Introduction

What is SKU?

Surprisingly, this simple acronym introduced in the 1930s has transformed how businesses manage inventory worldwide.

Grocery stores that carried just 7,000 SKUs in 1970 now manage more than 31,000 as of 2022.

SKU stands for Stock Keeping Unit – essentially a unique identifier assigned to products for inventory tracking purposes.

These codes, typically consisting of numbers and letters, are the fundamental building blocks of warehouse, factory, and retail store inventory management.

However, poor SKU management comes at a cost – insufficient demand for specific SKUs can increase product costs by an additional 15% to 40% annually.

A well-structured SKU system allows businesses to identify products quickly, monitor stock levels in real time, and avoid common supply chain problems like overstocking.

Since two products that differ in any way cannot share the same SKU code, these identifiers have become critical for modern retail operations.

In this guide, we’ll break down everything you need to know about SKUs – from basic definitions to practical examples that will help you implement an effective system for your business.

Key Takeaways

- SKUs are customizable internal codes– Unlike UPCs, you create your own 8-12 character alphanumeric system tailored to your business needs

- Follow a logical structure– Organize SKUs from general to specific (department-product-attributes-sequence) for easy recognition and inventory tracking

- Avoid common creation mistakes– Never start with zeros, use confusing characters, or reuse old SKU numbers, as these cause system errors

- Implement SKU rationalization regularly– Analyze underperforming products using the 80/20 rule to eliminate inventory that contributes little to sales

- Integrate SKUs with POS systems– Proper integration enables real-time inventory tracking, accurate order fulfillment, and seamless multi-channel operations

What is a SKU? Meaning and Definition

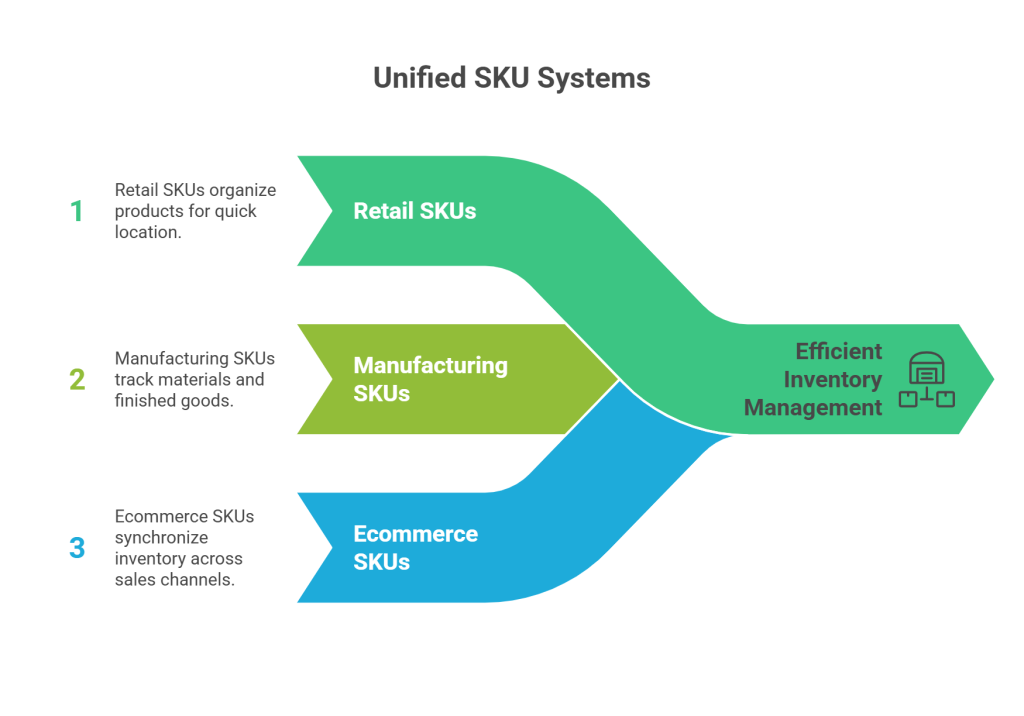

A Stock Keeping Unit (SKU) serves as the foundation of inventory management systems across retail, manufacturing, and e-commerce businesses. Understanding SKUs enables businesses to track products efficiently, maximize sales, and minimize losses.

