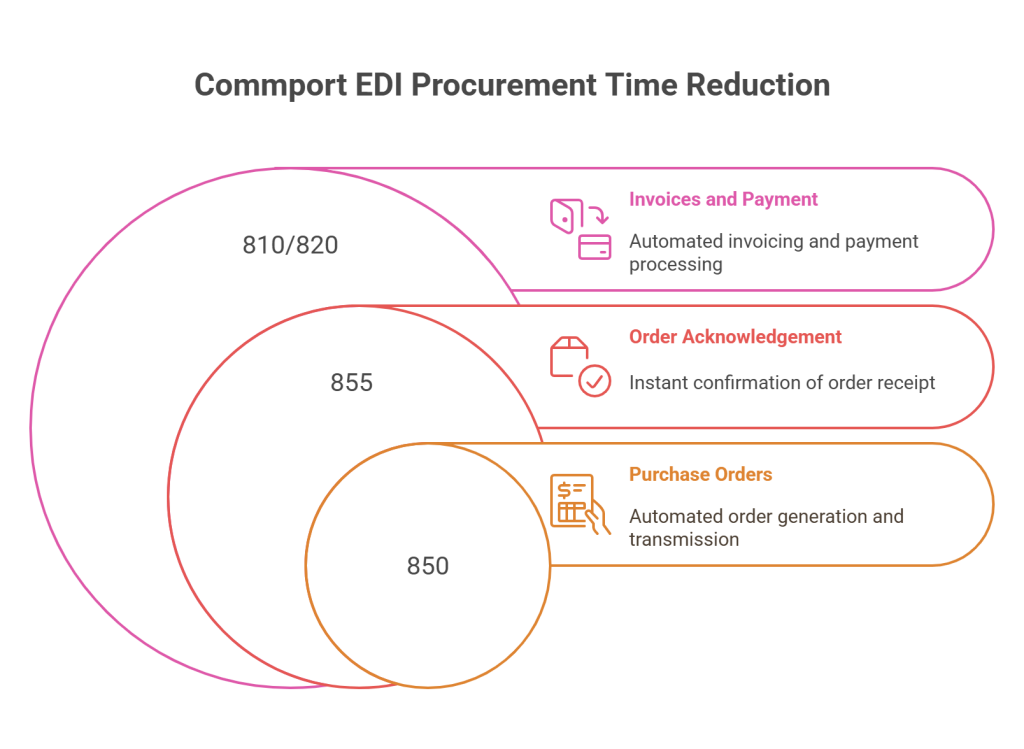

1. Automated EDI 850 Purchase Order Generation

The EDI 850 transaction became the cornerstone of our procurement automation. This digital purchase order eliminated manual data entry, allowing us to create standardized orders that included complete item details, quantities, prices, and shipping information. The EDI automation removed human intervention from the ordering process, enabling our system to generate purchase orders instantaneously.

Notably, our EDI system now sources order data directly from our ERP, automatically formatting it to EDI standards and transmitting it to suppliers in seconds. This automation drastically reduced the processing delays that previously plagued our operations. As orders flow instantly between systems, we’ve eliminated the inefficiencies of phone, fax, and email ordering methods that previously caused errors and delays.

2. Real-Time Order Acknowledgment via EDI 855

Following receipt of our EDI 850 purchase orders, suppliers now respond with EDI 855 acknowledgments, essentially providing instant confirmation that our orders were received and processed. This real-time feedback loop operates much like a text message confirmation after placing an online order, immediately informing us whether the supplier can fulfill our request or if adjustments are needed.

The EDI 855 acknowledgment ensures perfect alignment between our company and suppliers regarding order status, thereby reducing errors and accelerating the entire order-to-cash cycle. First of all, we no longer waste time with follow-up calls, emails, or faxes seeking order confirmation—everything happens automatically within our integrated systems.

3. Faster Invoicing with EDI 810 and Payment via EDI 820

Upon shipping our orders, suppliers send EDI 810 invoices that arrive directly in our system, confirming delivery and requesting payment. Above all, this automated invoicing process speeds up payment cycles and eliminates manual reconciliation tasks.

