Introduction

EDI reporting refers to generating detailed reports and dashboards from EDI transaction data. These reports can track important metrics like transaction volume, order fulfillment accuracy, inventory levels, on-time delivery, and more. By analyzing this information, businesses can optimize operations, reduce errors, and improve collaboration with suppliers.

For example, supply chain managers can set up reports to monitor how many orders are received on time and in full, or to detect when shipping notices do not match actual deliveries. With real-time visibility into such EDI data, companies can react quickly to issues—correcting stock errors or supplier delays before they cascade—thus keeping goods moving smoothly. In short, EDI reporting transforms the raw EDI file data into strategic intelligence across procurement, production, logistics, and finance.

Key Takeaways

- EDI standardization drives efficiency: Modern supply chains rely on EDI file standards (like X12, EDIFACT, UBL) to automate document exchange. This standardization ensures quick, accurate data flows.

- EDI Reporting automates operations: EDI reporting tools capture every transaction and generate custom reports on inventory, orders, and invoices. Real-time EDI dashboards let managers see exactly what is happening in their supply chain at any moment.

- Diverse formats for global trade: There are multiple EDI formats tailored to different regions and industries (e.g. ANSI X12 in North America, EDIFACT in Europe, TRADACOMS for UK retail, VDA for German automotive, UBL/PEPPOL for e-invoicing).

- Analytics and supplier scorecards: Beyond basic transaction reports, modern EDI reporting includes analytics and KPIs. Supplier scorecards track metrics like on-time delivery, fill rate, and invoice accuracy.

- EDI remains future-proof and growing: Despite new technologies, EDI continues to expand. The global EDI market is growing at double-digit rates, and most executives believe EDI will remain central to B2B integration.

Understanding EDI Reporting

Understanding EDI reporting starts with knowing EDI files and formats. An EDI file is a structured text file that follows industry-standard syntax. Each EDI document (e.g. a PO or invoice) is composed of segments and elements that convey specific data fields.

For example, in an ANSI X12 purchase order (transaction set 850), segments like ISA/IEA, GS/GE, ST/SE wrap the envelope of the transmission, while segments like N1 (name), IT1 (item details) contain the actual order data.

Different industries and regions use different EDI formats: UN/EDIFACT is the United Nations standard used globally (especially outside North America), while ANSI X12 is the predominant North American standard.

Each format defines how data is delimited and structured, but all serve the same purpose of enabling automated data exchange. In practice, many companies work with multiple EDI formats: for example, a supplier might send orders in EDIFACT to European retailers, invoices in X12 to U.S. distributors, and use UBL/PEPPOL for cross-border e-invoicing.

When trading partners use different EDI formats, translation or mapping tools convert data between these schemas. As one expert notes, “the fastest and most efficient way” to handle multiple formats is via a managed EDI provider who can receive a document in one format and output it in another over any protocol.