What Does SKU Stand For?

SKU stands for Stock Keeping Unit. Most commonly pronounced as “skew” (and sometimes as “es-kay-you”), this abbreviation represents the fundamental unit of measure in inventory management. This alphanumeric code is created internally by sellers to identify, track, and locate their product inventory.

Unlike other product identifiers, SKUs are customizable and specific to each business. They typically consist of 8-12 characters that combine letters and numbers in a meaningful pattern. The beauty of SKUs lies in their flexibility – each business can design its own SKU system based on its unique inventory management needs.

What is a Stock Keeping Unit in Business?

In practical business terms, a stock-keeping unit represents a distinct type of item for sale, purchase, or tracking in inventory. Each SKU identifies a specific product and all product attributes that distinguish it from other items, including:

- Manufacturer information

- Product description

- Material composition

- Size specifications

- Color variations

- Packaging details

- Warranty terms

When businesses conduct inventory counts, they track the quantity of each unique SKU. Additionally, SKUs enable retailers to restock inventory efficiently as products sell, allowing for precise tracking throughout the supply chain.

Most importantly, SKUs facilitate the quick identification of product details. For example, a clothing retailer might use a code like “WREN101REDSM” to represent a red, small sweatshirt from the brand Wren. By examining this code, employees can immediately recognize that “WREN” identifies the brand, “101” represents the sweatshirt category, “RED” indicates the color, and “SM” specifies the size.

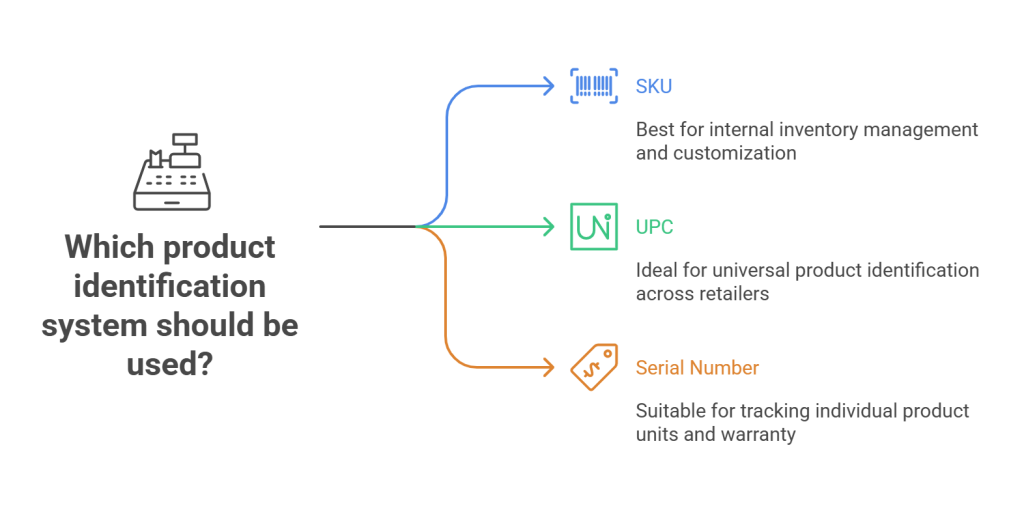

SKU vs UPC vs Serial Number

These three identification systems often cause confusion due to their similar appearances on product packaging. Nevertheless, they serve distinct purposes:

SKU (Stock Keeping Unit):

- Created and used internally by retailers

- Varies between different stores selling the same product

- Usually contains both letters and numbers

- Primarily tracks inventory and sales within a single business

UPC (Universal Product Code):

- Standardized 12-digit numeric code

- Remains consistent across all retailers selling the product

- Created by the manufacturer, not customizable by retailers

- Often displayed as a scannable barcode

Serial Number:

- Unique to each individual product unit (not just the model)

- Created by the manufacturer, not customizable by retailers

- Used to track warranty information and product authentication

- Helps manage recalls and repairs for specific items

Fundamentally, the key difference lies in their scope: SKUs help retailers organize their specific inventory, UPCs identify products universally across all retailers, and serial numbers track individual product units throughout their lifecycle.

