Introduction

For food and beverage companies, utilizing GDSN data pools has become essential for maintaining accurate product information across their supply chains.

With nearly 5,000 foodservice companies currently exchanging data through this network, GDSN connects over 30 certified data pools and 35,000 companies worldwide.

Essentially, global data synchronization enables standardized article master data to flow seamlessly between trading partners. This system is particularly valuable for food brands, ensuring their products appear correctly on retailer websites and distributor catalogs.

Additionally, GDSN helps companies optimize inventory levels, reduce waste, ensure product freshness, and comply with food safety regulations. The targeted use of specification data can significantly cut costs while promoting sustainable production and distribution processes throughout the food industry.

Understanding GDSN in the Food and Beverage Supply Chain

The Global Data Synchronization Network (GDSN) serves as the backbone for product data exchange across the food and beverage supply chain. This standardized system enables companies to share crucial product information efficiently, creating a foundation for seamless operations from production to retail.

What Does GDSN Stand For and How It Works

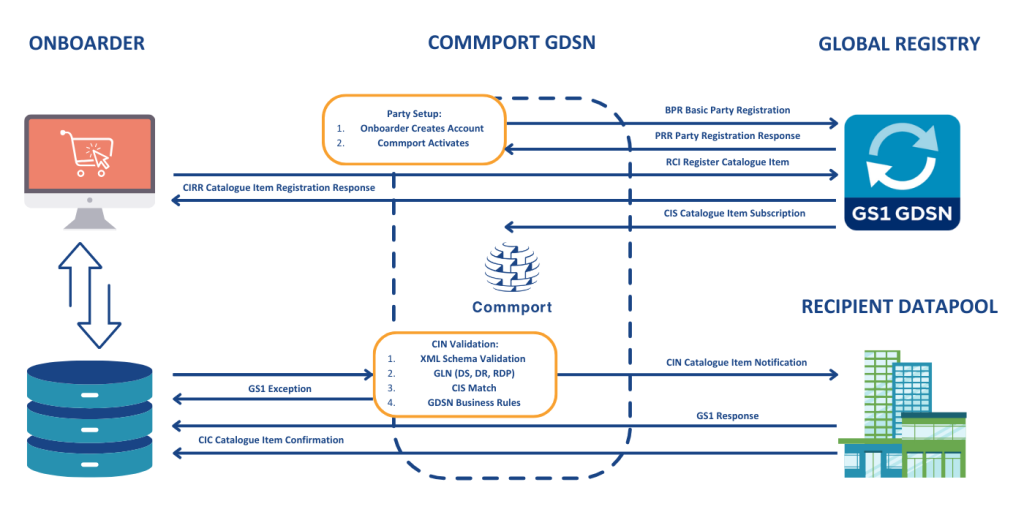

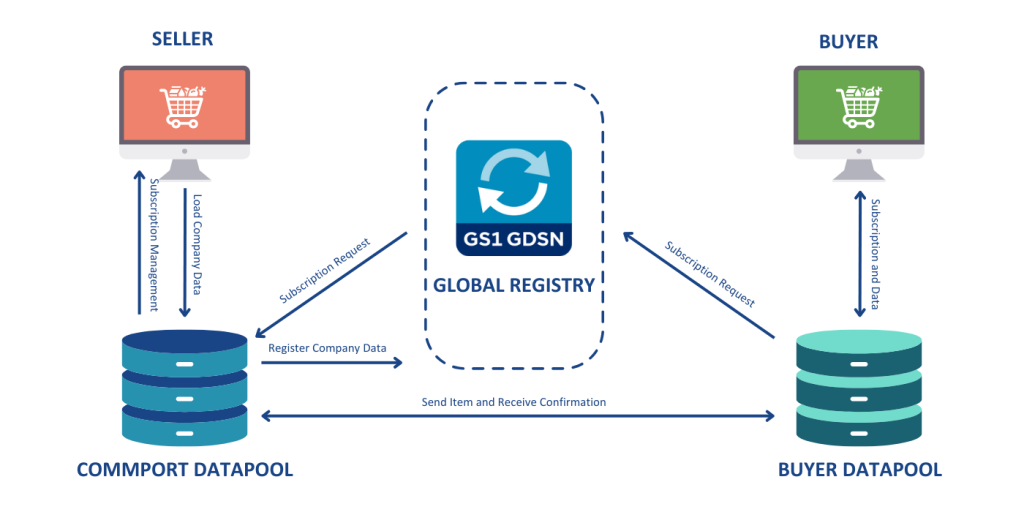

GDSN stands for Global Data Synchronization Network, an online network governed by GS1 standards that enables trading partners to exchange standardized product master data globally. This interconnected network of interoperable data pools follows a publish-subscribe pattern between trading partners. When a manufacturer updates product information, the data is instantly synchronized across all systems, ensuring that every trading partner has access to the same accurate information.

The network operates through a systematic process: manufacturers publish their product data to their chosen GDSN-certified data pool, which validates the information against GS1 standards. Subsequently, this data becomes available to authorized trading partners who have subscribed to receive it. This mechanism creates a “single source of truth” for product information across the entire supply chain.

Role of GTINs and GLNs in Product Identification

Two key identifiers form the foundation of GDSN’s functionality:

Global Trade Item Numbers (GTINs) uniquely identify products and their various packaging levels (e.g., item, case, pallet). Brand owners assign these numbers to all their products and define the associated master data attributes like size, color, and brand information.

Global Location Numbers (GLNs) are 13-digit identifiers that uniquely identify locations or entities within an organization. They ensure warehouses, stores, and even functional departments are uniquely recognized across global supply chains.