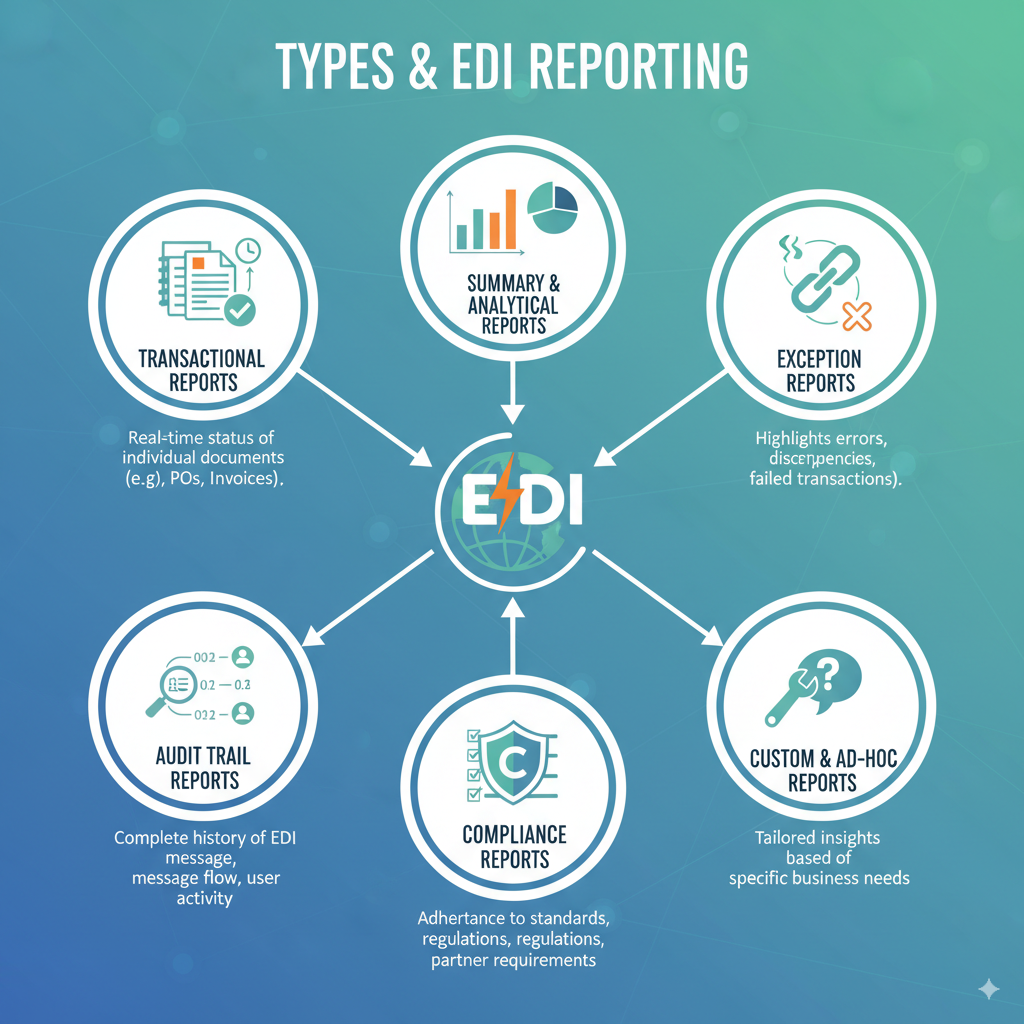

Types of EDI Reporting

EDI reporting can take many forms depending on business needs. At a high level, we can categorize reports by their purpose and audience:

1. Operational Transaction Reports

This type of report summarizes EDI data over a period (daily, weekly, or monthly) for internal teams. For example, a purchasing manager might receive a daily report of all PO transmissions and acknowledgments, highlighting any orders that were rejected or not acknowledged. A warehouse team might use reports of incoming shipping notices (ASN or dispatch advice documents) to prepare for expected arrivals. These reports typically include metrics like total orders sent/received, rejection/error counts, and throughput. EDI transaction logs also serve as audit trails, logging the date/time and status of each file. Real-time access to these logs can alert managers to urgent issues – for instance, if a critical invoice has not been received by 5 PM, or if an advanced shipping notice (EDI 856 or DESADV) is missing for an inbound truck.

2. Supplier Performance and Compliance Scorecards

Supply chain teams often use EDI data to monitor how well trading partners follow agreed processes. Analytics platforms provide supplier scorecards that track on-time delivery, data quality, and compliance rates. For example, one solution reports a supplier’s invoice accuracy and timeliness against contract expectations. Key performance indicators (KPIs) such as on-time fulfillment, in-full rate (complete shipments), and EDI document compliance are common. These scorecards help procurement and operations identify top-performing suppliers and address laggards. By giving vendors feedback on metrics like error rate or response time, companies drive improvements. For instance, Commport highlights that analytics reports can “report on your suppliers’ ability to submit correct invoices on time” and flag which suppliers meet or miss requirements. Such insights empower businesses to reduce errors before they impact downstream processes.

3. Financial and Regulatory Reports

Some EDI reports focus on financial reconciliation or compliance. For example, accounts payable teams can compare EDI invoices against purchase orders to automatically detect price variances or duplicate billing. Reports may summarize total spending by supplier or by category, accelerating month-end closing. In regulated industries, EDI reporting might also involve generating mandated filings: for instance, some governments require periodic electronic reports of trade or inventory levels. While not “EDI file formats” per se, these reports leverage the same data. They ensure that EDI data meet legal standards (e.g. e-invoicing mandates often require logging each invoice exchange). By centralizing compliance data, EDI reporting helps avoid fines and ensures audit readiness.