Small businesses often adopt UPCs as their SKUs to simplify their inventory tracking process. Nevertheless, as businesses grow and product lines expand, creating a customized SKU system becomes increasingly beneficial for detailed inventory management and reporting.

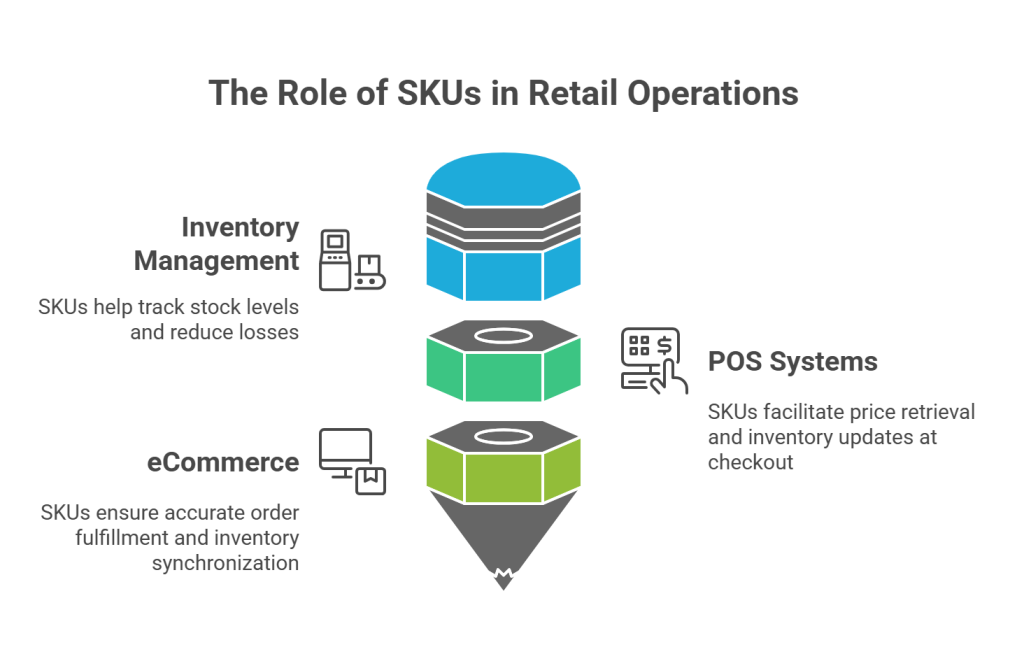

How SKUs Work in Inventory and Retail

Beyond basic definitions, SKUs power modern retail operations through sophisticated tracking systems. These alphanumeric codes transform how businesses monitor products from warehouse shelves to shopping carts, creating a seamless inventory management experience.

How SKUs Help Track Inventory

SKUs serve as the foundation of effective inventory management, functioning almost like a GPS for your products. With properly implemented SKU systems, businesses can:

Monitor stock levels in real time, preventing both empty shelves and excess inventory

Reduce “phantom inventory” – items that appear available in systems but are actually missing from warehouses

Identify shrinkage issues, which are projected to cause $132 billion in global retail losses in 2024, up from $112 billion in 2022

Through SKU tracking, warehouse staff can efficiently sort incoming shipments, restock shelves, and locate specific products. This level of inventory visibility allows managers to make data-driven decisions about which products need immediate reordering based on actual sales patterns rather than guesswork.

Furthermore, SKUs help businesses prepare for seasonal demand fluctuations. By analyzing SKU-level performance data over time, companies can identify which items experience seasonal popularity shifts, enabling them to adjust inventory levels and storage locations accordingly.