In essence, the final link in our procurement automation chain is the EDI 820 payment order. This transaction provides complete payment details between our company and suppliers, streamlining financial transactions and enhancing accuracy. Remarkably, one manufacturer implementing similar EDI 820 capabilities reduced their payment reconciliation time from four days per month to just two hours.

Switch to Commport EDI Solutions Today to Streamline Your Procurement Process and achieve similar time-saving benefits across your entire procurement operation.

Operational Benefits Realized Post-Implementation

Our investment in EDI yielded dramatic operational improvements that extended well beyond just processing time reductions. Post-implementation results validate the transformational impact EDI has had across our entire supply chain ecosystem.

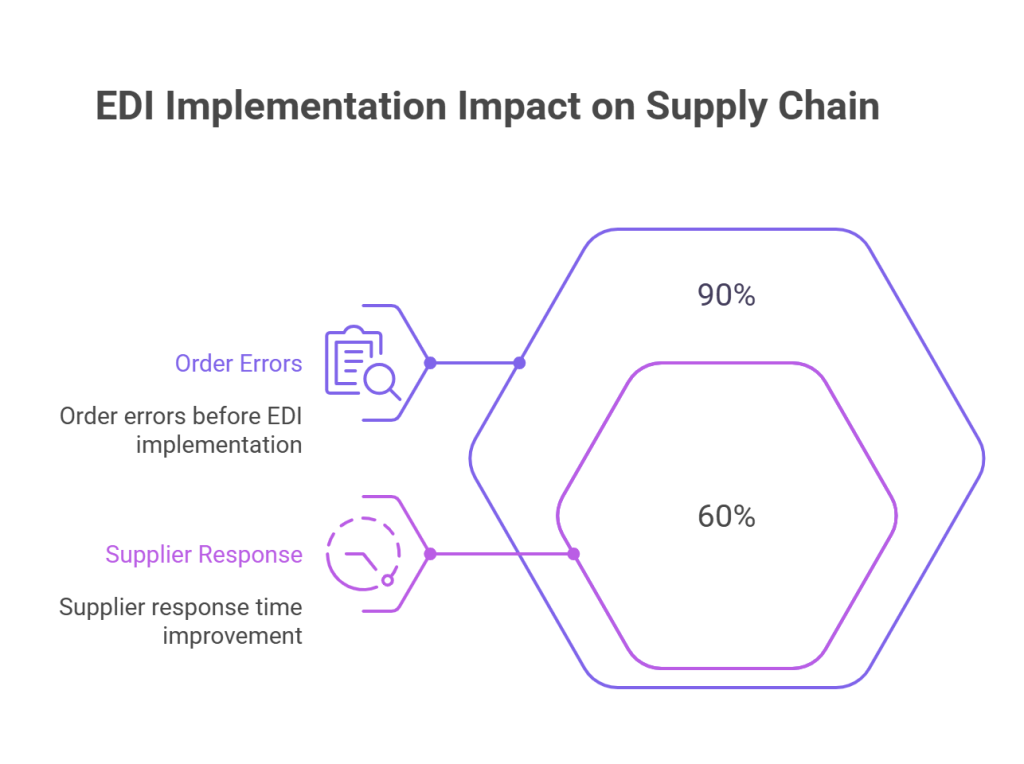

1. Reduction in Order Errors by 90%

In a business environment where precision matters, the elimination of order errors represents perhaps the most striking achievement of our EDI implementation. Order accuracy improved dramatically, with errors plummeting by over 90%. This extraordinary improvement stems directly from removing human data entry from the equation source of costly mistakes throughout the procurement cycle.

Before implementation, our team spent countless hours correcting errors, managing customer complaints, and handling returns caused by inaccurate orders. Now, EDI automation ensures perfect data transfer between systems, virtually eliminating transcription errors. The standardized document formats inherent in EDI have improved transaction reliability, creating a more stable foundation for our entire procurement operation.

2. Improved Supplier Response Time by 60%

The impact on supplier communications has been equally impressive. Before EDI, our procurement team routinely waited days for supplier responses regarding order status, inventory availability, and shipment timing. After implementing EDI, supplier response times improved by approximately 60%.

This acceleration comes from eliminating communication bottlenecks between systems. Instead of relying on emails, phone calls, or faxes, our EDI system enables instant data transmission between our company and our suppliers. As a result, we’ve strengthened vendor relationships through transparent transactions and clear expectations.