4. Business Analytics and Trend Reports

Beyond day-to-day operations, EDI data can feed higher-level analysis. Long-term trend reports—updated weekly or monthly—allow supply chain managers to spot patterns over time. For example, analyzing 6 months of EDI order data might reveal seasonal demand surges or chronic shipping delays from a specific port. Companies can correlate EDI transaction trends with external factors (like promotions or weather events) to make strategic decisions. Some organizations use machine learning on historical EDI data to forecast demand or optimize reorder points. In all cases, EDI Reporting tools can output charts and dashboards (often via integrated BI tools) that summarize key trends, facilitating decision-makers who need a big-picture view.

Each type of report may be delivered in different formats: as emailable PDFs, Excel spreadsheets, or interactive web dashboards. Many modern EDI systems allow users to customize reports by department or role. For instance, a logistics manager might prioritize shipment and ASN reports, while a finance director focuses on invoice and payment analytics. Reports can be scheduled (daily/weekly) or viewed ad hoc. Some EDI platforms even embed analytics directly in an ERP screen via API, so the data is available where managers already work

Key Features of Effective EDI Reporting

Across these varied report types, certain features are essential:

1. Real-Time Data Access

Modern EDI reporting systems provide live visibility into ongoing transactions. This means that as soon as a partner sends a file (such as an advance ship notice), the information is immediately available on the dashboards. Real-time reporting enables supply chain teams to identify and rectify issues promptly: for example, they can immediately detect if a shipment is delayed (since the expected ASN has not arrived) and reroute inventory as necessary. As one industry article notes, real-time EDI insights help businesses “react promptly to any discrepancies or issues” and prevent bottlenecks.

2. Customizable Reports

Reports should be tailored to each business’s needs. EDI tools typically allow users to define the content and frequency of reports – whether daily, weekly, or monthly – and format the output (tables, graphs, etc.). For example, a marketing department might schedule a weekly report on sales order trends, while manufacturing gets a daily exception report on order changes. The ability to customize ensures that each team sees the most relevant metrics. Tailored reports support smarter decisions: logistics might watch fulfillment rates, while finance tracks invoice compliance. This flexibility is crucial in complex supply chains, where one-size-fits-all reports are insufficient

3. Integration with Core Systems

Effective EDI reporting usually ties into other enterprise systems like ERP (Enterprise Resource Planning), WMS (Warehouse Management Systems), and CRM When EDI data flows into a unified system, reports automatically include all related information. For instance, an ERP might append cost and customer data to an EDI invoice report, giving a full financial picture. Integration also ensures consistency: an order number in an EDI report can directly link to the order record in the ERP. This “single source of truth” prevents data silos and manual reconciliation. In practice, many companies use middleware or cloud-based EDI hubs that consolidate EDI messages and push data to back-office systems, enabling comprehensive reporting.

4. High Data Accuracy

By automating the data exchange, EDI reduces human errors. Standard formats enforce consistent data (product codes, quantities, dates, etc.), and automated validation catches mistakes before processing. Accurate EDI data means reports reflect the true status of the supply chain. For example, if an order is missing a price or a part number, the EDI system flags it immediately so the issue can be corrected before it skews reports. Reliable reporting leads to confidence: inventory levels and sales figures reported from EDI feeds match the real world, avoiding costly overstock or out-of-stock decisions.

5. Analytics and Visualization

The best EDI reporting solutions go beyond static data dumps. They include analytics engines that highlight insights and trends. Dashboards can visualize key metrics (fill rate charts, error rate trends, etc.) and even trigger alerts. For example, a drop in on-time delivery percentage or a spike in invoice rejections can automatically notify managers. Graphical scorecards make it easy to spot performance gaps. Some platforms even use advanced analytics to benchmark supply chain operations against industry standards. As one provider emphasizes, analytics let you “optimize on-shelf availability, reduce inventory overhead and ultimately increase revenues”. In other words, EDI reporting is not just about raw data — it’s about turning that data into clearer insights and proactive actions.

Benefits of EDI Reporting

Leveraging EDI reporting yields substantial advantages for supply chain and operations teams:

1. Enhanced Operational Efficiency

Automating EDI dramatically speeds up processes. No more manual entry of orders or invoices — everything flows automatically between partner systems. This frees staff from tedious tasks so they can focus on strategic work. The result is faster order-to-cash and procure-to-pay cycles. In fact, studies show EDI can shorten transaction times by over 60% compared to manual methods. Reports update quickly without delays, so companies can move goods and funds faster. With integrated dashboards, managers can identify and eliminate workflow bottlenecks immediately, further streamlining operations.