SKU Meaning in POS Systems

When a customer purchases an item, the SKU becomes the crucial link between the physical product and your digital inventory system. At checkout, scanning the SKU through a Point-of-Sale (POS) system triggers several simultaneous actions:

The system retrieves the correct price information The transaction is recorded in sales data The item is automatically removed from available inventory

This automation eliminates manual counting errors while giving businesses real-time visibility into inventory movement. Consequently, managers can instantly see which products are selling quickly and require restocking.

Additionally, pairing SKUs with integrated POS systems allows employees to look up product information rapidly, answering customer questions about availability, specifications, or pricing on the spot. This capability enhances customer service while reducing staff training time, as employees don’t need to memorize details about every product.

Why SKUs Matter in eCommerce

In the digital marketplace, SKUs become even more critical as customers can’t physically inspect products. Properly managed SKUs ensure:

Accurate order fulfillment – guiding shipping staff to select precisely the right product variation Cross-channel inventory synchronization – maintaining consistency whether customers shop on your website, through marketplaces like Amazon, or in physical stores. Enhanced customer experience – enabling personalized product recommendations and substitutions for out-of-stock items

Above all, eCommerce businesses benefit from SKUs when connecting their online listings with inventory records. This integration gives customers the most current view of product availability while helping sellers track different product varieties across multiple sales channels.

For subscription services or businesses filling multi-product orders, SKU tracking ensures each package contains the correct items, building brand loyalty through consistent order accuracy. Coupled with automated inventory management systems, SKUs allow online retailers to scale their operations while maintaining precise control over increasingly complex product catalogs.

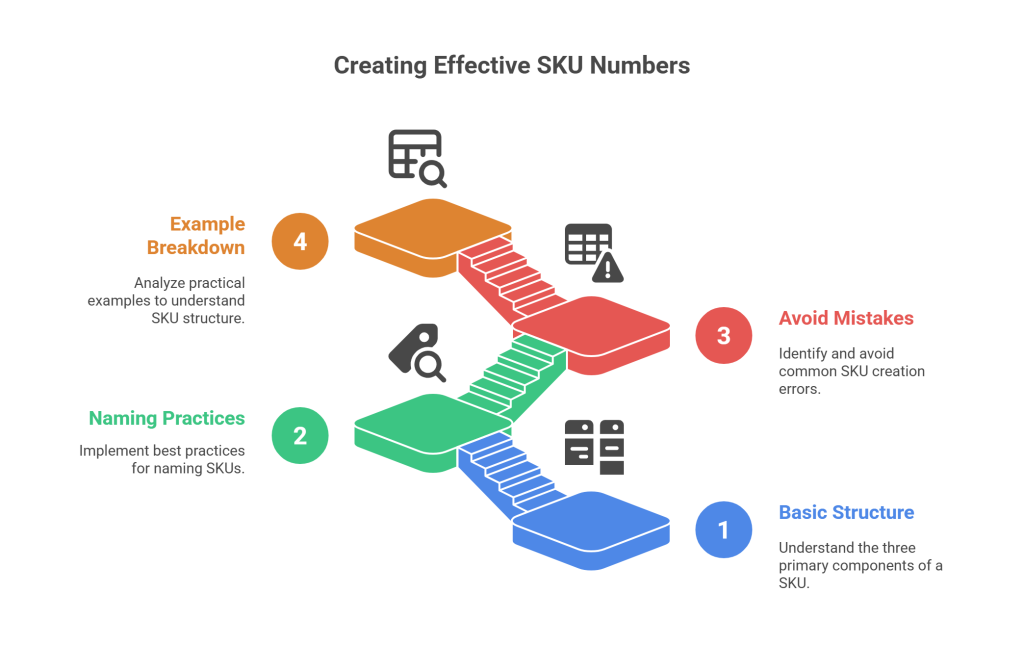

How to Create a SKU Number

Creating effective SKU numbers might appear complicated initially, but with a systematic approach, this process becomes straightforward. A well-designed SKU system streamlines inventory management while providing valuable product insights.