Together, these standardized identifiers create a common language that eliminates confusion, reduces errors, and streamlines business transactions throughout the food and beverage industry.

Overview of GS1 Certified Data Pools and Global Registry

The GDSN consists of two primary components: GS1-certified data pools and the GS1 Global Registry.

Data pools function as standards-based repositories for item information, providing users with a single access point to the GDSN. Currently, there are 44 GDSN-certified data pools worldwide, connecting over 35,000 companies. Each offers core GDSN functionality but may differ in additional services and pricing models.

The GS1 Global Registry acts as the network’s “yellow pages,” holding information about data subscriptions, enabling data pool interoperability, and facilitating matchmaking between publishers and subscribers. This centralized directory ensures all participants can locate and access needed information regardless of which data pool they use.

Industry Segments and Product Categories Using GDSN

Across the food and beverage landscape, GDSN adoption continues to gain momentum as companies recognize its value in streamlining operations and enhancing supply chain visibility.

GDSN Adoption in CPG, Grocery, and Fresh Produce

For more than 40 years, the grocery industry has pioneered the adoption of GS1 Standards. Consumer packaged goods (CPG) manufacturers utilize GDSN to synchronize product data seamlessly with retailers. Fresh produce suppliers have embraced these standards to enhance traceability, with 226,226 GTINs currently registered in GDSN data pools for fresh produce items and 4,611 GLNs identifying location points throughout their supply chains.

Furthermore, the produce sector specifically leverages GDSN for “enhanced traceability and preparedness for fast, precise recalls”. Growers, packers, and shippers increasingly use unique product identification to support food safety initiatives while simultaneously improving inventory management practices.

GLN Usage Trends in the Meat, Dairy, and Seafood Sectors

The meat and poultry industry shows strong GDSN implementation with 5,508 GLNs and 901,065 GTINs currently synchronized. Companies in this sector primarily use GS1 Standards “to improve product tracing in support of food safety and supply chain efficiencies”.

Similarly, the dairy industry has registered 5,537 GLNs, with 691,648 dairy product GTINs flowing through GDSN data pools. Consequently, dairy producers are “leveraging existing investments in GS1 Standards to enhance supply chain visibility”.

Meanwhile, seafood suppliers maintain 3,491 GLNs within the system. In fishery and aquaculture supply chains, “the goal of enhanced traceability is to reduce the risk of illegal, unreported, and unregulated seafood”.