2. Improved Data Accuracy and Integrity

EDI reporting ensures that the information decision-makers see is reliable. Standardized formats mean data is validated and consistently structured before it’s used. This minimizes mistakes like missing fields or wrong units, which were common in paper or ad-hoc electronic exchanges. Accurate data in reports means inventory records and order statuses are trustworthy, helping avoid problems like stockouts or overstock. As Commport notes, better data accuracy from EDI helps businesses “avoid costly mistakes such as overstocking or stockouts”. In short, knowing your data is correct allows managers to make confident decisions.

3. Cost Savings

Automating reports and data flows cuts costs across the board. Companies eliminate printing, postage, and manual labor associated with paper processes. With EDI reporting, staff spend less time fixing errors or hunting for information. Studies have shown that EDI can reduce operational expenses by roughly 35%. When you include indirect costs—like lost sales from errors or high labor costs from manual processing—a large retailer estimated EDI orders cost only about 10% as much as manual ones. Savings also come from inventory benefits: faster reporting and processing mean lower working capital tied in stock. Ultimately, the ROI of a robust EDI reporting system is high, with rapid payback from efficiency gains.

4. Better Decision-Making

With EDI reporting, data-driven management becomes possible. Real-time metrics and trend reports put the latest information in front of leadership. For example, retail managers can instantly see sales trends by day and adjust promotions or replenishment orders accordingly. A manufacturer can use EDI data to balance production schedules against incoming orders, preventing bottlenecks. Because reports can be customized, each department gets the insights it needs — from marketing (customer order patterns) to logistics (shipment reliability) to finance (spend analysis). As Commport explains, access to timely, accurate data through EDI reporting “allows managers to make informed decisions that can improve efficiency, reduce costs, and enhance customer satisfaction”. In an unpredictable market, this visibility can be a competitive advantage.

5. Strengthened Supplier Relationships

When both sides share clear data, collaboration improves. EDI reporting often includes shared portals or scorecards for suppliers, so they see the same performance metrics as their customers. For example, suppliers can log into an analytics portal to view on-time rates and compliance reports, understanding exactly where they stand. This transparency builds trust and speeds up resolution of issues. Companies also gain agility: if a supplier is underperforming, reporting highlights the problem early. Conversely, high-performing suppliers are identified and can be given more business. Overall, EDI reporting promotes accountability and opens communication, making the supply chain more resilient.

Conclusion

EDI reporting is an essential capability for modern supply chain management. By leveraging standardized EDI files and formats along with powerful reporting tools, businesses gain transparency and control. Real-time dashboards, customizable scorecards, and automated analytics turn every EDI data into an opportunity for improvement. As global commerce becomes ever more connected and data-driven, the diverse types of EDI reporting outlined here will help companies make smarter decisions, cut costs, and strengthen supplier collaboration. The future of supply chain excellence is rooted in the real-time insights that EDI reporting provides.

Commport EDI Solutions - Trusted by 6000+ Brands

Need Help? Download: Commport's EDI Buyers Guide

Unlock the full potential of your supply chain with our comprehensive EDI Buyer's Guide — your first step towards seamless, efficient, and error-free transactions

Frequently Asked Questions

EDI reporting involves the electronic exchange of standardized business documents between trading partners. It’s important because it automates and streamlines communication, reducing errors, improving efficiency, and providing real-time visibility across the supply chain.

Common EDI transaction types include EDI 850 (Purchase Order), EDI 810 (Invoice), EDI 856 (Advance Shipping Notice), EDI 997 (Functional Acknowledgment), and EDI 820 (Payment Order/Remittance Advice). Each serves a specific purpose in the business transaction lifecycle.

EDI 850 is an electronic version of a purchase order that follows a standardized format. Unlike traditional POs, it can be automatically generated, transmitted, and processed by computer systems, reducing manual data entry and accelerating the procurement cycle.

EDI 856 provides detailed information about upcoming deliveries, allowing recipients to prepare for incoming shipments. This improves receiving efficiency, enhances inventory management, and provides better tracking capabilities throughout the shipping process.

Implementing EDI reporting typically results in reduced operational costs, minimized errors, enhanced supply chain visibility, and improved trading partner relationships. It automates many manual processes, freeing up staff time and enabling businesses to operate more efficiently and competitively in the digital marketplace.