Basic Structure of a SKU

Every SKU consists of three primary components that work together to create a unique product identifier:

- Top-level identifier: The first 2-3 characters represent your broadest classification – typically a department, product category, or supplier. This provides immediate basic information about the product.

- Middle section: These characters represent unique product attributes like size, color, or subcategory. This middle portion helps distinguish between product variations.

- Sequential number: The final characters often use a sequential numbering system (001, 002, 003) to identify when items arrived in inventory or to differentiate between similar products.

This hierarchical structure ensures each product has a unique identifier while maintaining logical organization across your inventory.

Best Practices for Naming SKUs

To maximize the effectiveness of your SKU system:

- Keep SKUs between 8-12 characters – long enough to be descriptive but short enough to be practical

- Use alphanumeric codes instead of only numbers or only letters

- Arrange information from general to specific (most important attributes first)

- Maintain consistency in your format across all products

- Use standard prefixes for categories or departments

- Avoid using spaces – use hyphens or underscores instead if needed

- Choose meaningful abbreviations your team can easily recognize

Commport Datapool Solutions for Electronic Commerce helps you centralize, enrich, and sync your SKUs to multiple marketplaces and trading partners in one click! This streamlines your SKU management across all sales channels.

Common Mistakes to Avoid

During the SKU creation process, watch out for these potential pitfalls:

- Starting with zero: Many systems interpret leading zeros as “nothing,” potentially corrupting your SKU data

- Using confusing characters: Avoid letters that look like numbers (O vs. 0, I vs. 1) to prevent misreading

- Including special characters: Characters like @, #, or & can cause technical issues in many inventory systems

- Inconsistent naming conventions: Switching formats between products creates confusion

- Reusing old SKU numbers: This practice can lead to historical data loss and inventory errors

- Creating overly complex codes: If your team can’t easily interpret your SKUs, they lose much of their value

SKU Number Example Breakdown

Let’s examine a practical example from a clothing retailer:

For a blue Nike running shoe in women’s size 10, the SKU might be: NIK-RN-BL-10W

Breaking this down:

- NIK: Brand identifier (Nike)

- RN: Product type (Running shoe)

- BL: Color code (Blue)

- 10W: Size and gender specification (Size 10, Women’s)

For comparison, consider a different approach for a red Gap women’s denim jacket in size Large: GP-JN-F-L-RED

This logical structure allows anyone familiar with your system to understand key product details without additional reference materials instantly.

Real-World SKU Examples and Use Cases

Looking at SKUs in action across different industries reveals their versatility and practical applications. These alphanumeric codes serve as the backbone of inventory systems throughout various business sectors, each with unique implementation approaches.

Retail SKU Example

Walking into any retail store, you’ll encounter SKUs on virtually every product label. In clothing retail, brands like Lee utilize a structured approach to their SKU system. Specifically, Lee employs a 7-digit SKU where the first 5 digits determine the product style followed by 2 digits indicating color.

For apparel items, retail SKUs often follow a pattern that represents multiple product characteristics:

- 41-VER-FLY-S-001: A dress (41) by Vera Bradley (VER) in the “Fly” style, size small (S), with sequence number 001

- TS-BLM-A101: A blue medium t-shirt (TS-BLM) from Brand A’s King series (A101)

- GP-JN-F-L-RED: A red Gap denim jacket in women’s large size

Department stores typically create SKUs to organize diverse product lines, such as MEN-SHOES-001 for men’s footwear. These codes allow staff to quickly locate items on shelves, improving customer service by enabling immediate answers to product availability questions.

Manufacturing SKU Example

Throughout manufacturing environments, SKUs track both raw materials and finished products. Intel, as an illustration, uses manufacturing part numbers (a type of SKU) to monitor their processors throughout production.

A typical manufacturing SKU might look like: RIFLE-14-A4-BLU – representing a Rifle brand (manufacturer) notebook in the paper supplies category (14), A4 size, with a blue cover.