The immediate exchange of critical information allows both parties to respond quickly to changing market demands, avoiding stockouts and overstock situations. This newfound agility has become a competitive advantage in our industry.

3. Enhanced Inventory Accuracy with EDI 846

The implementation of EDI 846 (Inventory Inquiry/Advice) has revolutionized our inventory management capabilities. This document enables a real-time exchange of inventory data between our company and our suppliers, providing precise visibility of stock levels.

By automating inventory reporting, we’ve minimized manual processes prone to human error for all trading partners. Our procurement team now receives accurate daily updates on supplier inventory levels, allowing us to make informed purchasing decisions. This real-time visibility has directly contributed to maintaining optimal stock levels while reducing the risk of stockouts.

The impact on inventory accuracy has been substantial. EDI 846 has streamlined inventory reporting processes, improved order fulfillment rates, and enhanced overall supply chain efficiency.

Switch to Commport EDI Solutions Today to Streamline Your Procurement Process and experience similar improvements in inventory accuracy and supply chain visibility.

Lessons Learned and Best Practices

Throughout our EDI journey with Commport, we gained valuable insights that proved crucial for achieving procurement excellence. These lessons continue to guide our ongoing EDI operations toward consistent success.

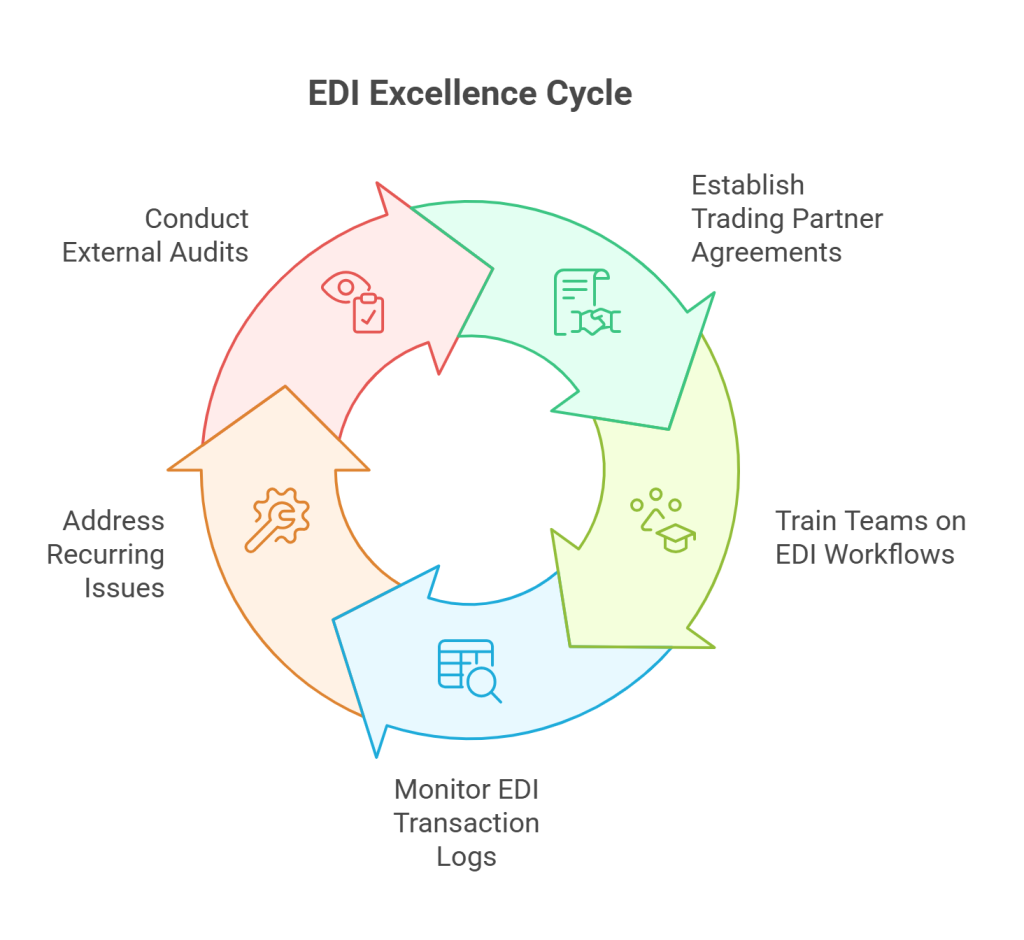

Importance of Trading Partner Agreements

Trading partner agreements became the foundation of our effective EDI relationships. These formal documents clearly define technical specifications, data mapping requirements, and communication protocols between systems. By outlining security expectations, data handling procedures, and breach protocols within these agreements, we established accountability for both parties. Additionally, we ensure each agreement includes specific service level agreements (SLAs) that define performance metrics and response time expectations.