Beverage Categories: Soft Drinks, Coffee, Wine, Spirits

Beverage categories maintain an extensive GDSN presence, falling primarily within the broader food/beverage segment of the GS1 classification system. These products benefit from standardized classification through the Global Product Classification (GPC) system, enabling precise categorization of soft drinks, coffee, wine, and spirits.

Non-food categories: Personal care, Pet supplies, Tobacco

Beyond food items, personal care products maintain a significant GDSN footprint with 5,935 GLNs and an impressive 3,774,767 GTINs. Pet supplies (2,487 GLNs, 471,610 GTINs) and tobacco products (1,071 GLNs, 159,878 GTINs) demonstrate how GDSN extends beyond traditional grocery categories, creating standardized data exchange across diverse retail segments.

Implementing GDSN for Food and Beverage Manufacturers

For food and beverage manufacturers, implementing a successful GDSN strategy requires careful planning and execution. The process involves several critical steps that ensure seamless data synchronization with trading partners.

Step 1 - Building GTIN Hierarchies for Multi-Level Packaging

Establishing proper GTIN hierarchies forms the foundation of effective product data synchronization. Each packaging level requires a unique GTIN, from the base unit to cases and pallets. When building these hierarchies, manufacturers must define key indicators for each level:

- Base Unit Indicator – Identifies the lowest hierarchy level with no smaller GTIN-identified units

- Consumer Unit Indicator – Specifies products purchasable by consumers

- Shipping Unit Indicator – Identifies trade items considered shipping units

- Orderable Unit Indicator – Designates products that can be ordered

Step 2 - Selecting a GS1-Certified Data Pool for Synchronization

Choosing the right data pool is crucial for successful implementation. Currently, 44 GDSN-certified data pools connect over 35,000 organizations worldwide. Instead of partnering with the same data pool as your trading partners, select one that best meets your specific needs.

Consider these factors when evaluating data pools:

- Experience with food and beverage implementations

- Support for your specific attribute requirements

- Implementation of best practices sharing

- Geographic coverage matching your markets

Switch to Commport Datapool. A GS1 Certified GDSN Data Pool Since 2005 – with 18 established connections and full GDSN certification, they offer expertise in implementing data synchronization solutions.

Step 3 - Mapping Internal Attributes to GDSN Standard Fields

Once you’ve selected a data pool, map your internal product attributes to standardized GDSN fields. This process ensures your product data conforms to global standards while maintaining alignment with your internal systems.

Step 4 - Conducting Pilot Tests With Trading Partners

Before full implementation, conduct pilot tests with key trading partners. This approach allows you to verify data accuracy and transmission without disrupting ongoing operations.

Step 5 - Establishing SOPs for Ongoing Data Governance

Finally, develop standard operating procedures (SOPs) for maintaining data quality. These procedures should address data validation, updates, and communication protocols with trading partners to ensure the long-term success of your GDSN implementation.

Implementing GDSN for Food and Beverage Distributors and Retailers

On the receiving end of the GDSN ecosystem, distributors and retailers play a crucial role in completing the data synchronization cycle. Their effective implementation ensures accurate product information flows seamlessly from manufacturers to consumers.

Step 1 - Subscribing to Product Data Using GLNs

Global Location Numbers (GLNs) enable distributors and retailers to identify themselves uniquely within the GDSN network. Every business participating in GDSN must have at least one GLN to operate effectively. These 13-digit identifiers function as digital addresses, allowing companies to subscribe to relevant product information from manufacturers. Following GLN assignment, retailers can subscribe to receive updates whenever suppliers publish or modify product data, ensuring continuous access to current information.

Step 2 - Defining Attribute Requirements for Internal Systems

Before implementation, distributors must clearly outline which GDSN attributes they need for their internal systems. This typically begins with mapping exercises to determine where each attribute will reside within the company’s databases. Most organizations prioritize the GDSN Core Attributes as outlined in the GS1 US National Data Quality Program Framework. Besides mandatory attributes, retailers should define additional attributes required for specific business processes, especially those crucial for regulatory compliance.