For automotive parts, SKUs often incorporate vehicle compatibility information. Consider Aa-rak-1-2010-Hd which represents an Alloy Art (Aa) rear axle kit (rak) that’s 1-inch in size for a 2010 Harley Davidson motorcycle.

Ecommerce SKU Example

Online retailers primarily use SKUs to synchronize inventory across multiple sales channels. Amazon, notably, publishes specific SKU guidelines for third-party sellers participating in their Fulfillment by Amazon program, ensuring standardization across millions of products.

E-commerce SKUs commonly help categorize products for better customer recommendations. When shoppers browse cotton clothing items online, the store can suggest similar products by matching SKU patterns. Digital businesses selling memberships may also use unique SKUs to differentiate between membership durations that share the same product name.

An online bookstore might employ BOOK-FIC-0456 to identify a specific fiction title, streamlining order processing. This systematic approach allows e-commerce businesses to maintain precise inventory tracking across diverse categories while ensuring accurate fulfillment.

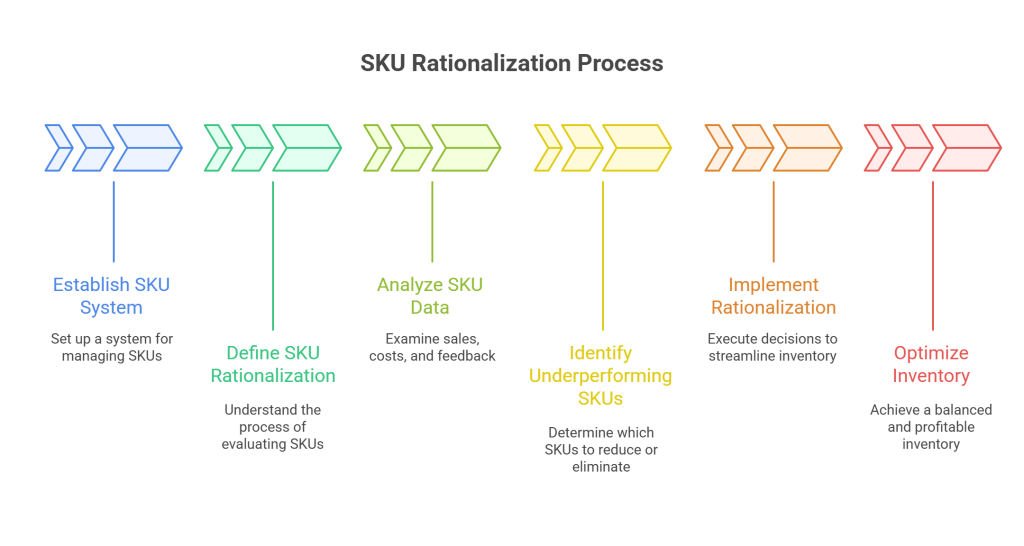

What is SKU Rationalization and Why It Matters

After establishing your SKU system, the next crucial step is optimizing it. For businesses with expanding product catalogs, SKU rationalization becomes increasingly vital for maintaining operational efficiency.

Definition of SKU Rationalization

SKU rationalization is an analytical process that evaluates products in your inventory to determine which items to keep, reduce, or eliminate. T

his systematic approach measures product profitability using metrics like inventory holding costs, procurement fees, fulfillment expenses, and historical sales data. In essence, it’s a strategic method to pare down inventory and make educated decisions about which SKUs deserve continued investment.

Benefits of Reducing SKU Clutter

Streamlining your SKU portfolio offers numerous advantages:

- Reduced inventory costs and freed warehouse space by eliminating slow-moving items

- Improved cash flow through optimized inventory levels

- Enhanced operational efficiency with simplified inventory management

- Increased profitability by focusing resources on high-performing products

Unilever discovered that SKU variance in their UK and Ireland operations accounted for 20% of inventory but contributed only 5% to sales. Moreover, focusing on top performers aligns with the 80/20 rule (Pareto principle), which suggests approximately 80% of sales typically come from just 20% of products.