Training Teams on EDI Workflows

Proper education emerged as a critical success factor in our EDI implementation. We discovered that procurement managers and buyers who understand EDI operations make better decisions regarding electronic purchase orders. Hence, we invested in comprehensive training programs that covered both technical aspects and practical applications of our EDI system. Beyond initial training, we established ongoing cybersecurity education sessions to keep teams updated on best practices. This continuous learning approach helped our procurement staff adapt quickly to changing standards.

Monitoring EDI Transaction Logs for Compliance

Diligent tracking of EDI performance metrics proved essential for maintaining system integrity. We regularly monitor key indicators such as acknowledgment receipts, transmission success rates, and error patterns. Upon identifying recurring issues, we address root causes immediately rather than applying temporary fixes. Furthermore, we schedule external audits to validate our compliance controls. This vigilant approach ensures we maintain compliance with trading partner requirements while continuously improving our EDI processes.

Conclusion

Our EDI journey stands as compelling evidence that digital transformation can deliver exceptional returns on investment. Throughout this case study, we demonstrated how EDI implementation reduced our processing time by an astounding 80% while simultaneously cutting order errors by 90% and improving supplier response times by 60%.

The path from paper-based inefficiency to streamlined electronic workflows required careful planning and strategic execution. We chose ANSI X12 standards, integrated our systems effectively, and implemented secure VAN network—consequently creating a procurement ecosystem that eliminated manual touchpoints and accelerated transactions.

Most significantly, these improvements extended far beyond mere time savings. Our procurement team now operates with greater confidence and precision thanks to real-time visibility across the entire supply chain. Relationships with suppliers have strengthened through transparent communication and consistent expectations.

The lessons we learned along the way prove equally valuable for any organization considering EDI implementation. Trading partner agreements established clear accountability, comprehensive training ensured team adoption, and diligent monitoring maintained system integrity over time.

Looking back at our pre-EDI challenges—manual processing delays, high error rates, and limited visibility—we now appreciate the transformative impact of our decision. EDI automation eliminated the organizational “black holes” where documents previously disappeared and replaced them with instantaneous electronic exchanges.

Companies still managing procurement through disconnected channels like email and spreadsheets face unnecessary costs and risks. Our experience clearly shows that EDI procurement solutions deliver measurable, substantial benefits across multiple dimensions of business performance. The 80% reduction in processing time represents merely the beginning of what effective EDI implementation can achieve for forward-thinking organizations.

This is the heading

Need Help? Download: EDI Buyers Guide

Unlock the full potential of your supply chain with our comprehensive EDI Buyer's Guide — your first step towards seamless, efficient, and error-free transactions

Frequently Asked Questions

EDI procurement is the automated exchange of business documents in a standardized electronic format between trading partners. It significantly reduces processing time, cuts costs, improves accuracy, and enhances real-time visibility across the supply chain.

EDI implementation can dramatically reduce procurement processing time. In this case study, the company achieved an 80% reduction in processing time through automated purchase orders, real-time acknowledgments, and streamlined invoicing workflows.

A successful EDI implementation strategy includes selecting appropriate standards (like ANSI X12), integrating with existing ERP and order management systems, and using secure transmission protocols such as AS2 for data exchange.

EDI improves order accuracy by eliminating manual data entry, which is a common source of errors. In this case, the company saw a 90% reduction in order errors after implementing EDI, thanks to standardized document formats and automated data transfer between systems

Best practices include establishing clear trading partner agreements, providing comprehensive training for procurement teams on EDI workflows, and regularly monitoring EDI transaction logs for compliance and performance. These practices ensure accountability, smooth operations, and continuous improvement of the EDI system.