Step 3 - Cross-Referencing GTINs with Internal Item Codes

For seamless integration, retailers must establish reliable methods to cross-reference received GTINs with their internal item codes. This ensures that incoming GDSN data connects properly with existing product records. Effective cross-referencing creates a unified view of product information across all systems, preventing discrepancies between external and internal data sources.

Step 4 - Data Quality Scorecards and Validation Workflows

Data quality management forms the backbone of successful GDSN implementation. Many retailers implement scorecards to measure three critical aspects of data quality:

- Completeness: Whether required attributes are populated

- Accuracy: Adherence to GS1 standards

- Timeliness: Availability within required timeframes

These scorecards help identify and resolve data discrepancies while fostering opportunities for both parties to improve their data processes. Moreover, establishing clear workflows for data validation allows retailers to review, reject, or synchronize product information systematically.

Conclusion

GDSN adoption continues to grow steadily across all food and beverage segments. Fresh produce operations currently utilize 4,611 GLNs with 226,226 GTINs registered in data pools. Meanwhile, non-fresh produce businesses have implemented 5,831 GLNs and synchronize 496,904 GTINs. The meat and poultry sector demonstrates strong implementation with 5,508 GLNs and an impressive 901,065 GTINs flowing through the system.

Additionally, other segments show significant adoption rates. Dairy producers maintain 5,537 GLNs with 691,648 GTINs, while bakery operations utilize 7,340 GLNs and 803,176 GTINs. Seafood suppliers currently employ 3,491 GLNs with 241,551 GTINs synchronizing across the network.

Beyond traditional food categories, GDSN extends into adjacent retail segments. Personal care and beauty products maintain 5,935 GLNs with a substantial 3,774,767 GTINs. Pet supplies account for 2,487 GLNs and 471,610 GTINs, while tobacco products utilize 1,071 GLNs with 159,878 GTINs. The broader “other food” category represents the largest segment with 25,405 GLNs and 5,366,874 GTINs currently synchronized.

Beverage categories likewise benefit from GDSN implementation, with soft drinks, coffee, tea, wine, beer, whiskey, and spirits all streamlining their data exchange through this global network.

Companies that effectively implement GDSN gain significant competitive advantages. First, they ensure accurate product representation across all retail channels. Second, they reduce costly data errors that lead to returns and consumer dissatisfaction. Third, they establish the foundation for regulatory compliance, particularly important given increasing demands for transparency in food labeling.

Looking ahead, GDSN will undoubtedly play an even more crucial role as consumer expectations for product information continue to rise. The 81% of shoppers willing to switch brands for better information represents both a challenge and opportunity for food and beverage companies.

Therefore, businesses that haven’t yet implemented GDSN should certainly consider its adoption. Those already using the network should focus on optimizing their data quality and expanding attribute coverage to meet evolving market demands. After all, GDSN doesn’t just synchronize data—it synchronizes business success throughout the entire food and beverage ecosystem.

Commport GDSN Datapool

Download: GDSN Buyers Guide

Empower your business with global data synchronization; download our GDSN Buyer's Guide today and take the first step towards streamlined, accurate, and compliant product data management.

Frequently Asked Questions

GDSN stands for Global Data Synchronization Network. It’s a standardized system that allows companies in the food and beverage industry to share accurate product information efficiently across their supply chains, ensuring consistency from production to retail.

GDSN ensures that consumers have access to accurate and detailed product information. This transparency allows shoppers to make informed decisions about the products they purchase, which is particularly important for those with dietary restrictions or specific preferences.

GTINs (Global Trade Item Numbers) uniquely identify products and their packaging levels, while GLNs (Global Location Numbers) identify specific locations or entities within an organization. These standardized identifiers are crucial for accurate product tracking and data exchange in the GDSN system.

Effective GDSN implementation for manufacturers involves building proper GTIN hierarchies, selecting a certified data pool, mapping internal attributes to GDSN standards, conducting pilot tests with trading partners, and establishing ongoing data governance procedures.

Retailers and distributors should focus on subscribing to product data using GLNs, defining attribute requirements for their internal systems, cross-referencing GTINs with internal item codes, and implementing data quality scorecards and validation workflows to ensure accurate and timely product information.