How to Identify Underperforming SKUs

Commport Datapool Solutions for Electronic Commerce helps you centralize, enrich and sync your SKUs to multiple marketplaces and trading partners in one click! This capability becomes especially valuable when conducting SKU analysis.

To identify candidates for rationalization, examine:

- Sales velocity and historical performance data

- Inventory turnover rates and carrying costs

- Return rates and customer feedback

- Profitability margins after accounting for all costs

Using SKU Data for Better Decisions

SKU-level data provides granular insights that empower smarter business decisions. When properly analyzed, this information helps:

- Identify bundling opportunities for slow-moving items with bestsellers

- Determine optimal product mix based on profitability metrics

- Guide resource allocation toward high-performing SKUs

- Inform development of new products to replace underperformers

Ultimately, the goal is creating a balanced, profit-generating inventory that maximizes warehouse space while meeting customer demands effectively.

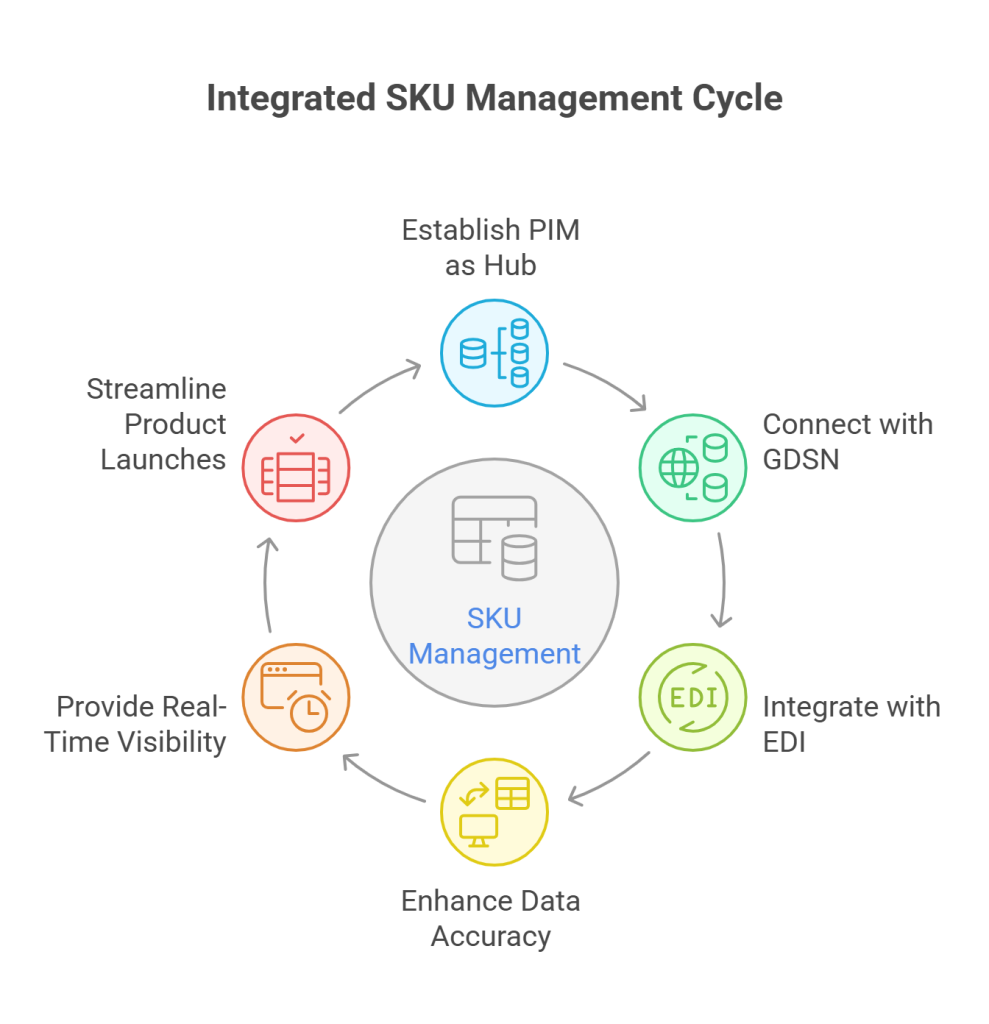

The Power of EDI, GDSN and PIM Integration for SKU Management

When EDI, GDSN, and PIM work together as an integrated system, they create a powerful SKU management solution that addresses fundamental challenges that arise when these systems operate in isolation.

Enhanced Data Accuracy and Consistency

By establishing PIM as the central hub for SKU information and connecting it with GDSN for standardized distribution and EDI for transactional updates, businesses create a single source of truth for product data. This integration:

- Eliminates duplicate entries and inconsistencies across systems

- Reduces data entry errors through automation

- Ensures all stakeholders have access to the same, accurate SKU information

- Maintains data integrity throughout the product lifecycle

Real-Time Visibility and Synchronization

An integrated approach provides unprecedented visibility into your SKU ecosystem:

- Real-time inventory updates across all sales channels

- Instant synchronization of price changes and product specifications

- Automated alerts for low stock levels or inventory discrepancies

- Seamless communication of SKU changes to all trading partners

Streamlined Product Launches and Updates

The combined power of these systems transforms how businesses introduce new SKUs or update existing ones:

- Automated validation ensures new SKUs meet all data requirements before distribution

- Simultaneous updates across all channels and trading partners

- Reduced time-to-market for new products

- Consistent product information across all customer touchpoints

Conclusion

SKUs have truly transformed inventory management since their introduction in the 1930s. Though simple in concept, these alphanumeric codes serve as the backbone of modern retail operations, enabling businesses to track products efficiently from warehouses to shopping carts.

Understanding SKUs provides numerous advantages for your business. First and foremost, these unique identifiers allow quick product recognition and real-time stock monitoring. Additionally, they help prevent common supply chain issues like overstocking while maximizing sales potential.

Creating an effective SKU system requires careful planning. Remember to maintain consistency, use meaningful abbreviations, and follow a logical structure that moves from general to specific information. Above all, avoid pitfalls such as starting with zeros, using confusing characters, or creating overly complex codes that staff cannot easily interpret.

SKU rationalization deserves equal attention as your product catalog grows. This analytical process helps eliminate underperforming items, reduce inventory costs, and free up valuable warehouse space. Consequently, you can focus resources on high-performing products that generate the most profit.

Whether you manage a small retail store, manufacturing facility, or growing e-commerce business, implementing a thoughtful SKU strategy will significantly improve your inventory management capabilities. The right system streamlines operations, enhances customer experiences, and ultimately contributes to your bottom line.

We hope this guide has provided valuable insights into SKU systems and their practical applications. Start implementing these principles today, and you’ll soon see improvements in your inventory efficiency and overall business performance.

Commport Datapool Solutions

Download: GDSN Buyers Guide

Empower your business with global data synchronization; download our GDSN Buyer's Guide today and take the first step towards streamlined, accurate, and compliant product data management.

Frequently Asked Questions

A SKU, or Stock Keeping Unit, is a unique identifier assigned to products for inventory tracking. It’s crucial for businesses as it allows them to monitor stock levels, streamline order fulfillment, and make data-driven decisions about inventory management.

While SKUs are created internally by retailers for inventory management, UPCs are standardized codes used universally across retailers. Serial numbers, on the other hand, identify individual product units. SKUs are customizable and specific to each business, unlike UPCs and serial numbers.

An effective SKU system should use 8-12 alphanumeric characters, arranged from general to specific information. It’s important to maintain consistency, use recognizable abbreviations, and avoid common mistakes like starting with zeros or using confusing characters.

For e-commerce, SKUs are vital for accurate order fulfillment, cross-channel inventory synchronization, and enhancing customer experience through personalized product recommendations. They also help in maintaining consistency across multiple sales platforms.

SKU rationalization is the process of evaluating and optimizing your product inventory. It’s important because it helps reduce inventory costs, improve cash flow, enhance operational efficiency, and increase profitability by focusing resources on high-performing products.